Efficient sewage purification system

A technology for purifying system and sewage, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc. Improve sewage sedimentation effect, good cleaning effect, and ensure the effect of load intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

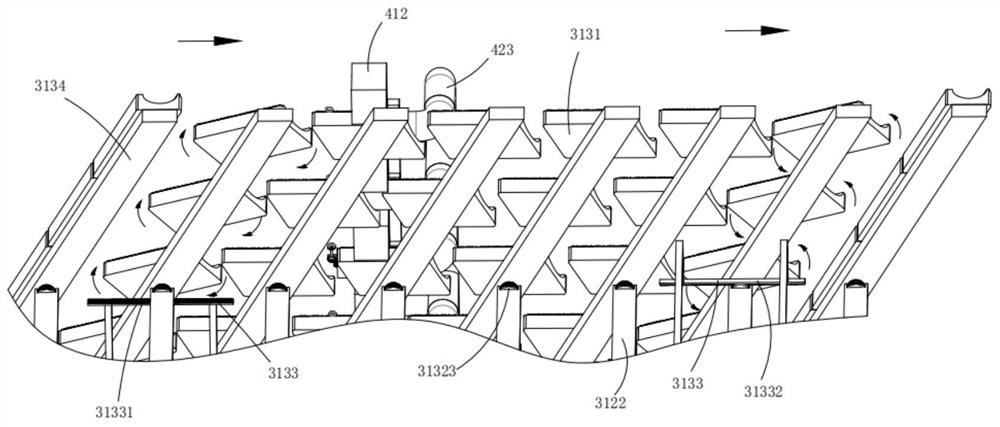

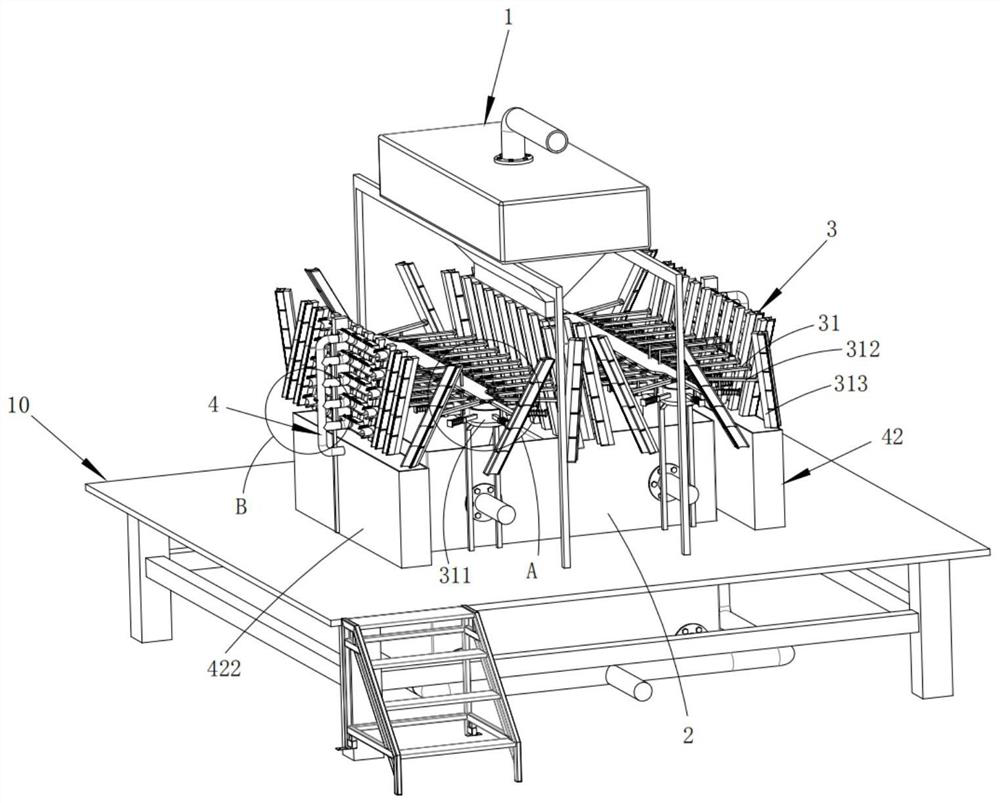

[0042] Such as Figure 3 to Figure 5 As shown, a sewage high-efficiency purification system includes a frame 10, a flocculation tank 1 and a sedimentation tank 2 arranged up and down, and a sewage flow channel 11 is formed between the flocculation tank 1 and the sedimentation tank 2. It is characterized in that it also includes:

[0043] A sedimentation device 3, the sedimentation device 3 includes a first-stage sedimentation mechanism 31 arranged between the flocculation tank 1 and the sedimentation tank 2 and installed in the sedimentation tank 2 and located at the end of the sewage flow channel 11 The second stage sedimentation mechanism 32;

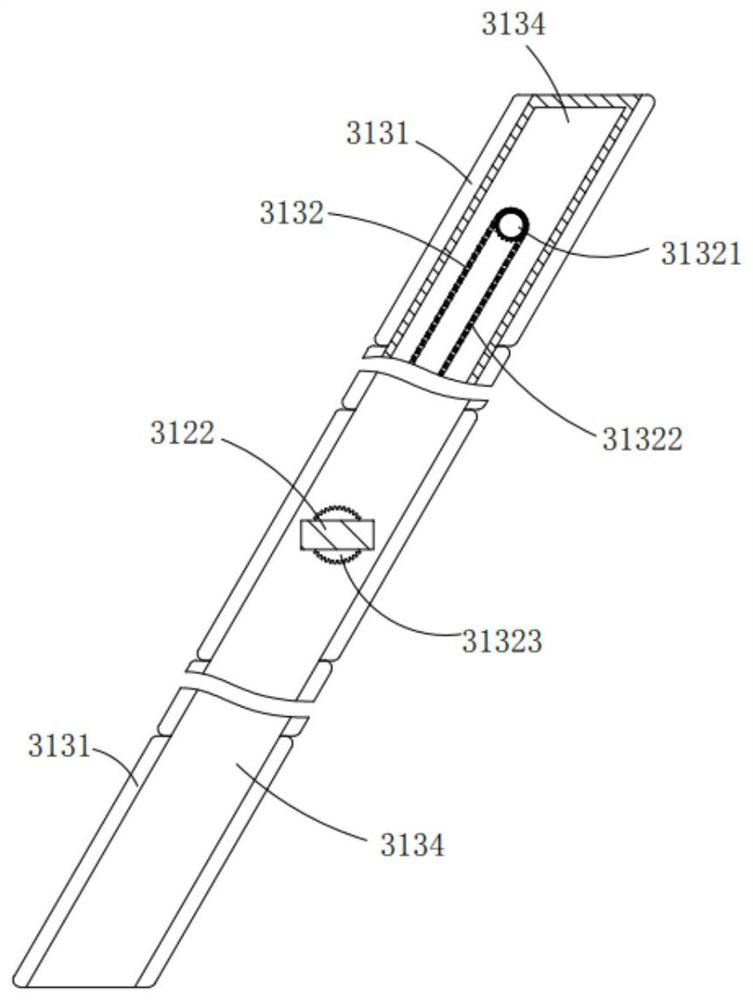

[0044]The first-stage sedimentation mechanism 31 includes two sets of rotary assemblies 311 symmetrically arranged on both sides of the sewage flow channel 11, several sets of push assemblies 312 arranged along the rotary paths of the two sets of rotary assemblies 311, and correspondingly installed on the two sets of rotary assemblies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com