Method for detecting luminous intensity and uniformity based on CCD perception

A detection method and luminous intensity technology, applied in 3D image processing, 3D modeling, image enhancement, etc., can solve problems such as fitting, not being able to adapt well to different display devices, and unable to achieve accurate detection of specific products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0049] A detection method of luminous intensity and uniformity based on CCD perception, comprising the following steps:

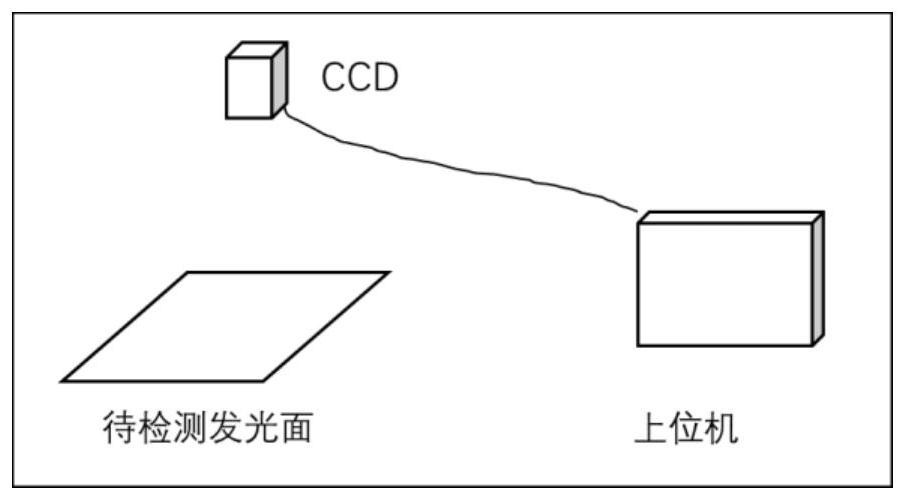

[0050] Step a1, take the light-emitting surface to be measured, and set the parameters of the CCD, including parameters such as focal length f, aperture F, gain GA, white balance parameter BA, exposure time T and working distance L, so that they are the same as the GCD parameters in the calibration step;

[0051] Step a2, in a dark room environment, imaging the luminous surface to be measured to obtain an imaging image I;

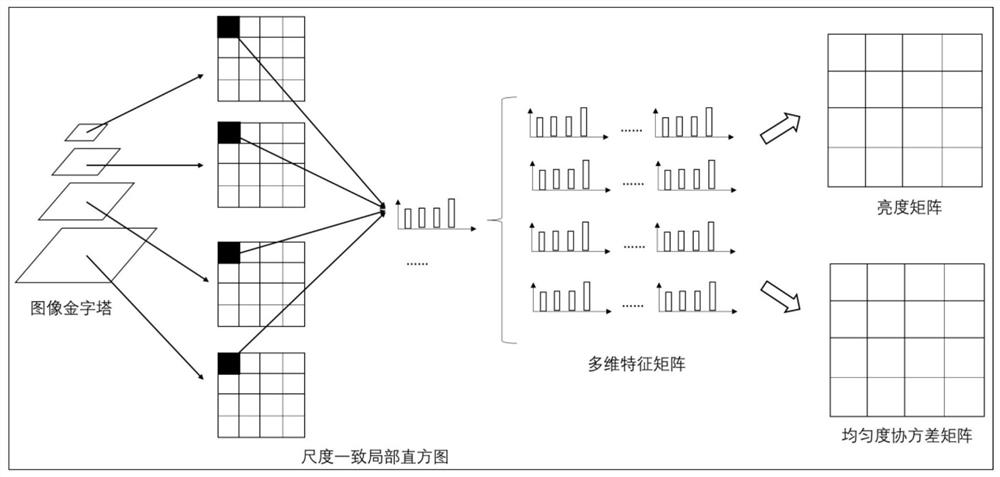

[0052] Step a3, extract the brightness feature matrix M and the uniformity feature U of the imaging image I, and the extraction process specifically includes the following steps:

[0053] Step a3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com