Agricultural drip irrigation device

An agricultural and water tank technology, applied in agriculture, watering devices, climate change adaptation, etc., can solve problems such as unfavorable energy saving and environmental protection production requirements, water waste, and difficulty in controlling water supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

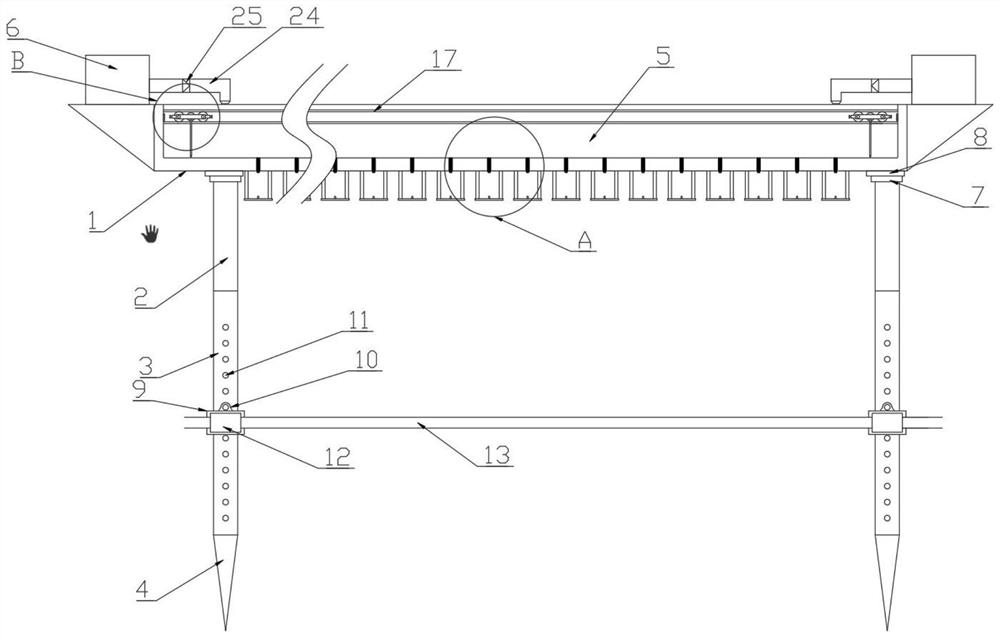

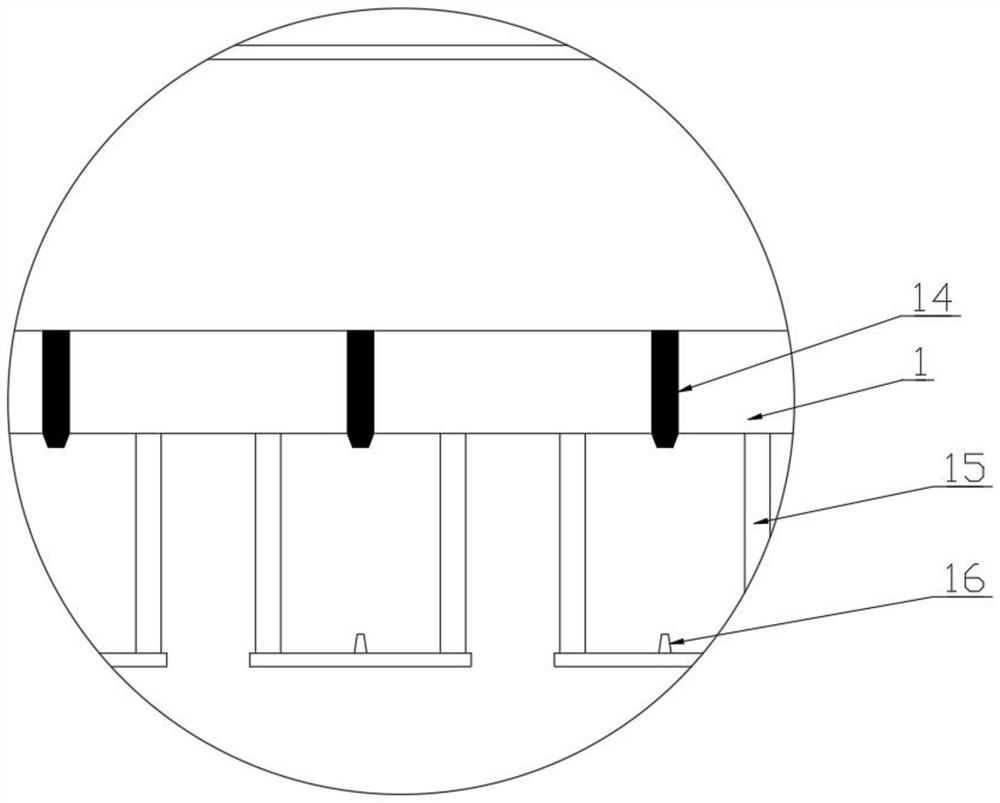

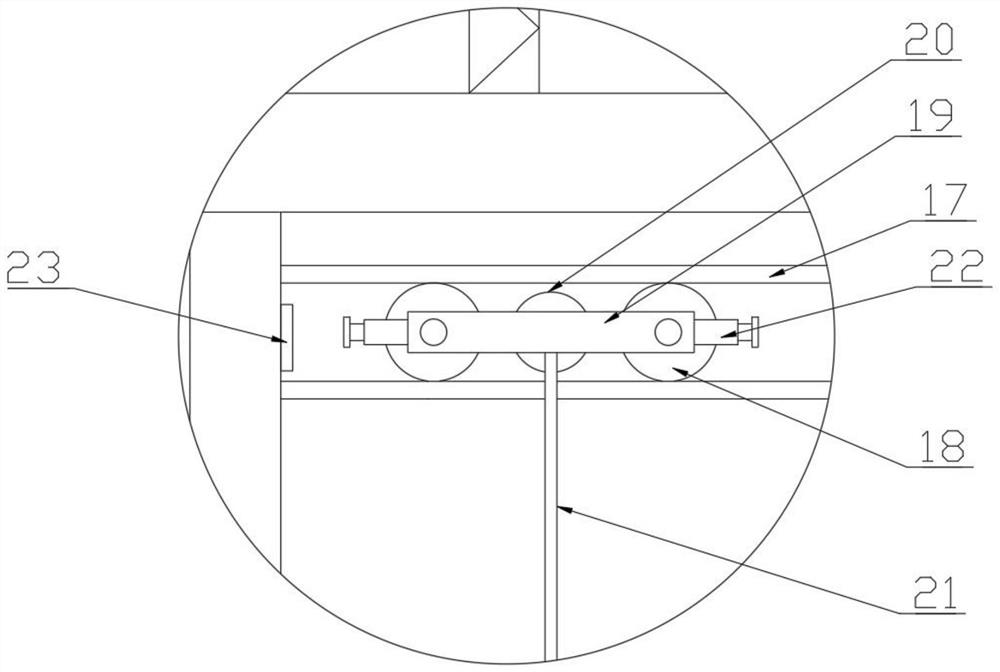

[0022] Please refer to the figure, in the embodiment of the present invention, an agricultural drip irrigation device includes a water tank 1, a sliding sleeve 2, a telescopic rod 3, a spike part 4, a wiper chamber 5 and a water tank 6; Both ends of 1 are provided with a vertical sliding sleeve 2, and the lower end of the sliding sleeve 2 slides through a vertical telescopic rod 3, and the telescopic rod 3 and the water tank 1 are fixed by fastening bolts, which is convenient for adjusting the sliding Cover 2, the length of the telescopic rod 3, thereby adjusting the height of the water tank 1; the lower end of the telescopic rod 3 is fixed with a vertically downward spiked part 4, through which the spiked part 4 can be inserted into the soil, and the drip irrigation device is fixed Above the crops; both ends of the water tank 1 are fixed with a water tank 6, which is connected by a pipeline water supply device to supply water to the water tank 6, and the bottom of the water ta...

Embodiment 2

[0027]On the basis of Embodiment 1, the outer sliding sleeve of the telescopic rod 3 is provided with a lifting seat 9, and the lifting seat 9 moves up and down on the outside of the telescopic rod 3, and the lifting seat 9 is fixedly provided with a positioning seat 10, and a Pin holes, insert positioning pins in the pin holes, several adjustment holes 11 are provided on the telescopic rod 3 corresponding to the pin holes on the positioning seat 10, and the adjustment holes 11 are arranged at equal intervals in the vertical direction, inserted into the In the adjustment holes 11 of different heights, the height of the lifting seat 9 is adjusted; the connecting seat 12 is connected with a universal joint on the lifting seat 9, and the connecting seat 12 is a hollow tube structure, and the connecting seat 12 can be adjusted to different directions. There is a hanging bar 13 passing through the connecting seat 12, and the hanging bar 13 is supported by the connecting seat 12. Adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com