A low-temperature partial oxidation reforming system for fuel based on cold flame and its working method

A reforming system and working method technology, applied in the direction of combustion method, gas fuel burner, burner, etc., can solve the problems of easy extinguishment, unclearness, weak reactivity, etc., and achieve easy transportation and disassembly, and a compact overall structure , work safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

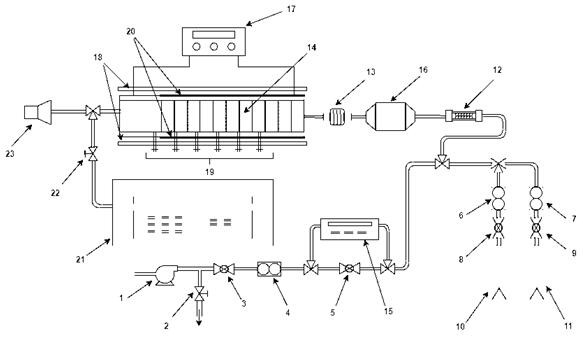

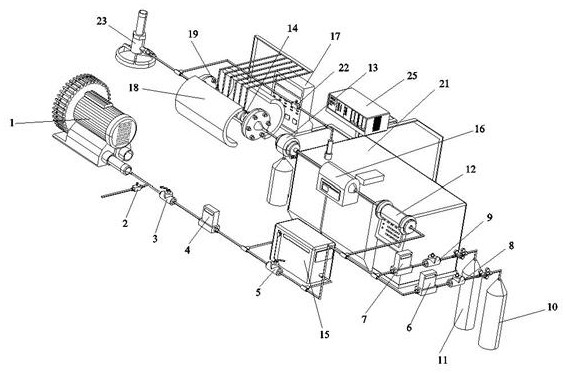

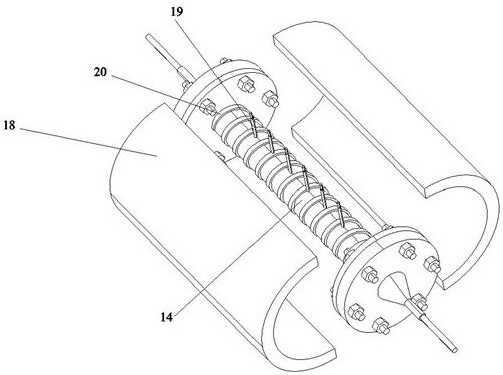

[0047] as attached figure 1 And attached figure 2 As shown, a fuel low temperature partial oxidation reforming system based on cold flame, including intake system, reaction system, data acquisition and temperature control system;

[0048] The air intake system is used to mix the fuel for the cold flame reforming reaction and input it into the reaction system;

[0049] The reaction system is used for the cold flame reforming reaction of fuel;

[0050] The data acquisition and temperature control system is used to control and display the reaction temperature of the reaction system, and detect the components of the reformed product after the reaction in the reaction system;

[0051] The air intake system also includes an ozone generator 15. The ozone generator 15 is used to output ozone into the fuel undergoing the cooling flame reforming reaction, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com