Process and system suitable for treating produced water with ultra-high salinity

A high salinity, produced water technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low oil recovery rate and excessive oily sludge by-product , poor quality and other problems, to achieve the effect of simple process and equipment operation, low oily sludge output, and high oil recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The object of this implementation treatment is the ultra-high salinity produced water of the No. 1 Union Station of Tahe Oilfield, which is the dehydration of the produced fluid from the carbonate reservoir after sedimentation. The salinity is 210,000mg / L, the density is 1.15kg / L, and the oil content is 1000mg / L; the proportion of floating oil is about 60%, the finely dispersed oil is about 20%, and the emulsified oil is about 20%. The density of the oil contained is 0.92kg / L ;Suspended solid about 500mg / L;Ca 2+ +Mg 2+ Content 13,000mg / L, total hardness 33,000mg / L; pH value 6.1.

[0034] Polyquaternium reversed demulsification and Q802 organic flocculant are all from Tianjin Zhengda Technology Co., Ltd. TS7652;

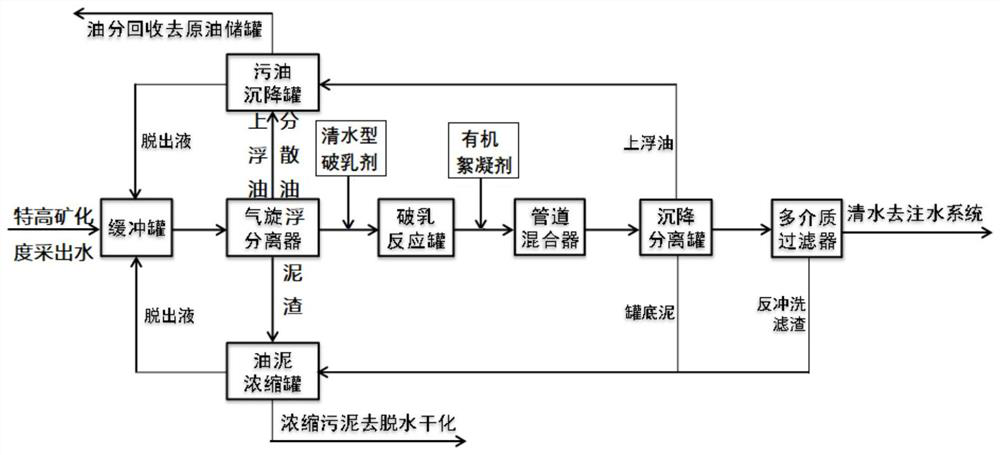

[0035] like figure 1 As shown in the figure, a process for the treatment of ultra-high salinity produced water in this embodiment includes the following process: the ultra-high salinity produced water first passes through the buffer tank to equalize, and is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com