Tire bag type anti-slip hole packer for bottom-pumping roadway gas extraction drilling

A technology for gas extraction and anti-fall, which is applied in gas discharge, mining equipment, earth-moving drilling, etc. It can solve problems such as affecting the efficiency and effect of gas extraction, failure to insert hole sealers smoothly, and increasing the workload of workers. The effect of reducing labor workload, compact structure and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

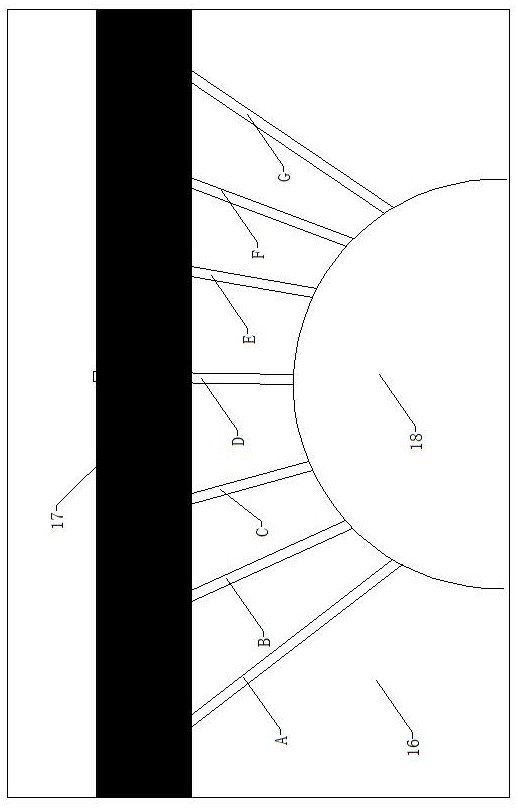

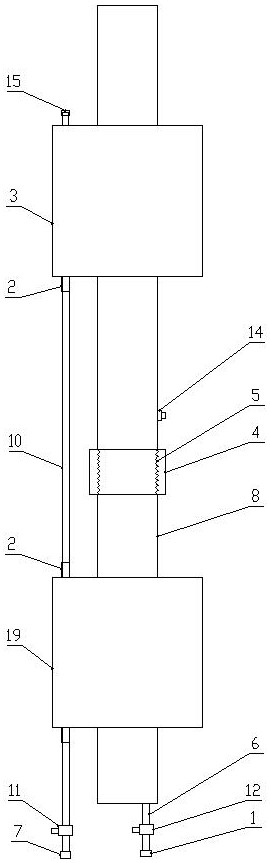

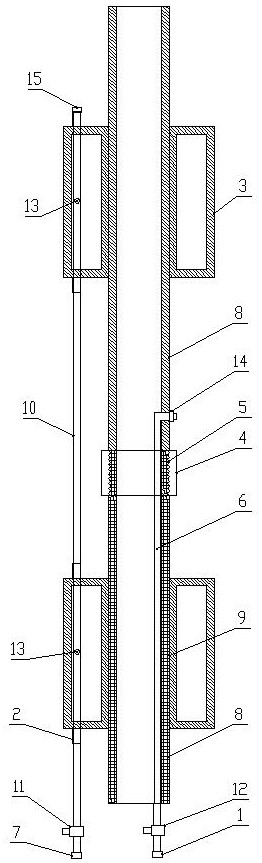

[0029] Such as Figure 1-3 As shown, the tire capsule type anti-slip hole sealing device for gas drainage drilling in bottom pumping roadways of the present invention includes a drainage pipe 8, a liquid injection pipe 10, a grouting pipe 6, an upper colloid tire capsule 3 and a lower colloid The fetal sac 19, the upper colloidal fetal sac 3 and the lower colloidal fetal sac 19 are arranged at intervals up and down, the upper colloidal fetal sac 3 is installed on the lower part of the extraction pipe 8 coaxially, and the lower colloidal fetal sac 19 is coaxially installed on the extraction pipe 8 In the upper part, the extraction pipe 8, the liquid injection pipe 10 and the grouting pipe 6 are all arranged in parallel, the liquid injection pipe 10 passes through the lower colloid fetal sac 19 and the upper colloid fetal sac 3, and the upper port of the liquid injection pipe 10 is provided with a plug 15 , the liquid injection pipe 10 is provided with a liquid outlet 13 inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com