A solid oxide fuel cell connector and stack

A solid oxide and fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of partial deformation and bending of the connecting body, no consideration of the thermal management of the stack, and irregular shape of the stack. , to achieve the effect of reducing temperature gradient, optimizing thermal management efficiency, and large battery area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

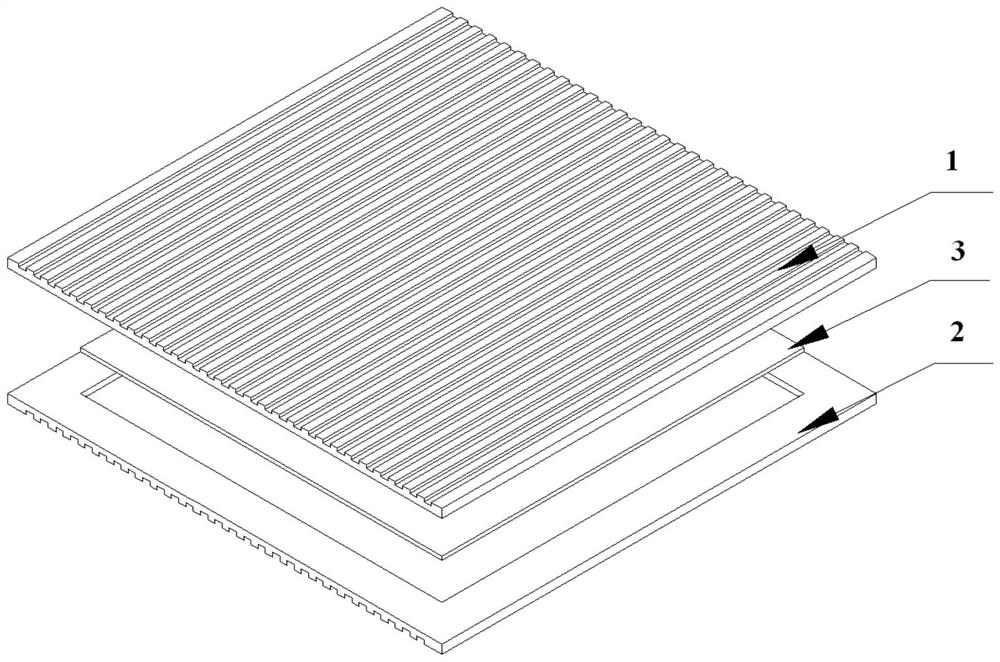

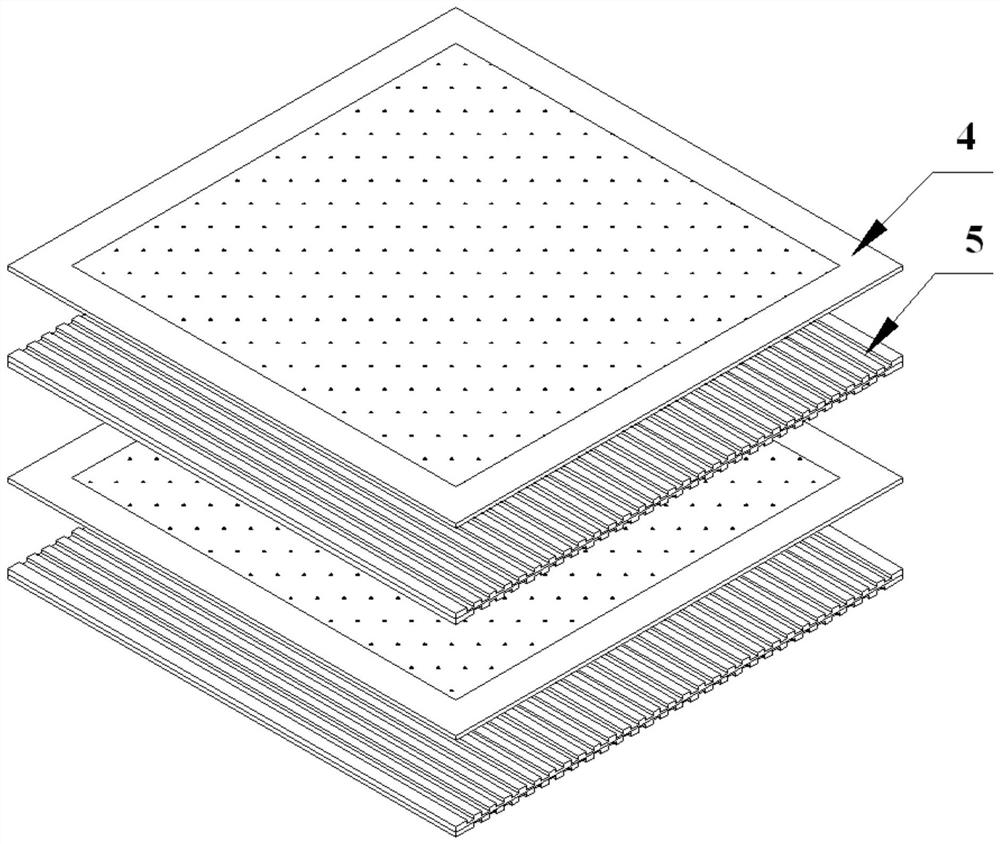

[0039] An embodiment of the solid oxide fuel cell connector of the present invention, the structural schematic diagram is shown in figure 1 .

[0040] The connected body in this embodiment includes a cathode plate 1, an anode plate 2 and a sealing intermediate layer arranged between the cathode plate and the anode plate. Both the cathode plate 1 and the anode plate 2 are provided with grooves for accommodating high-temperature heat pipes. The positions of the grooves on the cathode plate 1 and the anode plate 2 correspond to each other, and they are brazed together by vacuum. The positions of the grooves form a sealed center layer, the sealing middle layer is a hollow structure, and a high-temperature heat pipe is arranged in the sealing middle layer, and the high-temperature heat pipe includes a capillary core 3 and a working medium (not shown in the figure), and the capillary core is five layers of SUS310S stainless steel mesh, The pore diameter of the middle layer of stainle...

Embodiment 2

[0046] An embodiment of the connection body of the solid oxide fuel cell in the present invention, the connection body in this embodiment includes a cathode plate, an anode plate and a sealing intermediate layer arranged between the cathode plate and the anode plate. Both the cathode plate and the anode plate are provided with grooves for accommodating high-temperature heat pipes. The positions of the grooves on the cathode plate and the anode plate correspond to each other, and they are brazed together by vacuum. The positions of the grooves form a sealed intermediate layer, which seals the middle The layer is a hollow structure, and a high-temperature heat pipe is arranged in the sealed middle layer, and the high-temperature heat pipe includes a capillary core and a working medium, and the capillary core is nickel foam with a pore diameter of less than 0.1mm and a porosity greater than 95%. The working medium is 99.99% sodium metal, filled in a vacuum environment. The fillin...

Embodiment 3

[0052] An embodiment of the connection body of the solid oxide fuel cell in the present invention, the connection body in this embodiment includes a cathode plate, an anode plate and a sealing intermediate layer arranged between the cathode plate and the anode plate. Both the cathode plate and the anode plate are provided with grooves for accommodating high-temperature heat pipes. The positions of the grooves on the cathode plate and the anode plate correspond to each other, and they are brazed together by vacuum. The positions of the grooves form a sealed intermediate layer, which seals the middle The layer is a hollow structure, and the sealed middle layer is provided with a high-temperature heat pipe. The high-temperature heat pipe includes a capillary core and a working medium. The capillary core is a five-layer SUS310S stainless steel mesh, and the pore diameter of the stainless steel mesh in the middle layer is 10-50 mesh. Stainless steel mesh, the aperture of the remaini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com