Multi-channel double-end gluing machine

A gluing machine and multi-channel technology, which is applied in the direction of coating and liquid coating on the surface, can solve the problems of low automation, low gluing efficiency, and poor applicability, and achieve high automation and gluing Fast, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

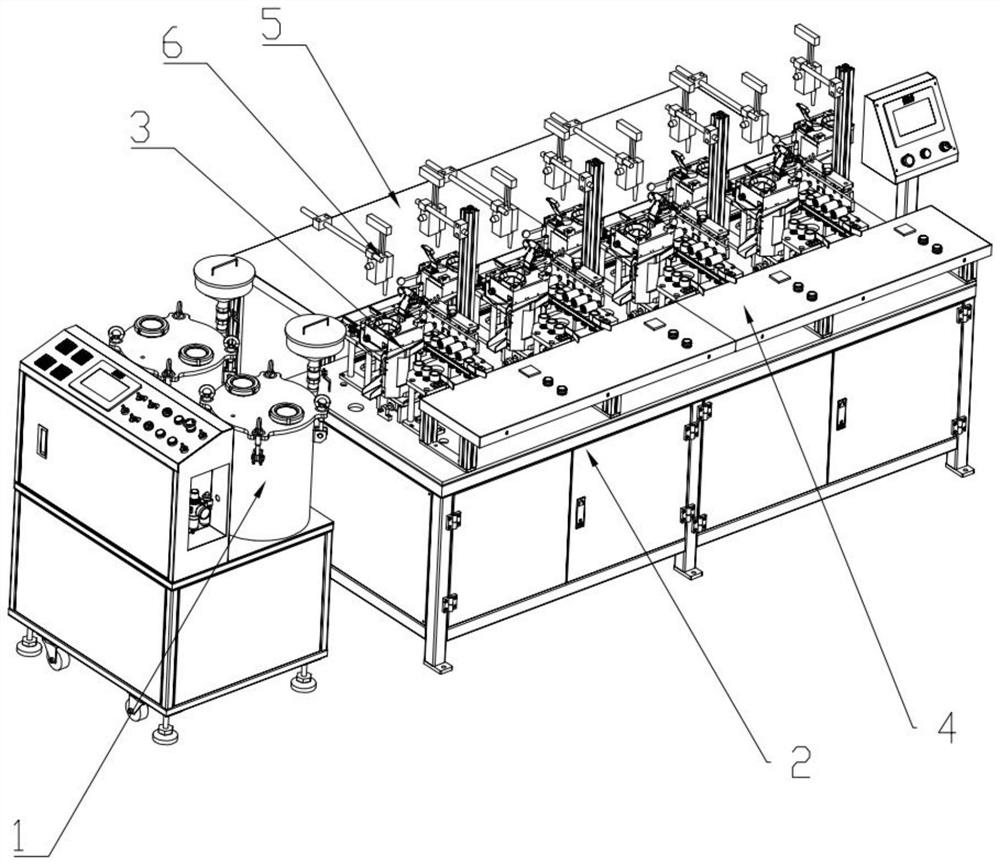

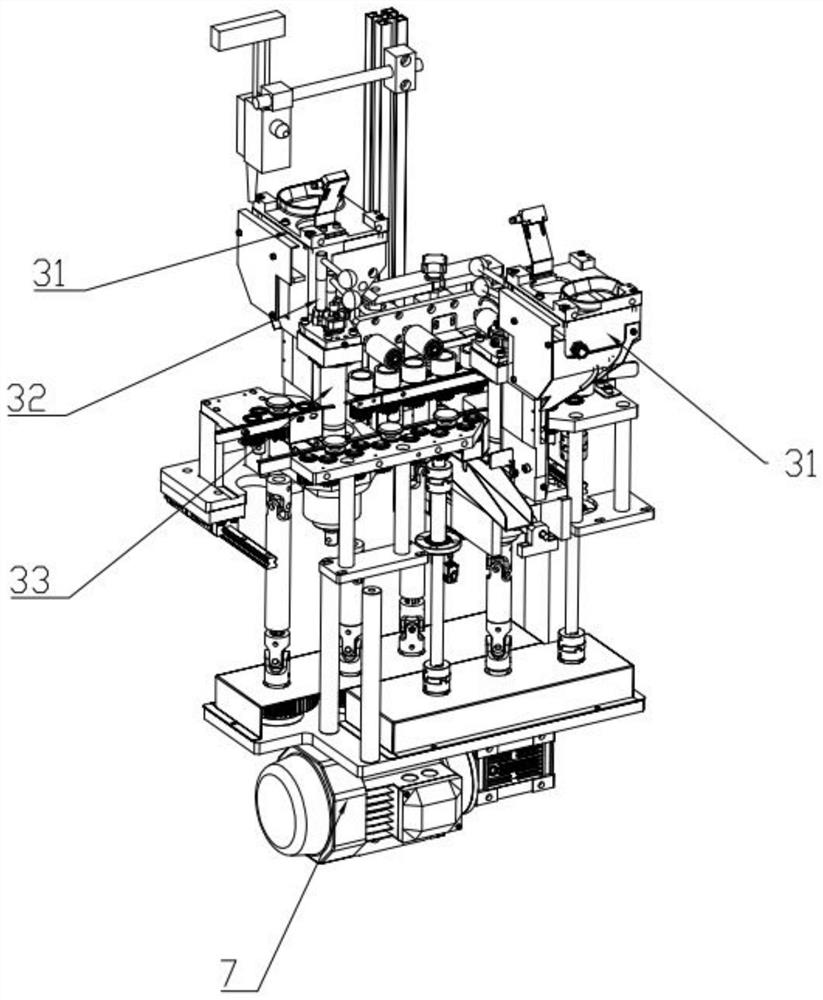

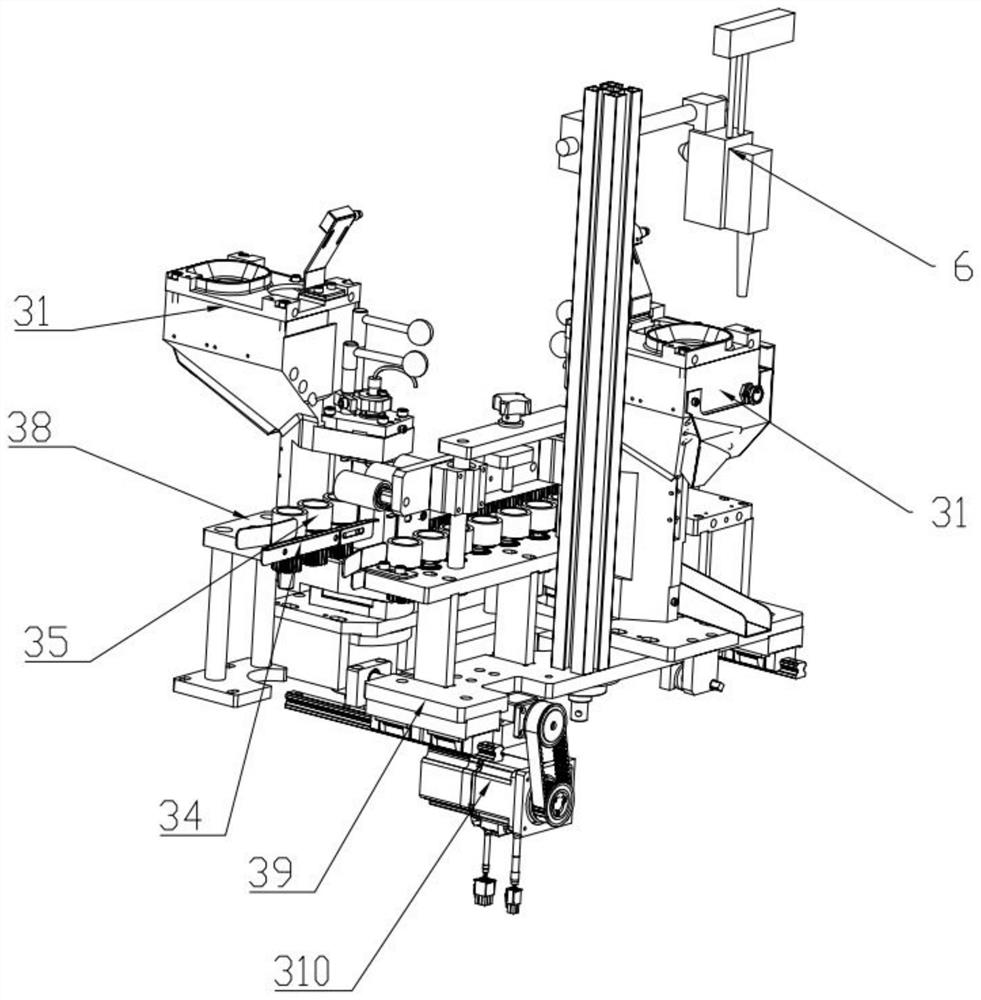

[0024] refer to Figure 1 to Figure 8 , a kind of multi-channel double-end gluing machine described in the present invention, comprises melting glue boiler 1, gluing frame 2, a plurality of gluing mechanism 3 that is installed on the gluing frame 2, feeding platform 4 and Discharging platform 5, the feeding platform 4 and the discharging platform 5 are respectively located on both sides of the gluing mechanism 3, and each gluing mechanism 3 corresponds to a station, which can realize multi-station operation. The glue boiler 1 is connected to multiple feeding nozzles 6 through pipelines. The sol boiler sets the temperature within a certain range. The melt glue boiler 1 heats the glue and sends it to the feeding nozzle 6. The feeding nozzle 6 then adds the glue to the glue application mechanism 3 for use. . The gluing mechanism 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com