Metal hydride hydrogen storage tank

A technology of hydrides and hydrogen storage tanks, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, fluid treatment, etc., can solve problems such as poor thermal management of hydrogen storage tanks, and achieve improved thermal management efficiency, Fix underperforming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

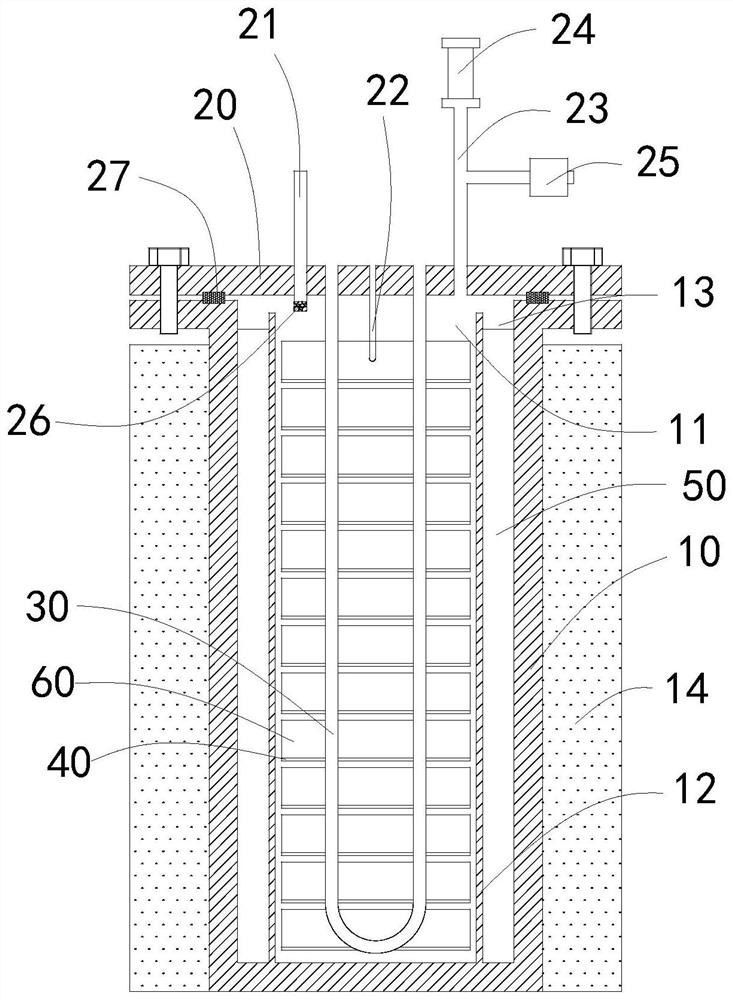

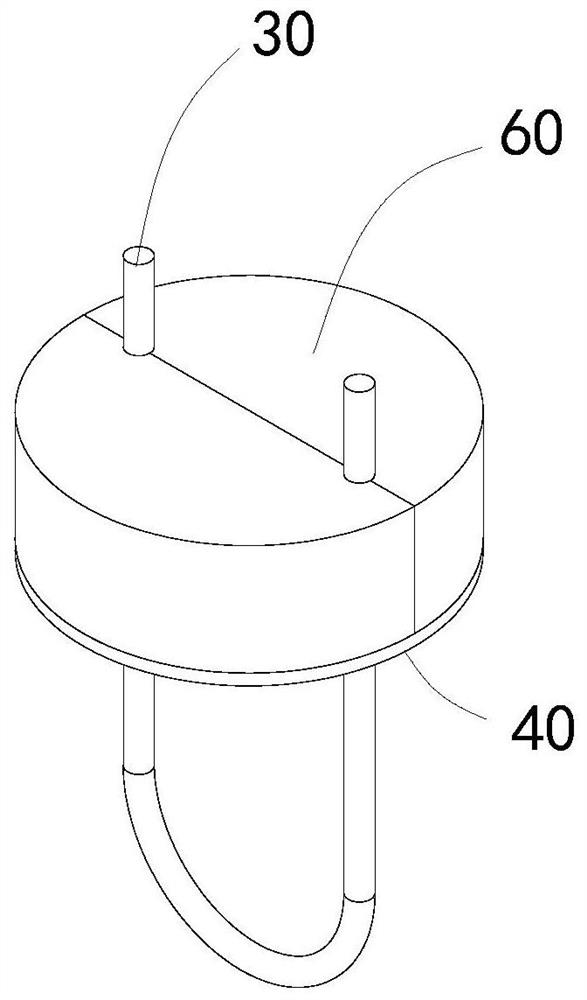

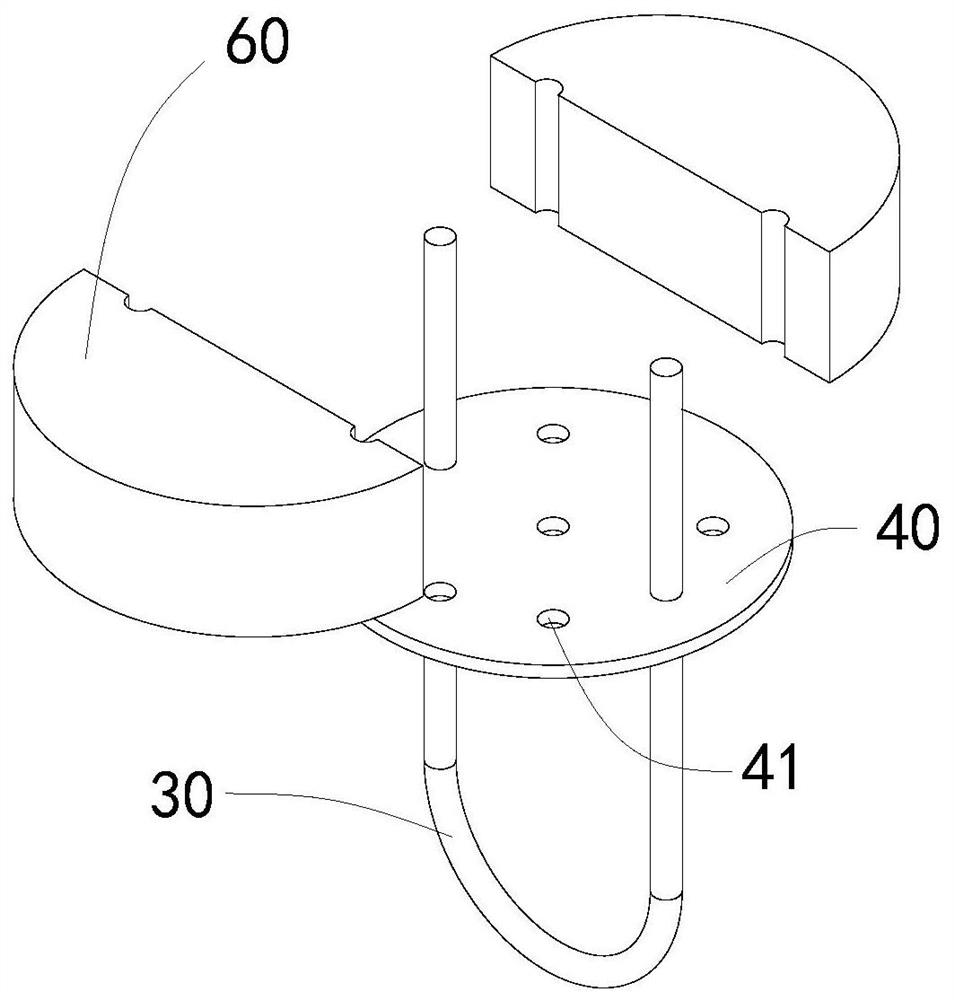

[0033] The invention provides a metal hydride hydrogen storage tank, the embodiment of which is as follows Figure 1 to Figure 3 As shown, it includes a tank body 10, a flange cover 20, a heat exchange tube 30 and a cooling fin 40; a storage chamber 11 is provided inside the tank body 10, and a storage chamber 12 is provided in the side wall of the storage chamber 11; Filled with a composite phase change material 50; the flange cover 20 is sealed and connected to the port of the tank body 10, and the flange cover 20 is provided with a hydrogen gas inlet and outlet 21, which is connected to the storage chamber 11; the heat exchange tube 30 is located on In the storage chamber 11, the input end and the output end of the heat exchange tube 30 are connected to the outside of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com