A plug seeding gun for facility production

A technology of hole trays and facilities, which is applied in the direction of hole sowing seeders, sowers, and parts of seeders, can solve the problems that ordinary farmers and growers cannot accept, cannot control the sowing depth well, and it is difficult to ensure the consistency of seedling emergence, etc., to achieve Inexpensive, portable, and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

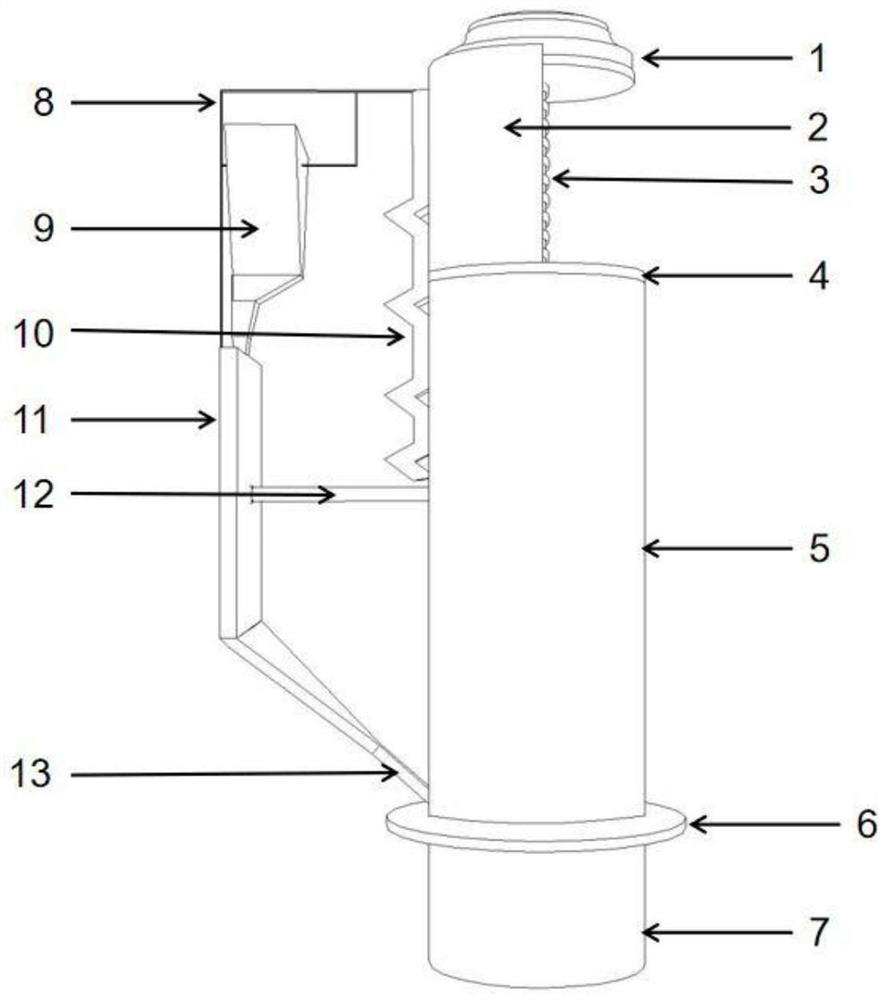

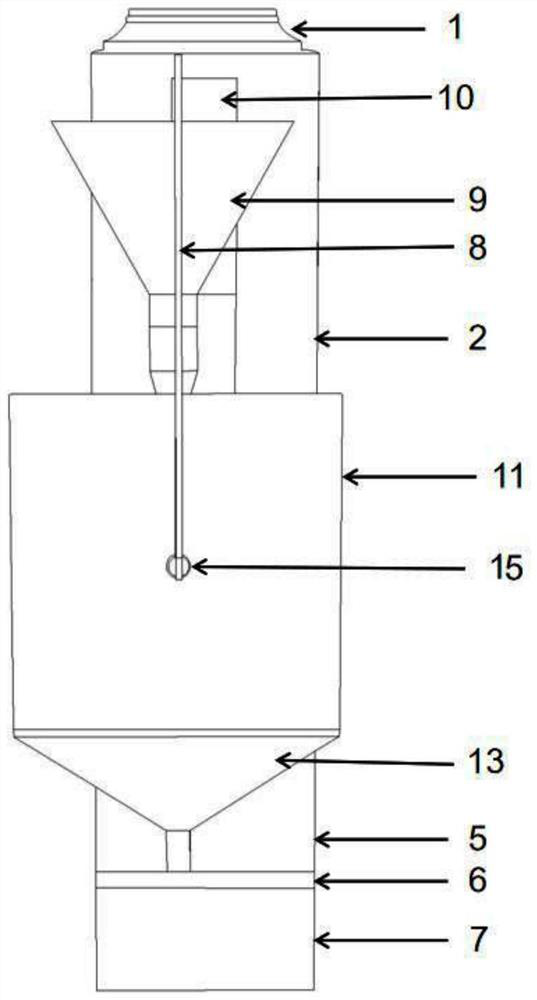

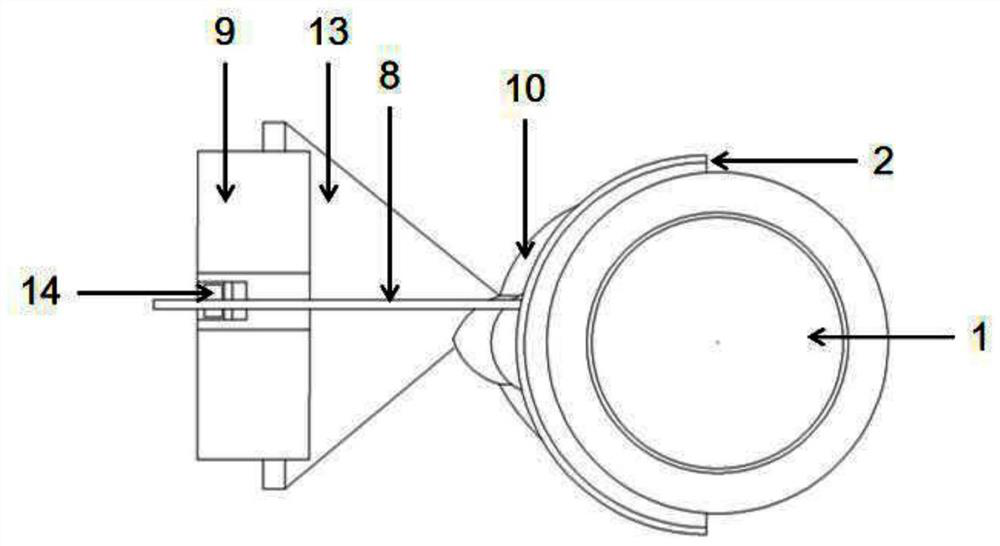

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as Figures 1 to 3 Shown, a kind of tray seeding gun that is used for facility production, it comprises sorting device and transmission device, and described sorting device comprises seed case 9, seed divider and seed chute 13, and described seed case 9 is used for Seeds to be sown are contained, the seed divider is located below the seed box 9, and the seed slide 13 is positioned below the seed divider, and the seed divider is used to transfer the seeds in the seed box 9 to the seed slide 13; the transmission device It includes a pressing transmission mechanism and a piston barrel 5. Below the piston barrel 5 is a seeding hole 7. A piston 19 is arranged inside the piston barrel 5. The piston 19 is connected to the pressing transmission mechanism. A limit card is provided around the upper end of the seeding hole 7. 6. The pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com