Automatic stripping machine

A hemp peeling machine, fully automatic technology, applied in mechanical processing, fiber mechanical separation, textiles and paper making, etc., can solve the problems of difficult separation of hemp skin and hemp bone, achieve automatic control of production, solve the problem of difficult separation, stability enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

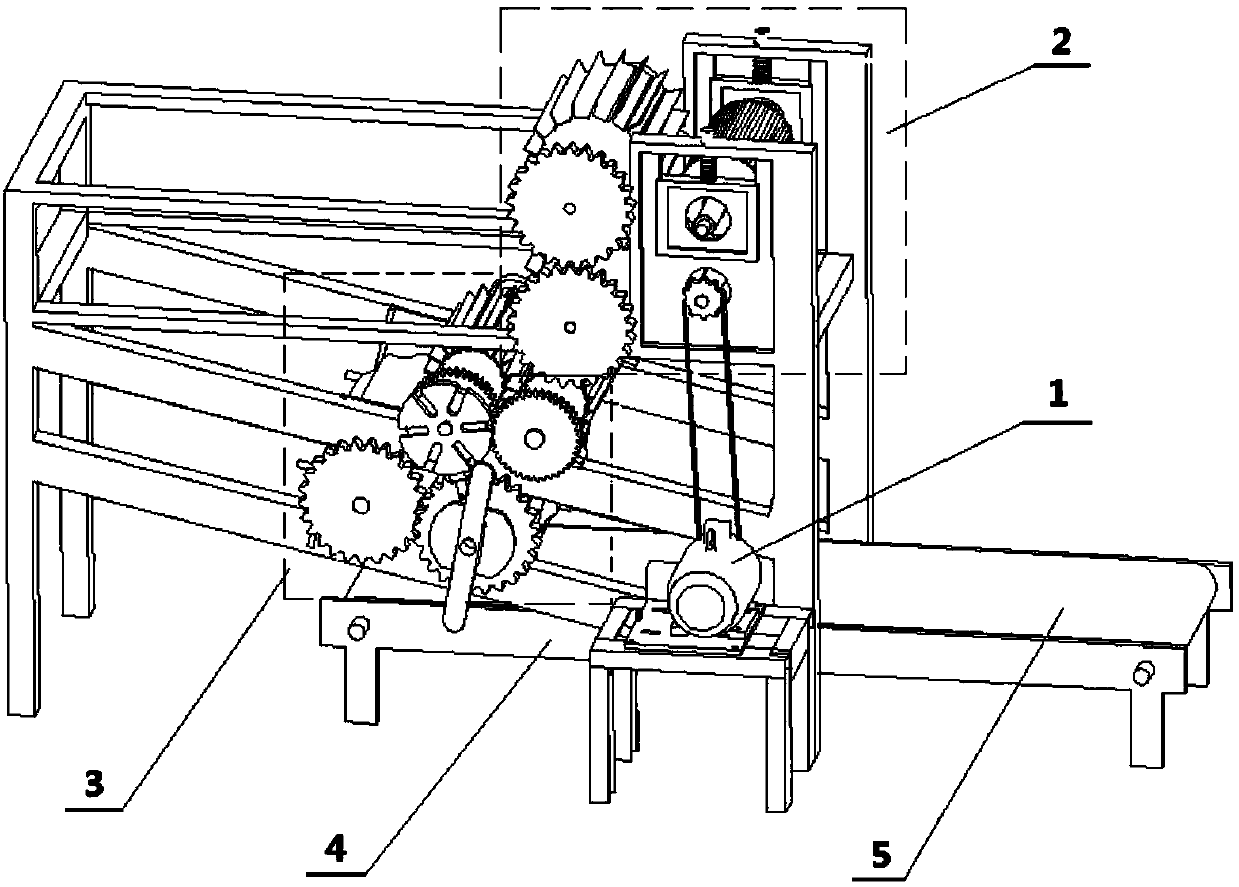

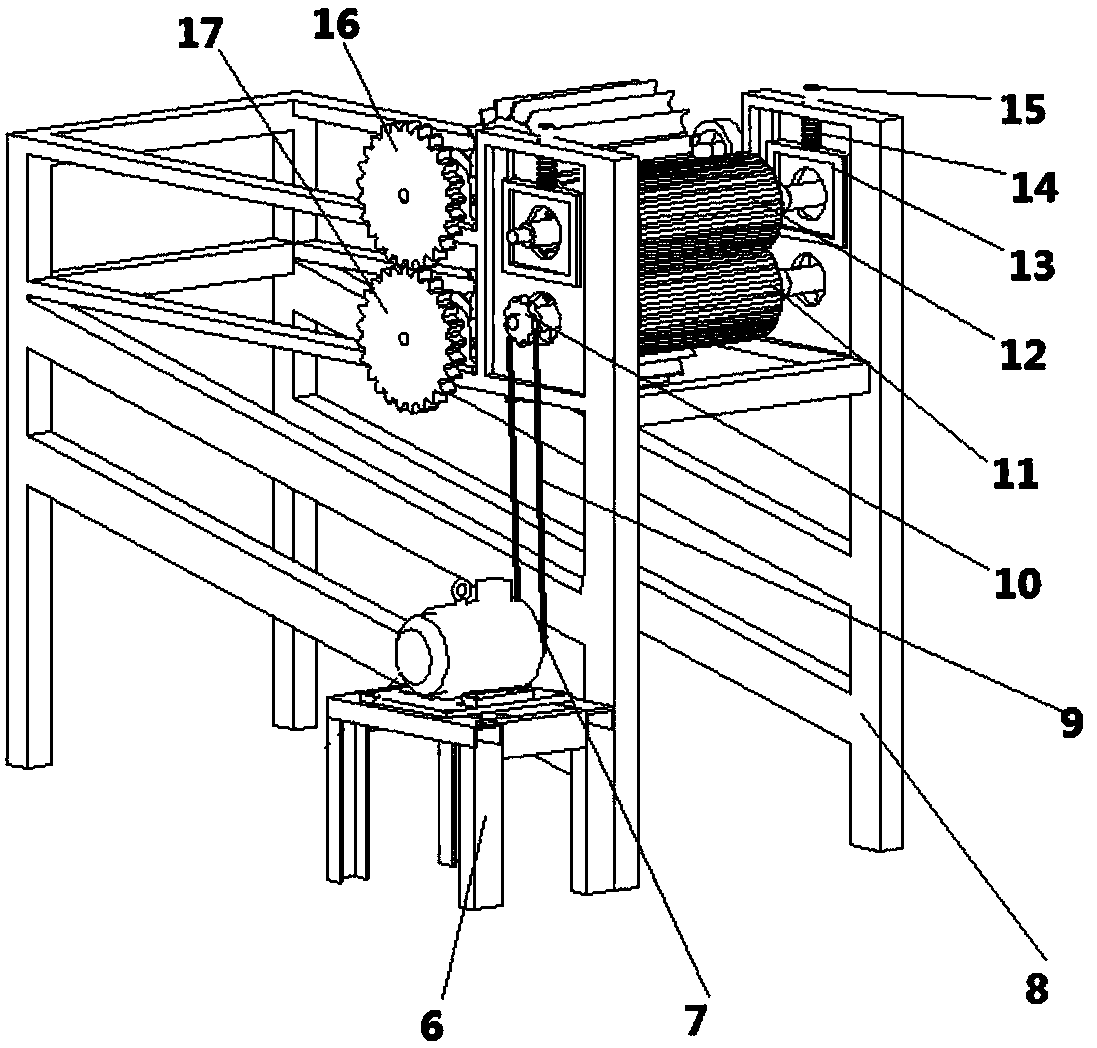

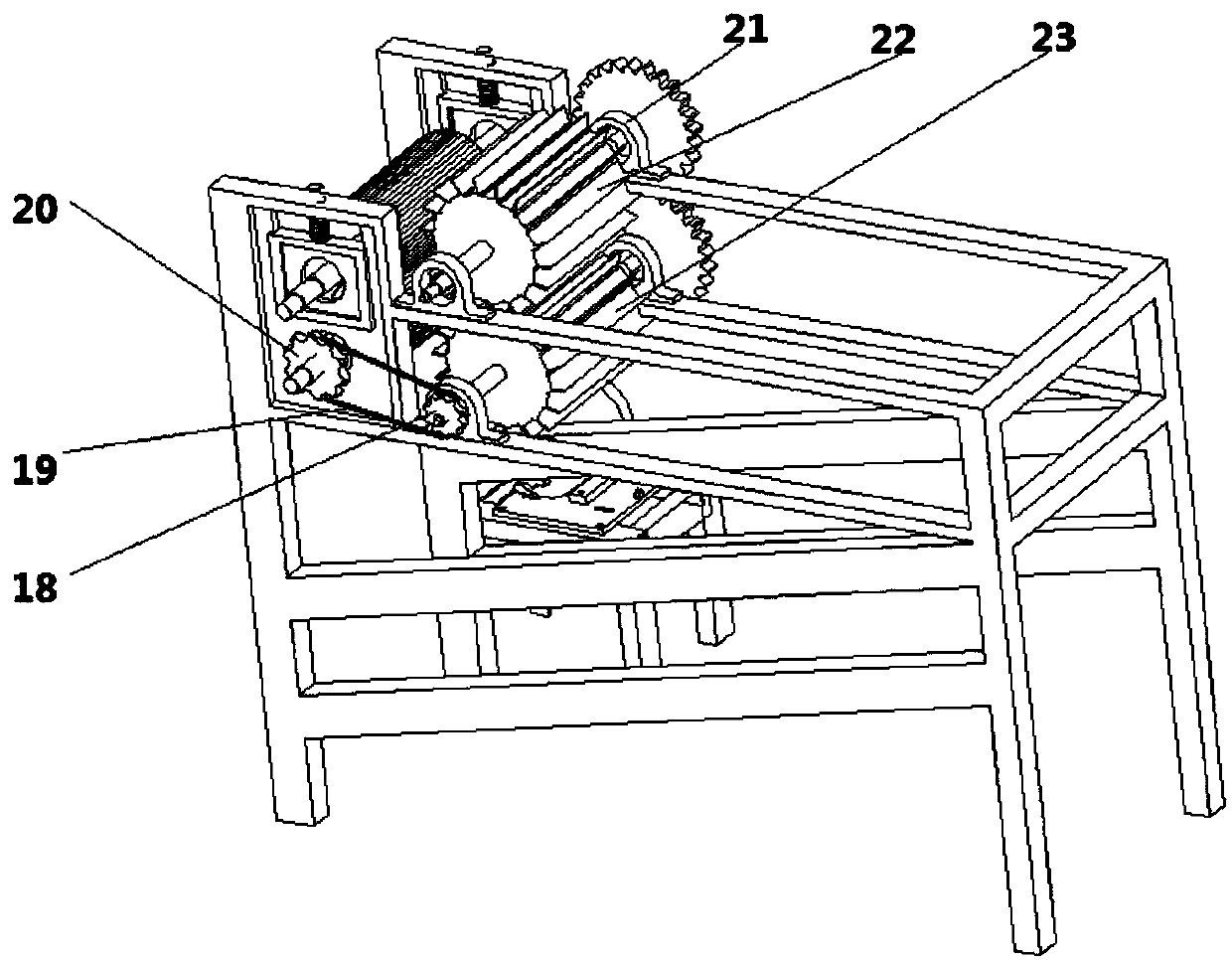

[0035] Such as figure 1 , figure 2 , image 3 Shown, the present invention comprises frame 8, power mechanism, hemp skin and hemp bone separation device and hemp skin output mechanism, and hemp skin and hemp bone separation device adopts speed difference separation device 2, intermittent type gear separation device 3; power mechanism Be placed next to frame 8, hemp skin output structure is positioned at frame 8 below, and speed difference separation device 2 is installed on the top of frame 8, and intermittent type shifting tooth separation device is installed in the middle part of frame 8.

[0036] The power mechanism is composed of a motor 1, a motor base 6, a first sprocket 7 and a first chain 9, the motor 1 is mounted on the motor base 6, the first sprocket is mounted on the motor 1, the first chain 9 and the first sprocket 7 with even.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com