Optical fiber connector and optical fiber connection structure

A fiber optic connector and connection cavity technology, applied in light guides, optics, instruments, etc., can solve the problems affecting the coupling accuracy of connectors and adapters, mechanical wear, etc., to ensure the transmission effect of optical fiber communication, prolong the service life, realize connection and Disconnected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

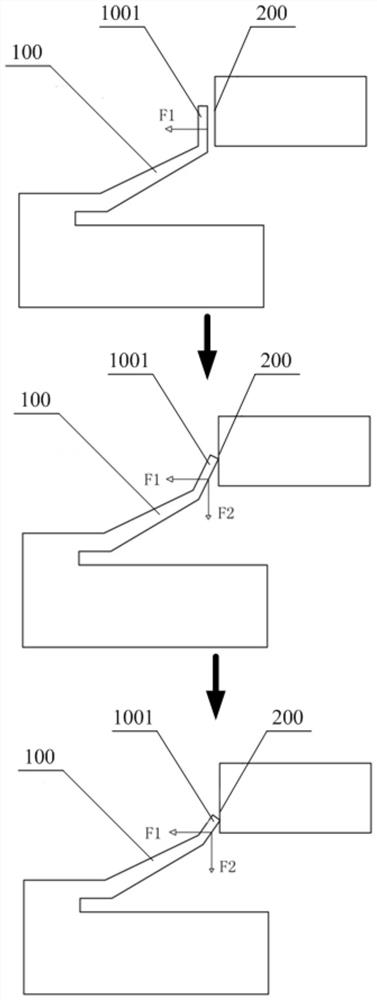

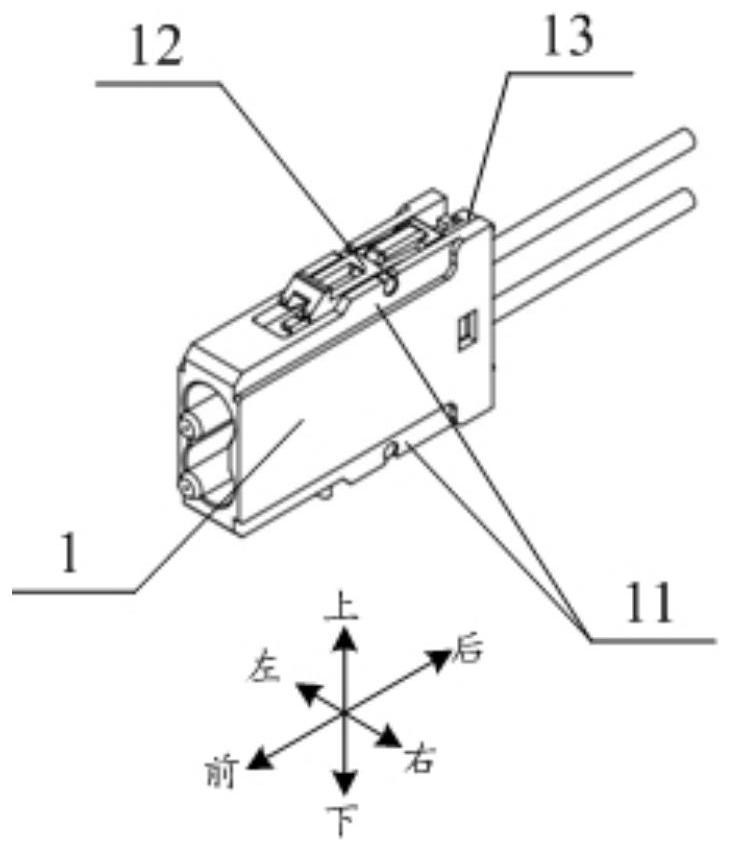

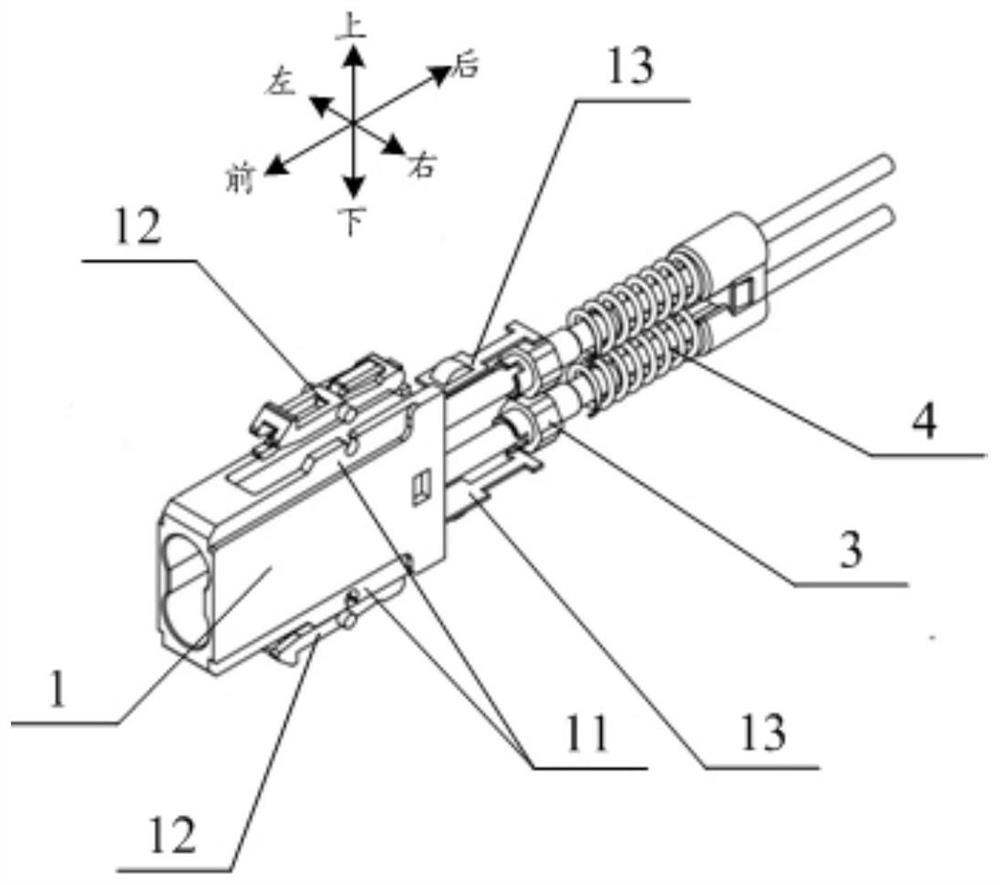

[0070] Such as Figure 2-15 As shown, the first optical fiber connector provided in this embodiment includes a connection housing 1 for plugging and mating with the adapter end connection cavity 2, and also includes an extension support body 11, a locking clip 12, and an elastic member. 124 and a latch height control member 13, wherein, the extension support body 11 is fixed on the outer surface of the connection housing 1, and a shaft hole 111 is opened on the outwardly extending end of the extension support body 11; The lock clip 12 includes a rotating shaft 121, a latch 122, and a stop portion 123, wherein the latch 122, the rotating shaft 121, and the stop portion 123 are sequentially arranged at intervals from front to back and sequentially fixed connection, the front-to-back direction is opposite to the inserting direction of the plug fit; the rotating shaft 121 is rotationally fitted in the shaft hole 111, and the latch 122 can be positioned in the shaft hole 111 Rotat...

Embodiment 2

[0089] Such as Figures 16-18 As shown, this embodiment provides a second optical fiber connector on the basis of the technical solution of the first embodiment, which differs from the technical solution of the first embodiment in that: the first limiting boss 132 The extraction surface 14 adopts another limited fit structure, and the second limit boss 133 and the insertion surface 15 adopt another limited fit structure; When the extension support body 11, the lock clip 12 and the latch height control member 13 are symmetrically arranged on the outer surfaces of opposite sides, the two symmetrically arranged latch heights are respectively connected through the hollow body 16. the tail of the control member 13, and make the two symmetrically arranged first limiting bosses 132 align with each other, and make the symmetrically arranged two said second limiting bosses 133 align or coincide with each other, so that the push-pull The hollow body 16 moves the two latch height contro...

Embodiment 3

[0092] Such as Figure 19-20 As shown, this embodiment provides a third optical fiber connector on the basis of the technical solution of the second embodiment, which is different from the technical solution of the second embodiment in that: one end of the cantilever structure is fixedly connected The bottom surface of the front part of the first space 112 , the other end of the cantilever structure is in contact with the middle bottom surface of the lock clip 12 , that is, the elastic member 124 is separated from the lock clip 12 . Therefore, through the above-mentioned structural design, the elastic member 124 can also have the ability to recover from deformation when it is in the squeezed state, so as to achieve the purpose of automatic reset in this embodiment.

[0093] The technical effect of this embodiment can be directly derived by referring to the technical effect of the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com