Microbead immersed liquid laser and thermal management method thereof

A microbead immersion and laser technology, applied in laser parts, laser cooling devices, etc., can solve problems such as high-energy damage of working medium and inability to effectively solve thermal efficiency, etc., so as to improve optical performance, improve thermal management efficiency, and improve laser Effects of output power and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

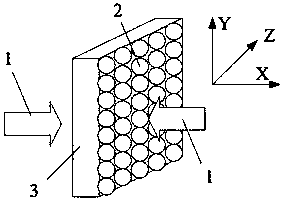

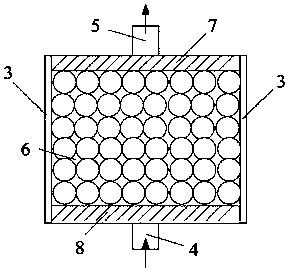

[0022] Principle of the present invention is as follows:

[0023] The solid laser gain medium with excellent laser performance is optically processed to obtain microbeads, and the microbeads are fixed in the fluorescent flow cell. The refractive index matching liquid flows between the microbeads and the four walls of the fluorescent flow cell, and the gain is affected by the circulating flow of the matching liquid. The direct cooling of the medium removes the waste heat generated during the pumping process, and finally realizes effective heat management during the working process of the laser.

[0024] The microbeads used in the present invention are glass or crystal materials, such as phosphate glass doped with rare earth ions or Re:YAG crystals, etc., which are optically processed into microbeads with a diameter of 1-40 mm.

[0025] The fluorescent flow cell used in the present invention is made of quartz or glass, and the four sides are light-transmitting windows. The flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com