Frame structure unloading and column pulling structure and construction method thereof

A technology of frame structure and construction method, applied in the direction of building structure, building maintenance, construction, etc., to achieve the effect of facilitating the removal of the jack and ensuring the load strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

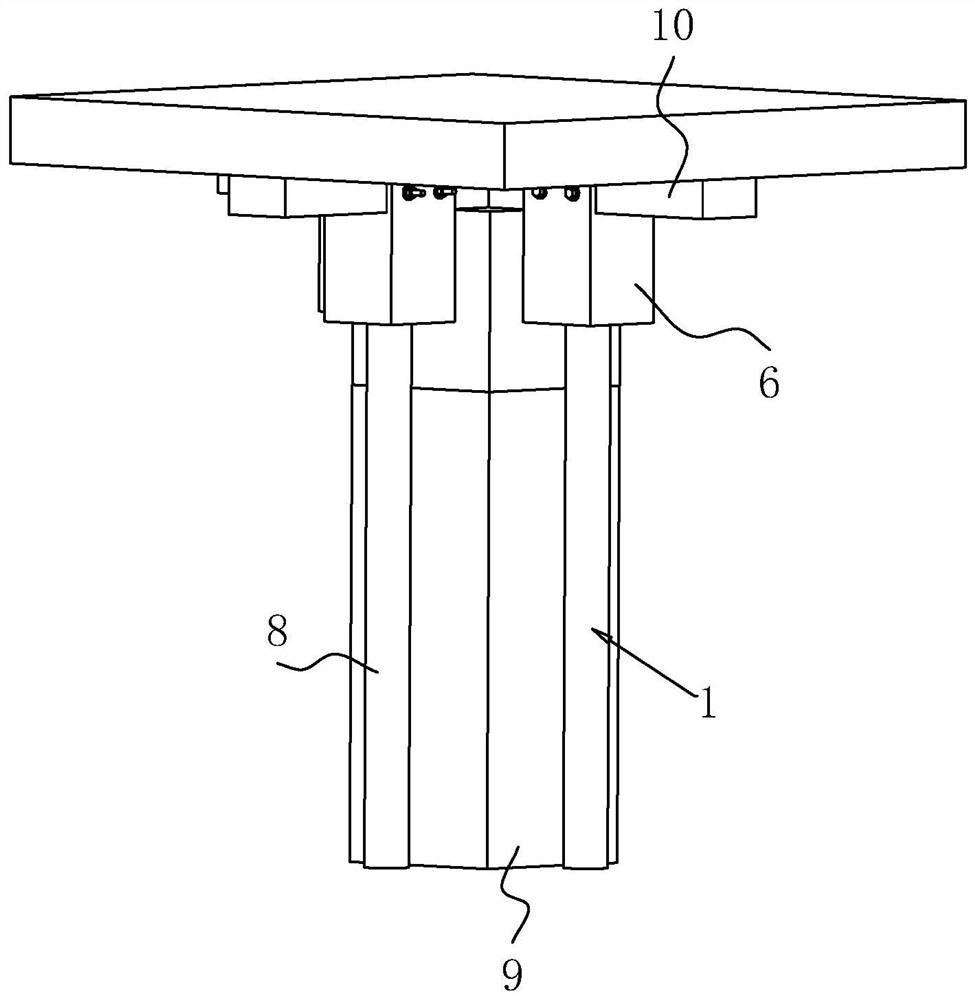

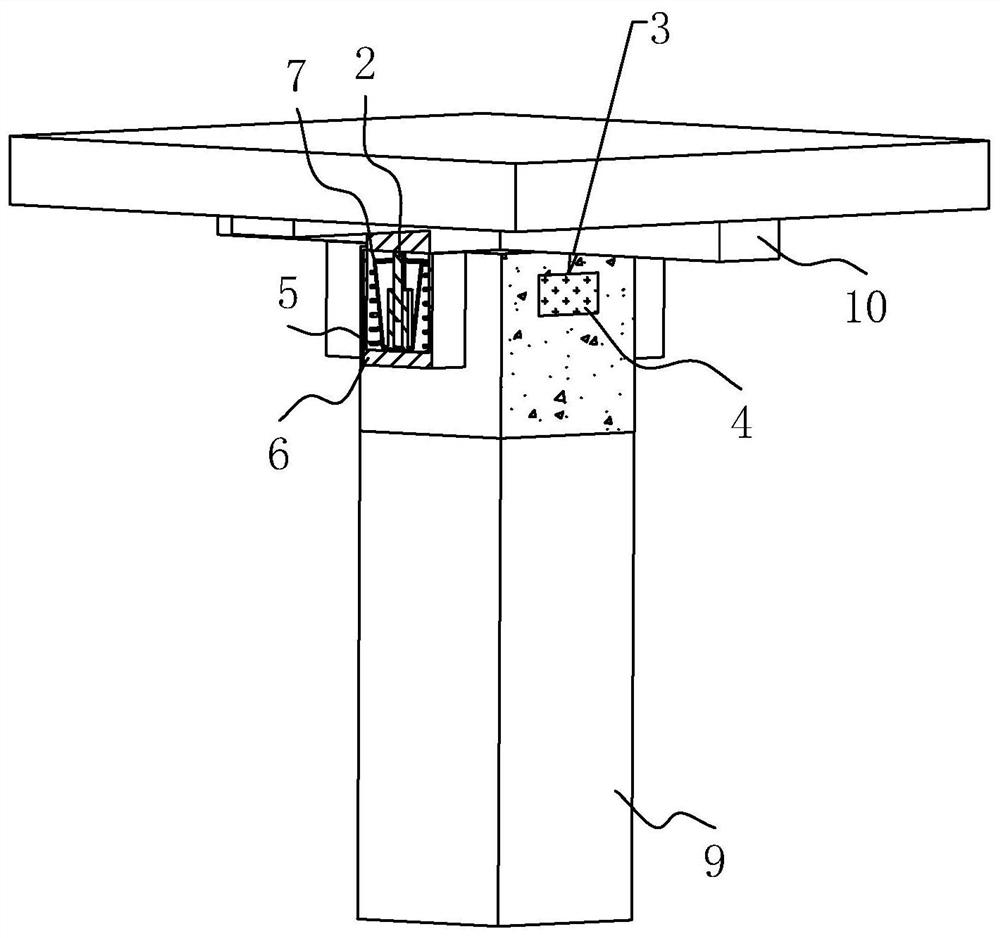

[0047] The embodiment of the present application discloses a frame structure unloading column pulling structure. refer to figure 1 , the frame structure unloading column structure includes three support bases 1 and the jack 2 installed on the support base 1, the support base 1 is composed of a steel support 8, the steel support 8 is placed on the ground, and the jack 2 is placed on the top of the steel support 8 Above, the output end of the jack 2 abuts against the original load-bearing beam 10, the position where the jack 2 abuts against the original load-bearing beam 10 is close to the original load-bearing column 9, and the three original load-bearing beams 10 around the original load-bearing column 9 are supported by the jack 2 The load-bearing effect of the original load-bearing column 9 on the original load-bearing beam 10 is realized under the action.

[0048] refer to figure 1 and figure 2, the original load-bearing column 9 on the side where the jack 2 is not set ...

Embodiment 2

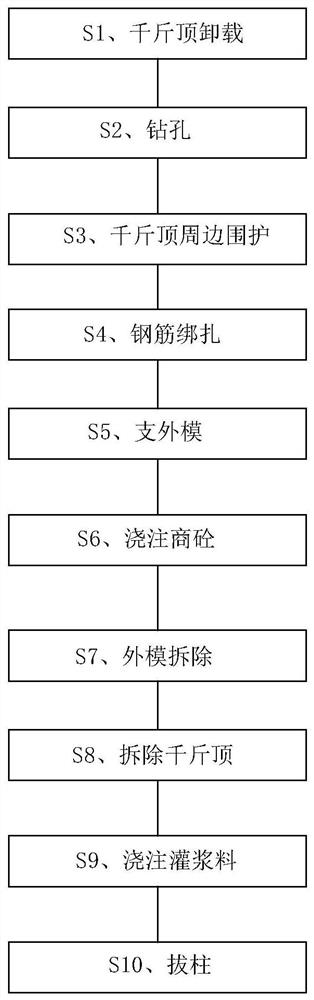

[0054] The embodiment of the present application discloses a construction method of a frame structure unloading column pulling structure. refer to image 3 , the construction method of frame structure unloading column structure includes the following steps,

[0055] S1. Jack 2 is unloaded, and a steel support platform 8 is built to form a support seat 1, which supports three points of two original load-bearing beams 10 around the original load-bearing column 9. -2t, the position where the jack 2 abuts against the original load-bearing beam 10 is close to the original load-bearing column 9, further ensuring the safe unloading work of the original load-bearing column 9 to the original load-bearing beam 10 after drilling;

[0056] S2, drilling, the original load-bearing column 9 is located at the lower part of the beam to carry out core drilling to form a through hole 3, the through hole 3 is set through, and the length direction of the through hole 3 is along the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com