ERNiCrMo-11 welding wire and preparation method thereof

A welding wire and raw material preparation technology, which is applied in the field of alloys, can solve problems such as not being able to meet welding requirements, and achieve the effects of improving plasticity, removing non-metallic inclusions, and improving quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

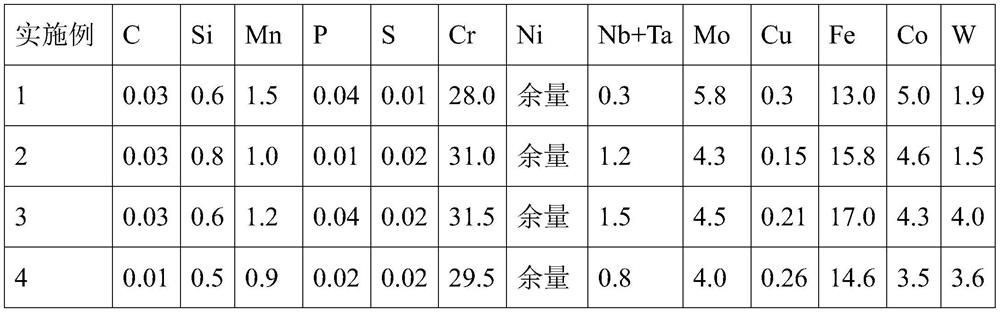

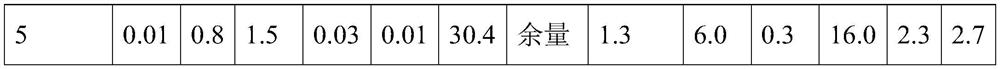

Examples

preparation example Construction

[0025] In addition, the present invention also provides a kind of preparation method as above-mentioned ERNiCrMo-11 welding wire, and this preparation method comprises the following steps:

[0026] (1) Raw material preparation: ingredients are distributed according to the design, and all materials are strictly baked according to the system; among them, all materials should meet the vacuum quality requirements, and the surface of the same steel type should be polished and the dosage should be ≤20%; moreover, in the ingredients During the process, the dosage of each element is strictly controlled;

[0027] (2) Vacuum smelting: Put the raw materials into the vacuum furnace for smelting, and follow the welding wire smelting process. The vacuum degree during the melting period is less than 8 Pa, and the vacuum degree during the refining period is ≤8Pa. No less than two high-temperature instant refining and one low-temperature long-term Refining, raising the steel temperature to 148...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com