Assembling equipment for lightning arrester manufacturing and using method of assembling equipment

A technology for assembling equipment and lightning arresters, applied in the direction of resistance manufacturing, resistors, overvoltage protection resistors, etc., can solve problems such as inconvenient use, uneven force on the guide rod, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

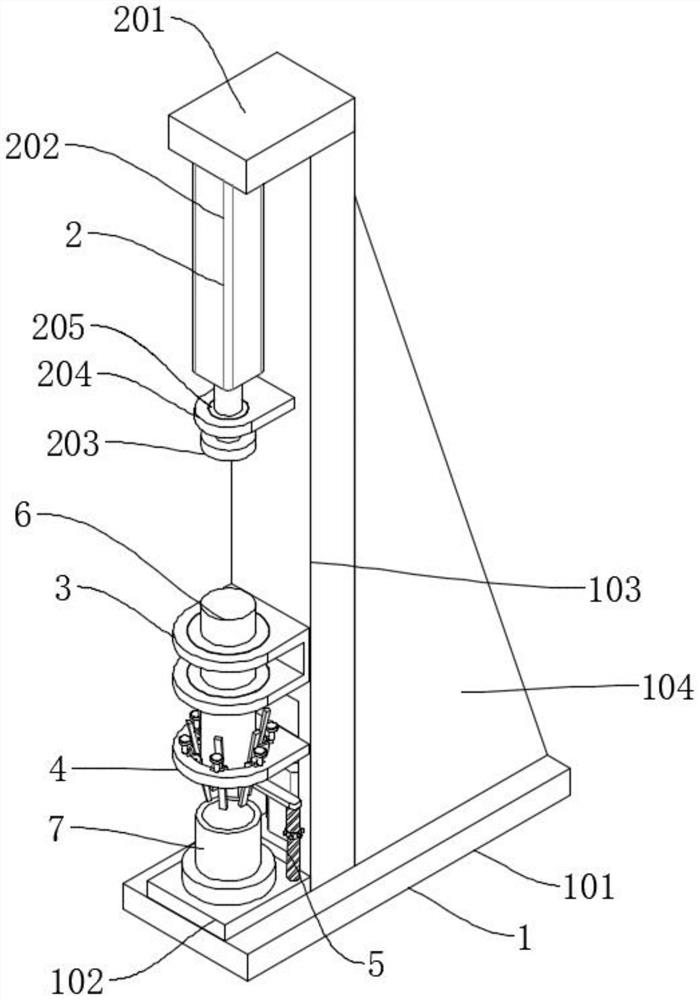

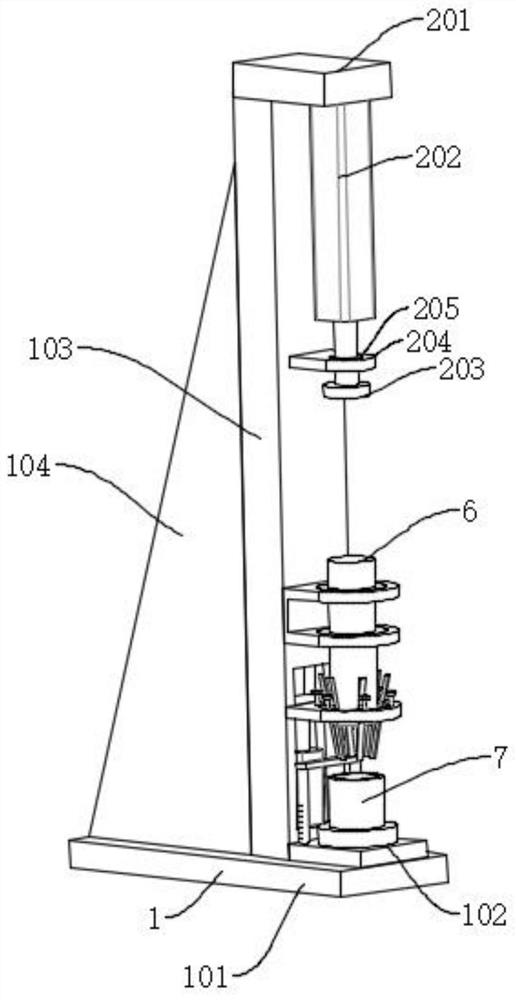

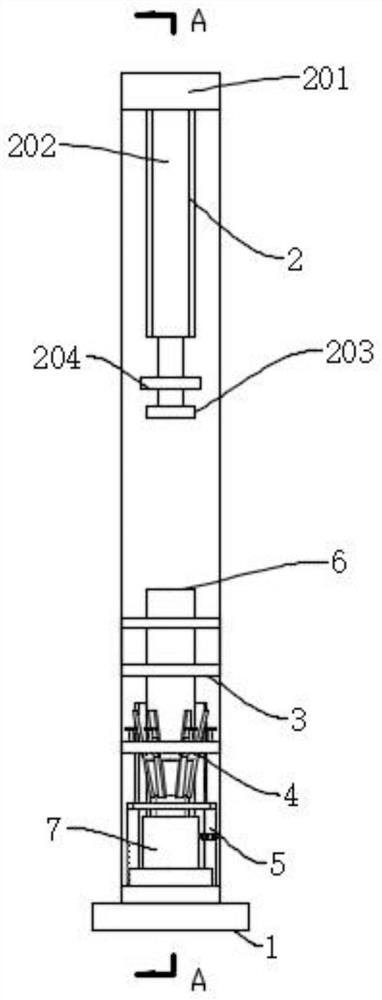

[0041] Such as Figure 1-7 As shown, an assembly device for arrester manufacturing includes a support mechanism 1, a pressing mechanism 2, an oxidation mandrel 6, and a surge arrester body 7. The support mechanism 1 is mainly composed of a bottom plate 101, a mounting seat 102, and a vertical plate 103. The top of the bottom plate 101 is welded There is a vertically arranged vertical plate 103, and the front end of the vertical plate 103 is provided with a horizontal mounting seat 102, and the mounting seat 102 is connected to the bottom plate 101 by bolts, and the top of the mounting seat 102 is provided with a mounting groove for clamping the arrester body 7, and the vertical plate The bottom of 103 is provided with a relief groove 1031, and the rear end of the vertical plate 103 is welded with a reinforcement plate 104, and the lower end of the reinforcement plate 104 is welded on the top of the bottom plate 101, and also includes a positioning mechanism 3 and an auxiliary m...

Embodiment 2

[0049] Such as Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that the adsorption assembly 404 includes an adjustment rod 4041 and a ring magnet 4043, the ring magnet 4043 is arranged outside the guide rod 403, and the bottom of the ring magnet 4043 is fixedly connected with several adjustment rods 4041, And the adjustment rod 4041 is screwed on the top of the fixing plate 401, so that the guide rod 403 can be adsorbed by the ring magnet 4043, and the function that the guide rod 403 is fixed is realized.

[0050] A method for using an assembly device manufactured by a lightning arrester, comprising the following steps:

[0051] Step 1: First, adjust the angle of the guide rod 403 and the height of the support plate 502 according to the model of the arrester body 7. By rotating the rotating rod 5042, the rotating rod 5042 drives the fixed sleeve 5041 to rotate, the fixed sleeve 5041 drives the screw rod 501 to rotate, and the screw rod 501 drives T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com