Production and manufacturing equipment of color film substrate and manufacturing method thereof

A technology for manufacturing equipment and color film substrates, applied in metal processing, nonlinear optics, instruments, etc., can solve the problems of inconvenient fixing, inconvenient use, and relative movement of substrates, and achieve convenient fixing and disassembly, convenient processing, and difficult displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

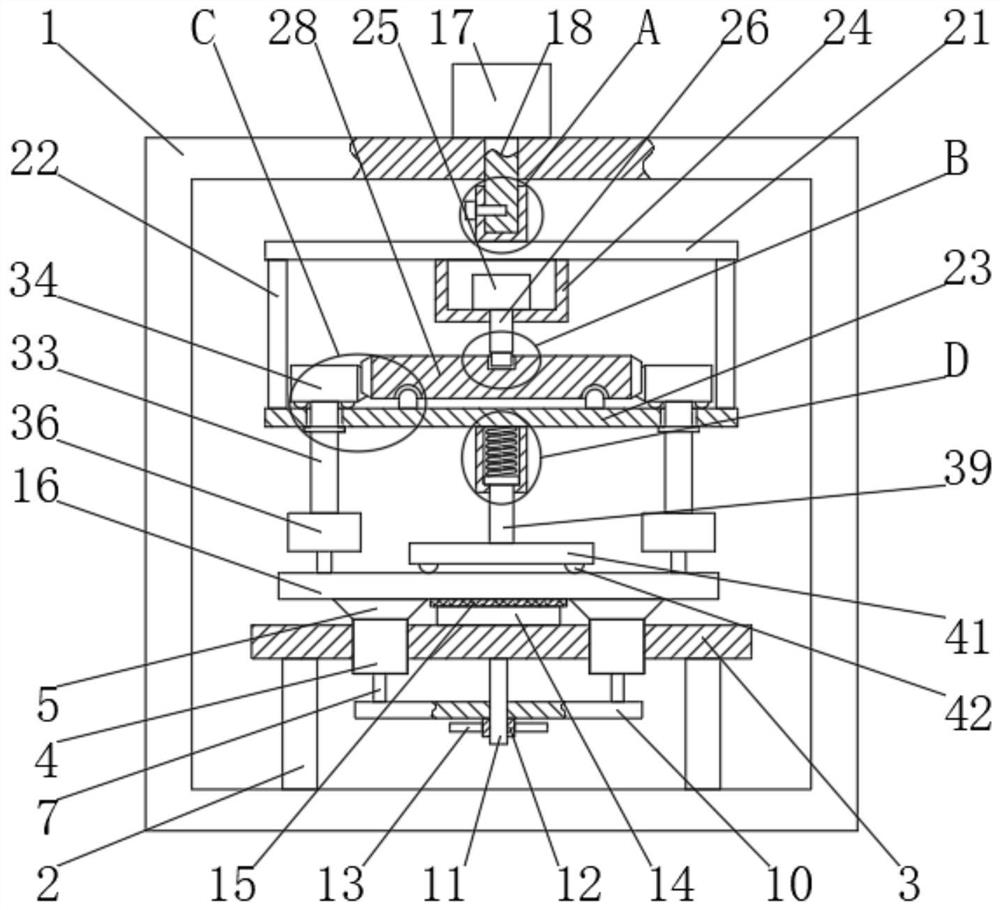

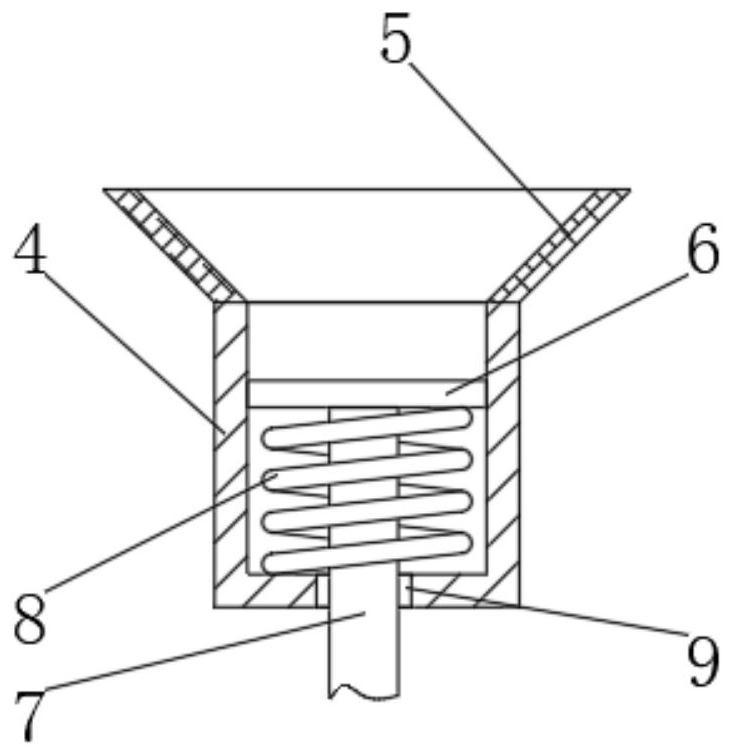

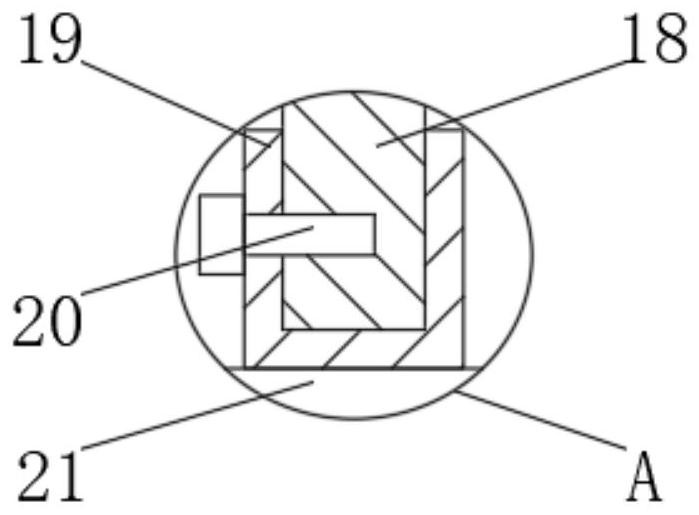

[0033] A production and manufacturing equipment for a color filter substrate, comprising a frame body 1, a leg 2 is welded on the inner side of the lower end of the frame body 1, and a workbench 3 is welded on the end of the leg 2 far away from the frame body 1, and the inside of the workbench 3 is The sealing cylinder 4 is fixedly sleeved, the upper end of the sealing cylinder 4 is provided with a suction cup 5, the substrate 16 is connected to the suction cup 5, the upper end of the frame body 1 is fixedly installed with a cylinder 17, and the lower end of the cylinder 17 A cylinder rod 18 is provided, and a cylinder rod 18 is slidably sleeved in the frame body 1, and a connecting sleeve 19 is sleeved on the outside of the end of the cylinder rod 18 away from the cylinder 17, and the end of the connecting sleeve 19 away from the cylinder 17 is welded with A top plate 21 , a suspender 22 is welded at the lower end of the top plate 21 , and a bottom plate 23 is welded at the en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap