One-step furnace continuous production method and device for sub/hypereutectic γ-titanium-aluminum-vanadium alloy

A technology of titanium-aluminum-vanadium alloy and production method, which is applied in the field of continuous production method and device in one-step furnace of sub/hypereutectic γ-titanium-aluminum-vanadium alloy, and can solve the problems of easy explosion, high energy consumption, insufficient cooling capacity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

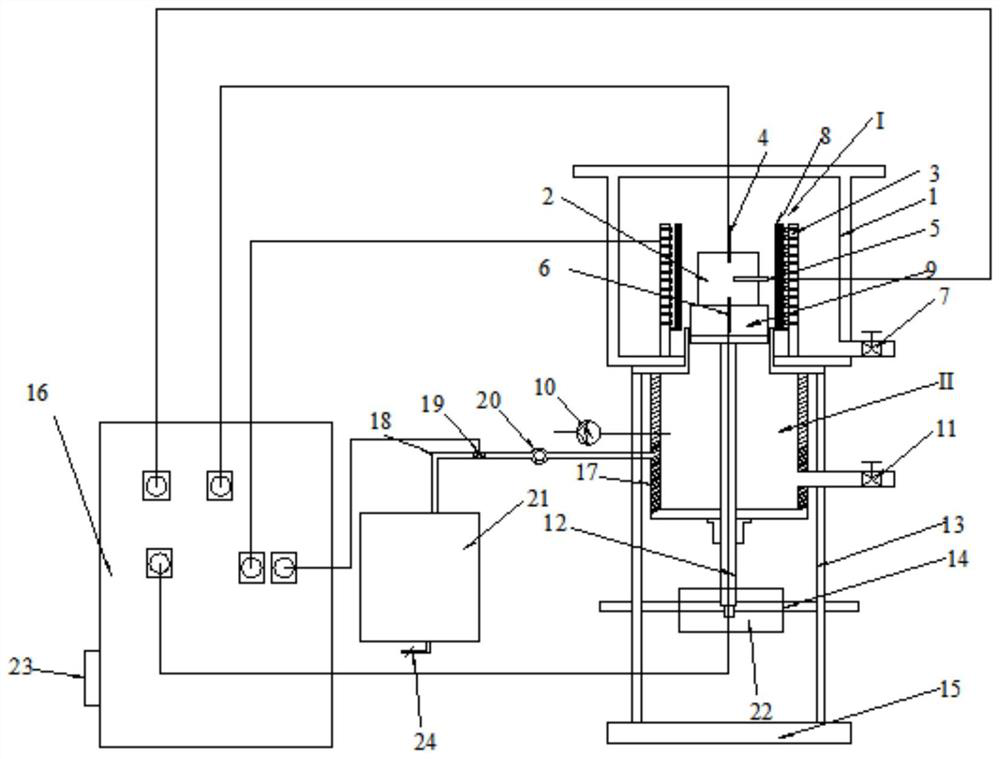

[0048] A continuous production device in a one-step furnace for hypo / hypereutectic γ-titanium-aluminum-vanadium alloy, the schematic diagram of which is shown in figure 1 , divided into heating reaction zone I, cooling zone II and transmission system, wherein, heating reaction zone I includes heating reaction zone furnace body 1, induction coil 3, graphite heating element 8, upper thermocouple 4, middle thermocouple 5, multifunctional Controller 16; the furnace body in the heating reaction zone forms a heating chamber, an induction coil 3 is arranged in the heating chamber, a graphite heating element 8 is arranged in the induction coil 3, and two thermocouples are arranged in the heating chamber , thermocouple 4 is used to detect the temperature of the upper surface of the reactor; the middle thermocouple 5 is used to detect the temperature of the center of the heating reaction zone; The system platform movement is always in contact with the lower surface of the reactor. The ...

Embodiment 2

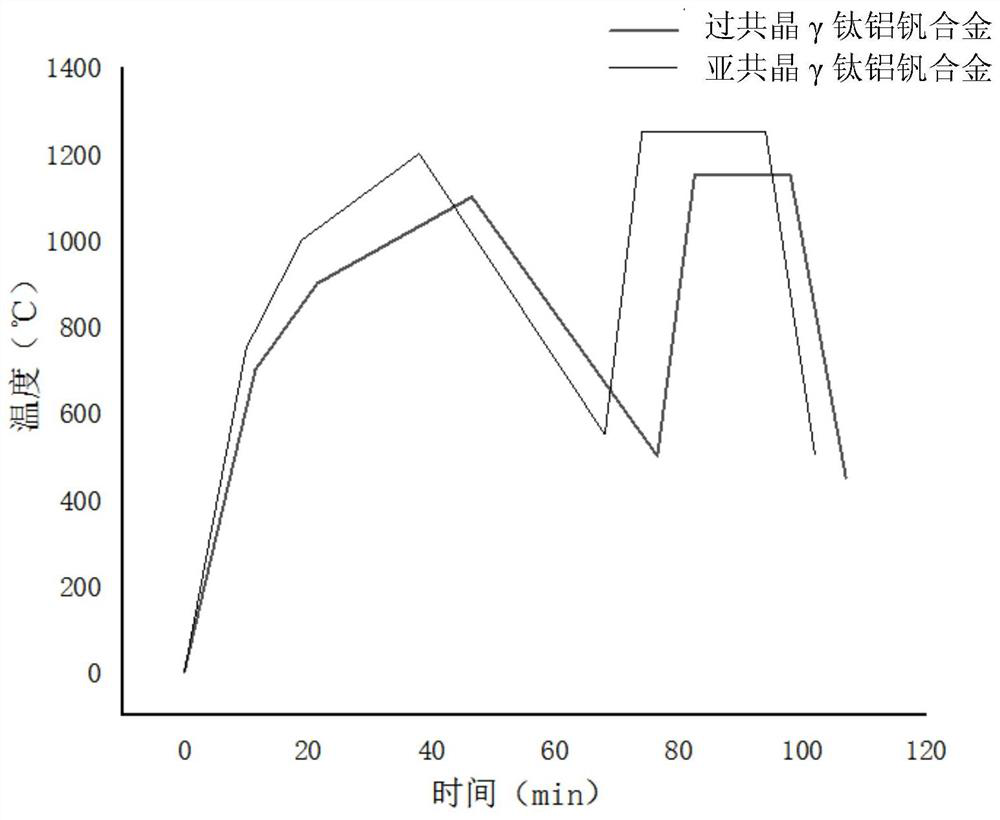

[0066] In this example, a hypoeutectic γ-titanium-aluminum-vanadium alloy with a diameter of 50 mm and a thickness of 1 cm is produced in a cylindrical shape of Ф50 aluminum with an atomic percent content of 48%.

[0067] The continuous production device in the one-step furnace for the hypo / hypereutectic γ-titanium-aluminum-vanadium alloy is the same as that in Example 1.

[0068] A continuous production method in a one-step furnace for hypo / hypereutectic γ-titanium-aluminum-vanadium alloy, specifically comprising the following steps:

[0069] (1) Material preparation before experiment:

[0070]The mass ratio of materials for producing Ф50 hypoeutectic γ-titanium-aluminum-vanadium alloy is: titanium sponge: Al powder: slagging agent: oxidation reaction heating agent: V particles = 48:62:16:62:7. The oxidation reaction exothermic agent that present embodiment adopts is NaClO 4 , The slagging agent is CaO.

[0071] (2) vacuuming

[0072] Dry and mix the raw materials and add...

Embodiment 3

[0083] In this embodiment, a hypereutectic γ-titanium-aluminum-vanadium alloy with a diameter of 50 mm and a thickness of 1 cm is produced, with a cylindrical Ф50 aluminum content of 56 atomic percent.

[0084] The continuous production device in the one-step furnace for the hypo / hypereutectic γ-titanium-aluminum-vanadium alloy is the same as that in Example 1.

[0085] A continuous production method in a one-step furnace for hypo / hypereutectic γ-titanium-aluminum-vanadium alloy, specifically comprising the following steps:

[0086] (1) Material preparation before experiment:

[0087] To produce Ф50 hypereutectic γ-titanium-aluminum-vanadium alloy, the mass ratio is: titanium sponge: Al powder: slagging agent: oxidation reaction heating agent: V particles = 48:66:18:59:9. The oxidation reaction exothermic agent that present embodiment adopts is NaClO 4 , The slagging agent is CaO.

[0088] (2) vacuuming

[0089] Dry and mix the raw materials and add them to the crucible, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com