A kind of antistatic coating mold and the gluing process used for this mold

An anti-static and coating technology, applied in the field of gluing process and anti-static coating mold, can solve problems such as reducing convenience, and achieve the effect of reducing the quantity of glue, improving quality and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

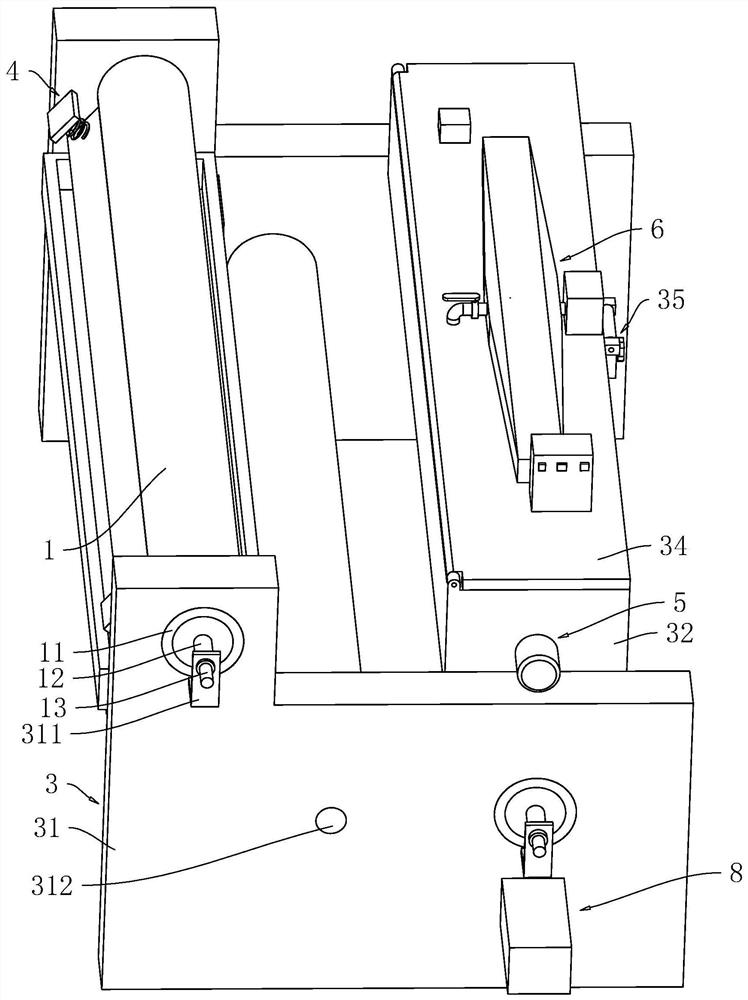

[0046] The present application will be described in further detail below in conjunction with drawings 1-6.

[0047] The embodiment of the present application discloses an antistatic coating mold.

[0048] In this embodiment, the model of the temperature detector 323 is TC4S / H / M / L, and the model of the pressure detector 64 is SIN-P300.

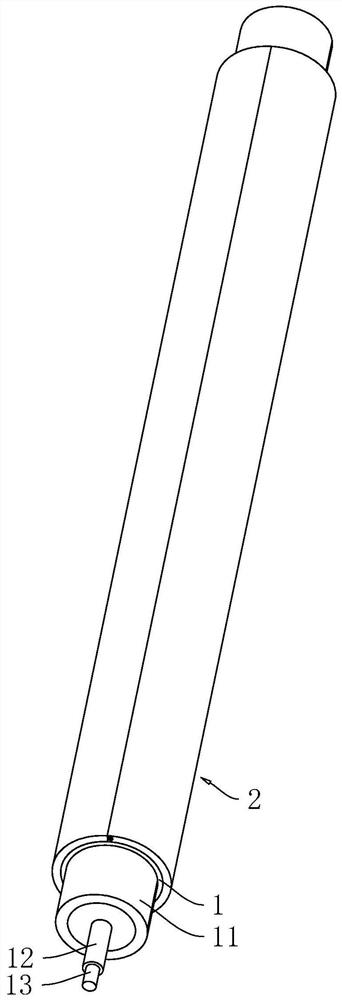

[0049] refer to figure 1 , the antistatic coating mold includes an electrostatic roller 1, and the two ends of the electrostatic roller 1 are coaxially fixed with a connecting roller 11; the two connecting rollers 11 are coaxially rotated and installed with an installation tube 12, and the installation tube 12 and the electrostatic roller 1 For electrical connection, one end of the installation pipe 12 away from the connecting roller 11 is fixedly installed with a grounding wire 13 connected to the power supply, and the grounding wire 13 is electrically connected with the electrostatic roller 1 .

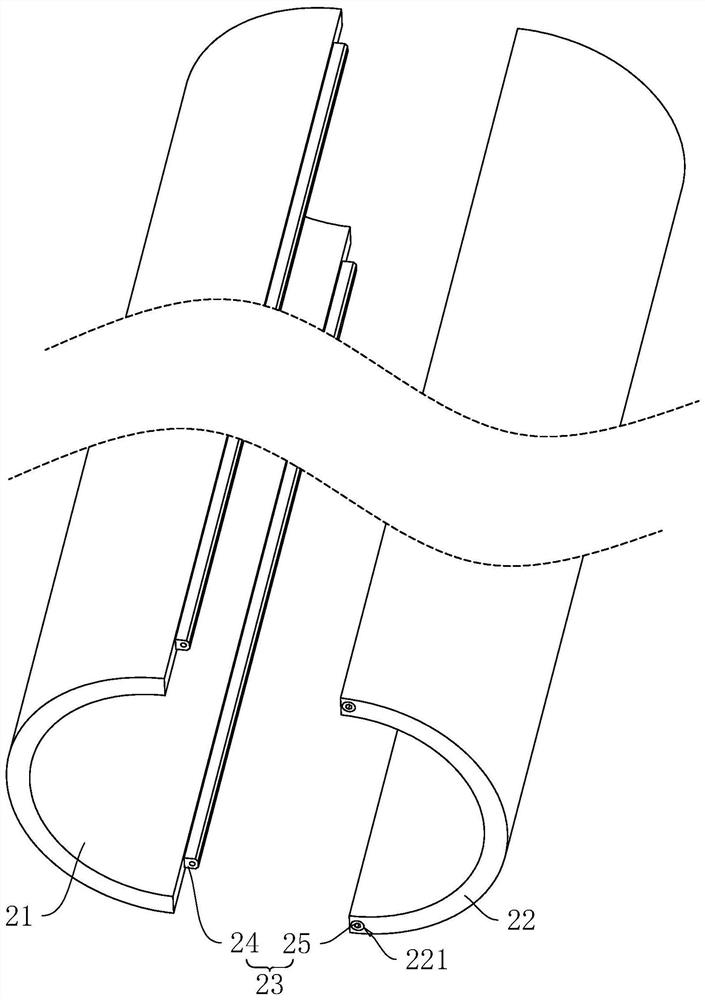

[0050] refer to figure 1 and figure 2 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com