High-impact electroplating grade automotive pc/abs alloy material production equipment

A technology for alloy materials and production equipment, which is applied in metal processing and other directions to achieve the effects of simple structure, improved oil resistance and wear resistance, and improved impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of PC / ABS alloy material for high-impact electroplating grade vehicle, according to the number of parts by mass, including 40 parts of PC material, 30 parts of ABS material, 15 parts of high rubber powder, 5 parts of maleic anhydride grafted nitrile rubber, ma 10 parts of styrene-butadiene rubber grafted with anhydride, 1 part of antioxidant and 1 part of lubricant.

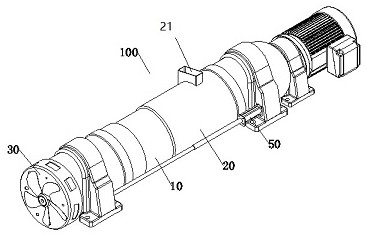

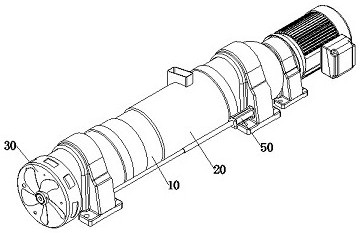

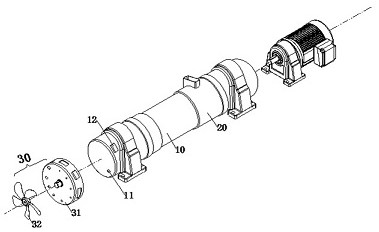

[0057] The preparation method of the above-mentioned high-impact electroplating grade automotive PC / ABS alloy material is also provided in this embodiment. The specific steps are: prepare materials according to the above components and parts by weight, and then graft 5 parts of maleic anhydride to nitrile rubber After fully stirring with 10 parts of maleic anhydride grafted styrene-butadiene rubber and 15 parts of ABS material, inject it into the screw granulator 100 at 180 ° C for screw extrusion granulation; then mix the particles with 40 parts of PC material, 15 parts 1 part of ABS material, 15 p...

Embodiment 2

[0065] A kind of PC / ABS alloy material for high-impact electroplating grade vehicle, according to the number of parts by mass, including 50 parts of PC material, 20 parts of ABS material, 20 parts of high rubber powder, 5 parts of maleic anhydride grafted nitrile rubber, ma 5 parts of styrene-butadiene rubber grafted with anhydride, 1 part of antioxidant and 0.5 part of lubricant.

[0066] The preparation method of the above-mentioned high-impact electroplating grade automotive PC / ABS alloy material is also provided in this embodiment. The specific steps are: prepare materials according to the above components and parts by weight, and then graft 5 parts of maleic anhydride to nitrile rubber After fully stirring with 5 parts of maleic anhydride grafted styrene-butadiene rubber and 10 parts of ABS materials, inject them into the screw granulator 100 at 230°C for screw extrusion granulation; then mix the particles with 50 parts of PC, 10 parts of ABS, 20 parts of high-grade rubbe...

Embodiment 3

[0074] A PC / ABS alloy material for high-impact electroplating grade vehicles, comprising 45 parts of PC material, 25 parts of ABS material, 10 parts of high rubber powder, 10 parts of maleic anhydride grafted nitrile rubber, 10 parts of styrene-butadiene rubber grafted with anhydride, 0.5 part of antioxidant and 0.1 part of lubricant.

[0075] The preparation method of the above-mentioned PC / ABS alloy material for high-impact electroplating grade vehicles is also provided in this embodiment. The specific steps are: prepare the materials according to the above components and parts by weight, and then graft 10 parts of maleic anhydride to nitrile rubber After fully stirring with 10 parts of maleic anhydride grafted styrene-butadiene rubber and 12.5 parts of ABS material, inject it into the screw granulator 100 at 240 ° C for screw extrusion granulation; then mix the particles with 45 parts of PC material, 12.5 parts 1 part of ABS material, 10 parts of high rubber powder, 0.5 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com