Aerated concrete isometric block equipment for eco-friendly construction

A technology of aerated concrete and construction, applied in metal processing, ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult cutting and inconvenient movement, and achieve the effect of automatic blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

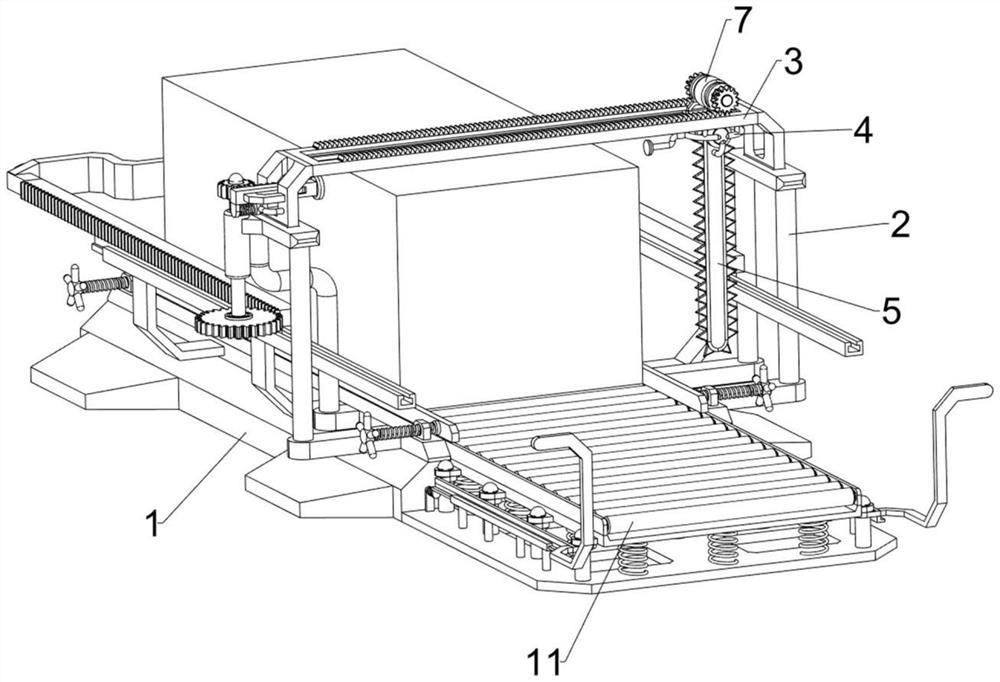

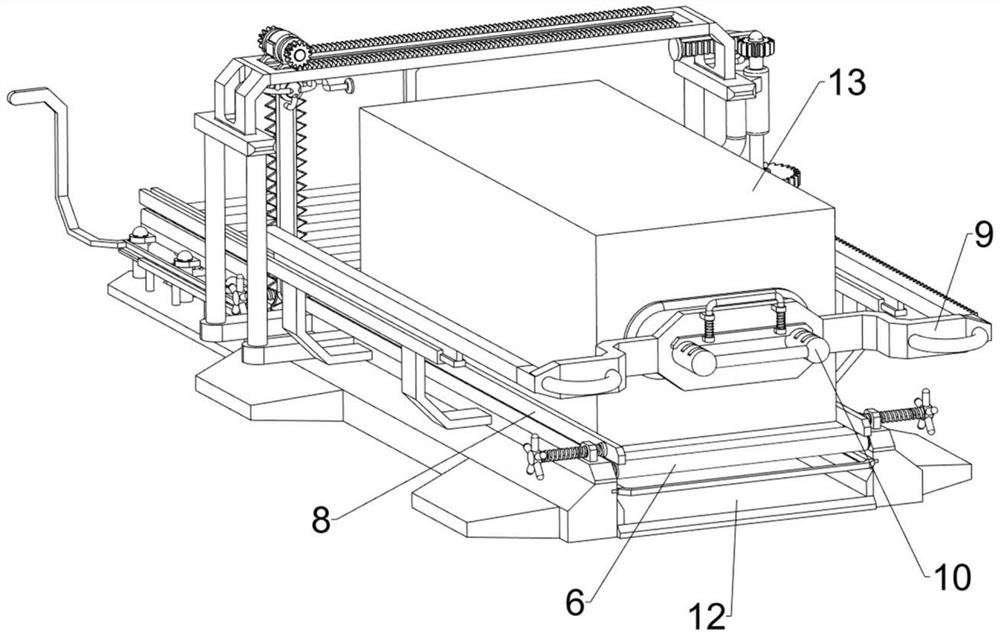

[0028] Aerated concrete isometric block equipment for eco-friendly construction such as Figure 1-4 As shown, it includes a bottom plate 1, a fixed frame 2, a first guide rail frame 3, a first mounting frame 4, an electric cutting saw 5, a rotating roller 6, a reciprocating mechanism 7 and a width adjustment mechanism 8, and the left and right sides of the front part of the bottom plate 1 are all A fixed frame 2 is connected, and a first guide rail frame 3 is connected between the tops of the fixed frame 2, and a first mounting frame 4 is slidably connected to the first rail frame 3, and an electric cutting saw 5 is arranged on the first mounting frame 4. 1 The upper part is uniformly rotatably connected with a roller 6, a reciprocating mechanism 7 is provided between the first rail frame 3 and the first installation frame 4, and a width adjustment mechanism 8 is provided on the rear side of the bottom plate 1.

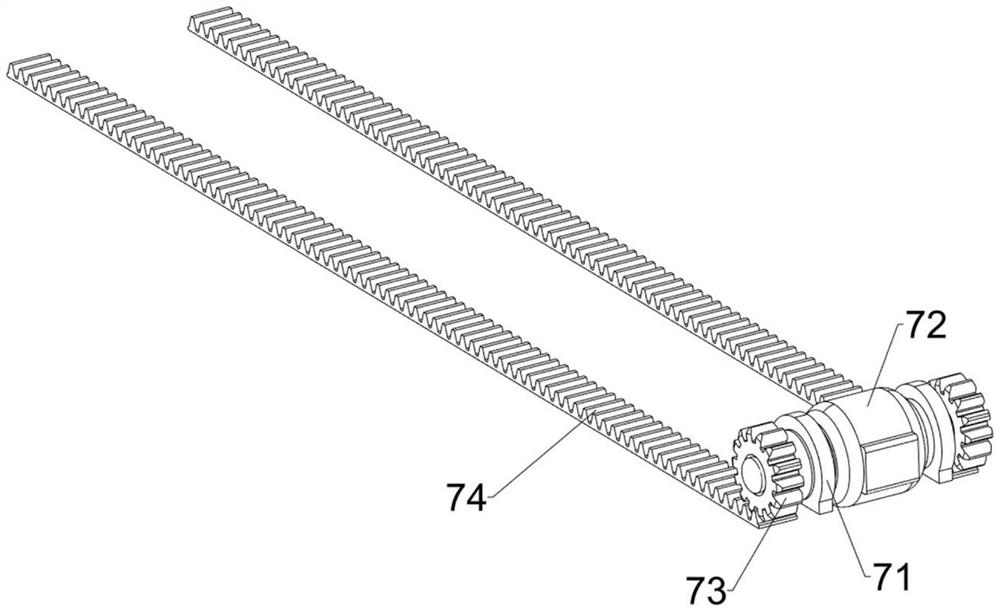

[0029] The reciprocating mechanism 7 includes a connecting frame...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 5-9As shown, a pusher mechanism 9 is also included, and the pusher mechanism 9 includes a trigger lever 91, a sliding frame 92, a positioning block 93, a first fixed seat 94, a first return spring 95, a second rack 96, a second gear 97. Transmission shaft 98, fixed ring sleeve 99, one-way clutch 910, third gear 911, third rack 912, push plate 913, guide frame 914, second guide rail frame 915 and handle ring 916, first mounting frame 4 The left side is provided with a trigger lever 91, and the left front side of the first guide rail frame 3 is provided with a positioning block 93, and the positioning block 93 is slidably connected with a sliding frame 92, and the rear side of the sliding frame 92 is provided with a second rack 96, and the first guide rail The lower part of the left front side of the frame 3 is provided with a first fixed seat 94, the first return spring 95 is connected between the left side of the first fixed se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com