Automobile part machining metal stamping equipment capable of automatically feeding and discharging

A technology of auto parts and metal stamping, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of affecting the processing of auto parts, wasting time, and low safety, so as to reduce the workload, avoid self-operation, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

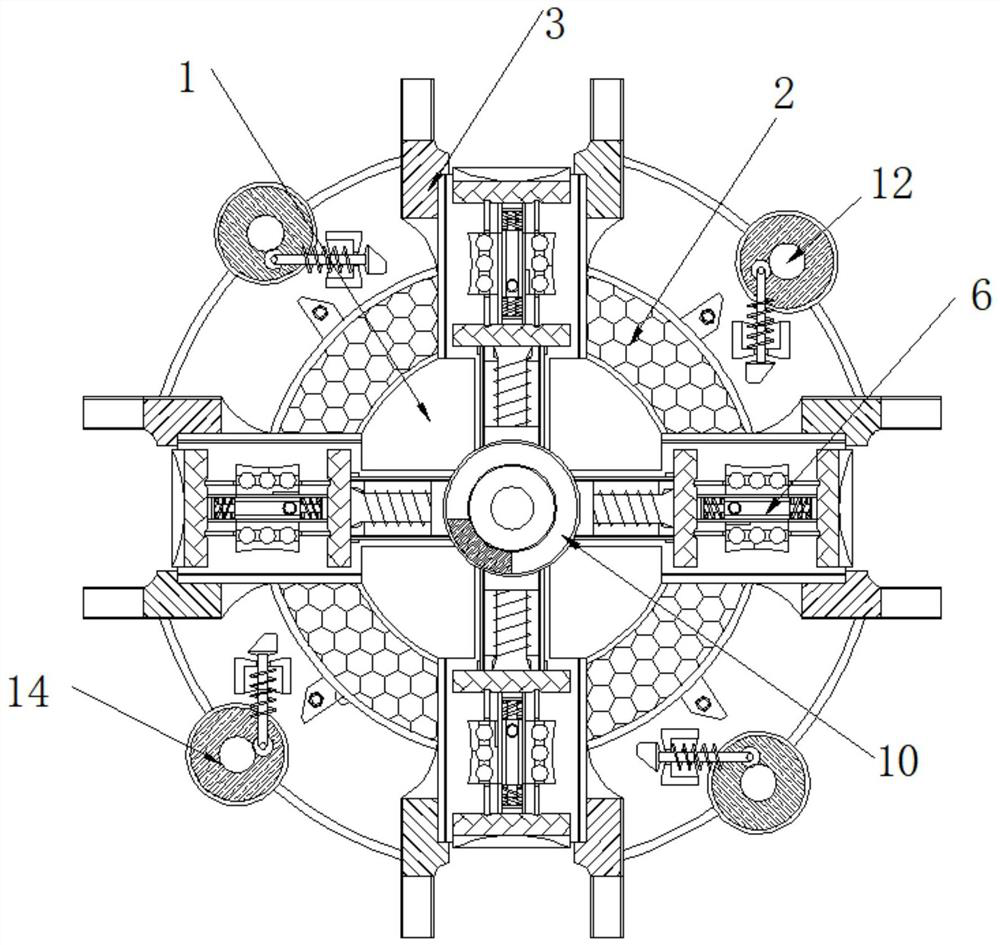

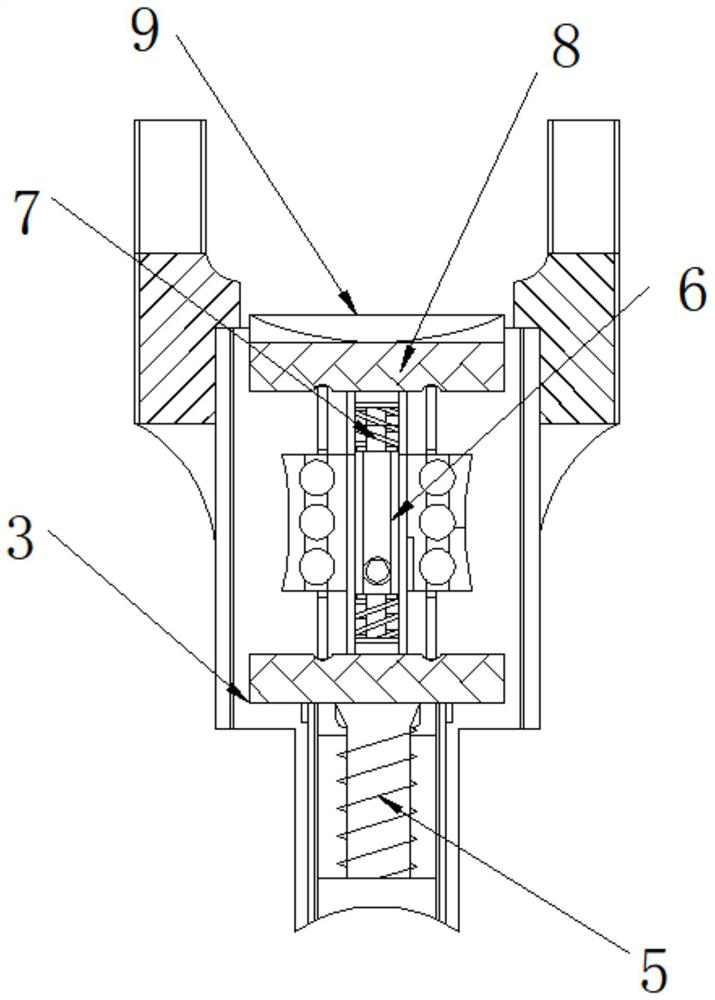

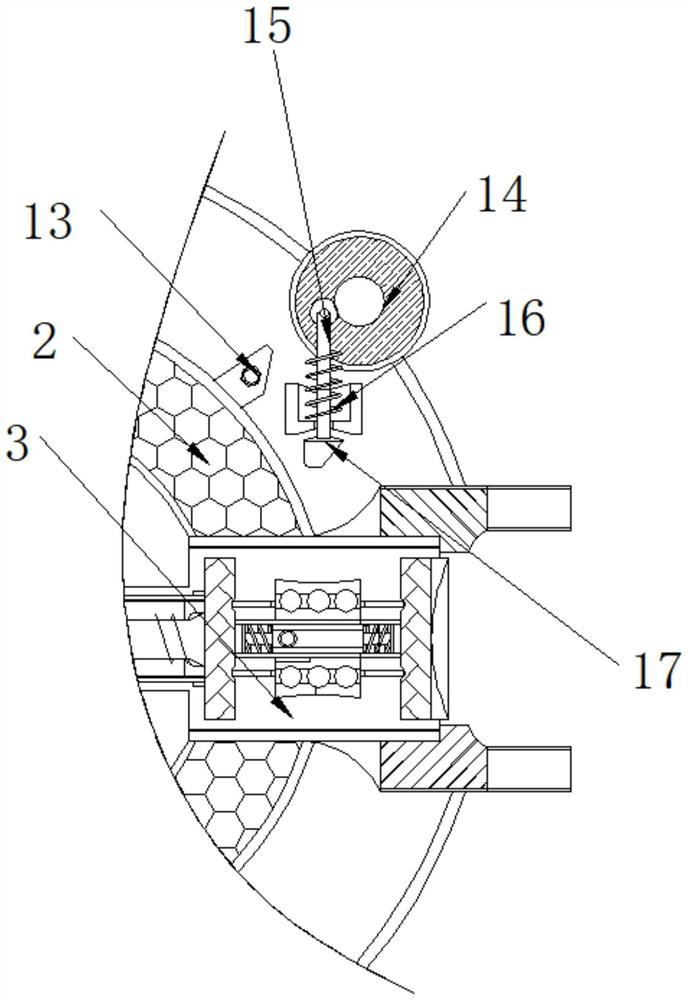

[0020] as attached figure 1 to attach Figure 4 Shown:

[0021] The invention provides a metal stamping equipment for auto parts processing that can automatically load and unload metal stamping equipment, including a processing seat 1, a rotating disk 2 is connected to the inside of the processing seat 1, and a protective frame 3 is fixedly connected to the outer surface of the rotating disk 2. The inside of the frame 3 is provided with a conveying pipeline 4, the inside of the protective frame 3 is movably connected with a compression rod 5, the side surface of the compression rod 5 is movably connected with an elastic frame 6, the outer surface of the protective frame 3 is fixedly connected with a limit frame, and the compression rod 5 The side surface of the elastic frame 6 is movably connected with an elastic spring, and the inside of the elastic frame 6 is movably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com