Inclined plate and inclined pipe combined sewage treatment system and treatment process thereof

A sewage treatment system and combined technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc. problem, to achieve the effect of ingenious design, simple structure, and reducing attachments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

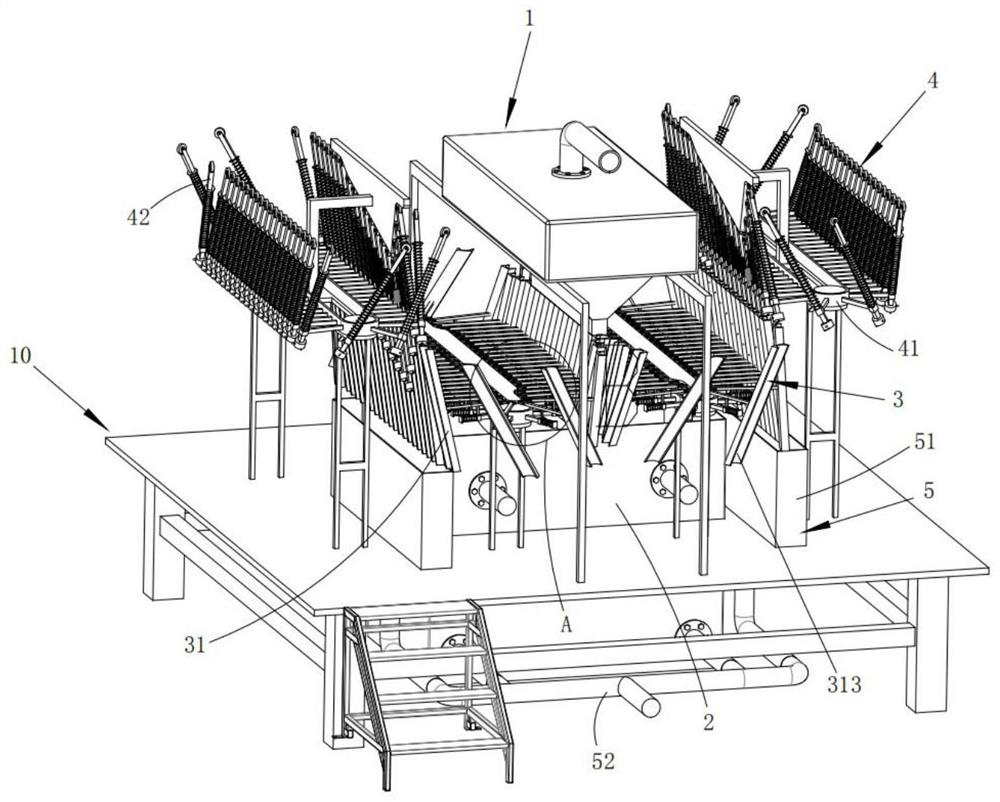

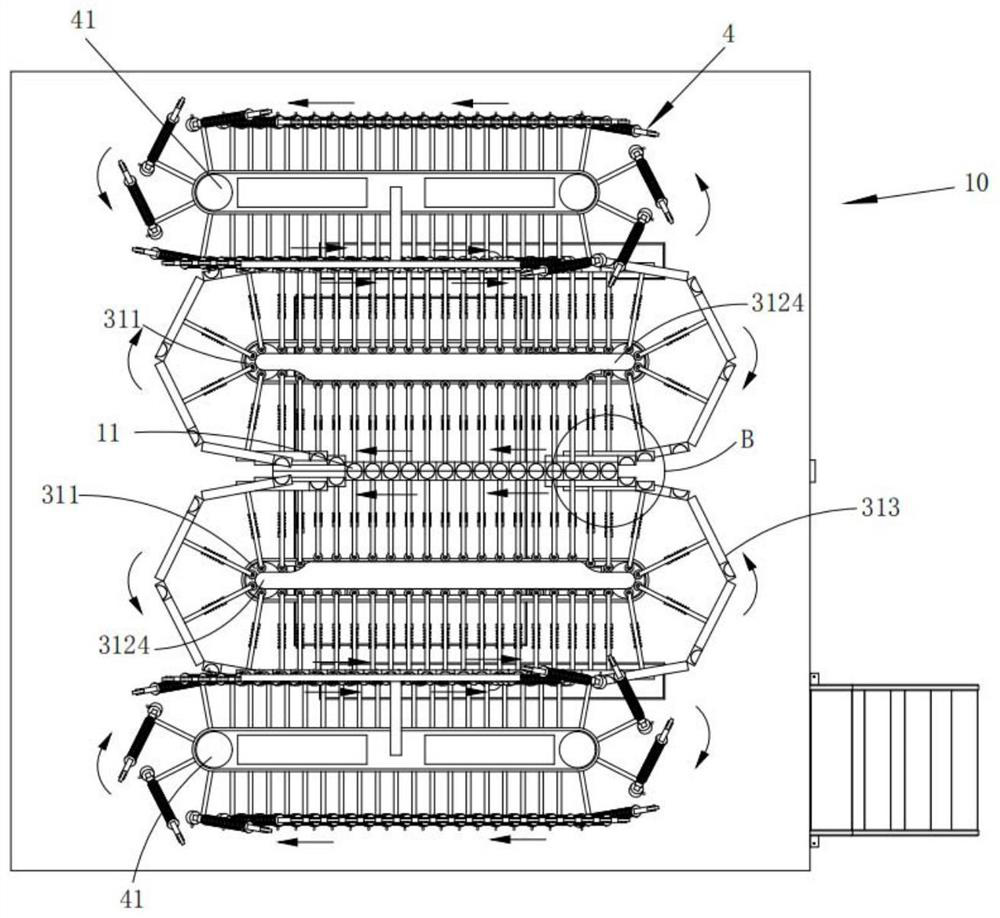

[0046] Such as figure 1 and figure 2 As shown, a combined sewage treatment system with inclined plates and inclined tubes includes a frame 10, a flocculation tank 1 and a sedimentation tank 2 arranged up and down, a sewage flow channel 11 is formed between the flocculation tank 1 and the sedimentation tank 2, and include:

[0047] A sedimentation device 3, the sedimentation device 3 includes an inclined tube sedimentation mechanism 31 arranged between the flocculation tank 1 and the sedimentation tank 2 and a settling mechanism installed in the sedimentation tank 2 and located at the end of the sewage flow channel 11 Inclined plate sedimentation mechanism 32;

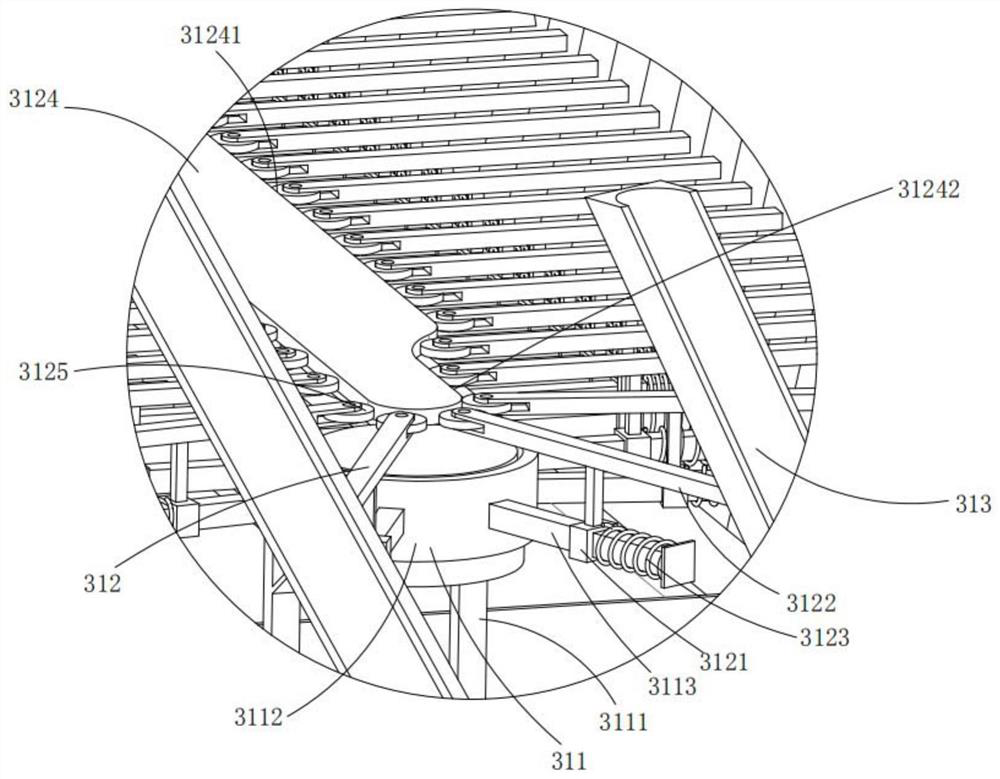

[0048] The inclined tube settling mechanism 31 includes two sets of rotary assemblies 311 symmetrically arranged on both sides of the sewage flow channel 11, two sets of pushing assemblies 312 correspondingly arranged in the two sets of rotating assemblies 311, and several push assemblies installed in the two sets of...

Embodiment 2

[0073] Such as Figure 11 As shown, a combined sewage treatment process with inclined plates and inclined tubes comprises the following steps:

[0074] Step 1: The inclined pipes are joined together. Two groups of rotary assemblies 31 respectively carry the segments 313 to rotate synchronously before entering the sewage flow channel 11. The push assembly 312 drives the segments 313 to move to the middle position, and the segments 313 on both sides are assembled. Synthetic inclined tube;

[0075] Step 2: Sewage sedimentation. After step 1, the segment 313 assembled into an inclined pipe enters the sewage flow channel 11, and the sewage is precipitated through the segment 313 and the inclined plate sedimentation mechanism 32 in turn, and the sediment is deposited in the sedimentation tank 2 accumulation at the bottom;

[0076] Step 3: Segment cleaning. After step 2, the segment 313 assembled into an inclined pipe leaves the sewage flow channel 313 and moves to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com