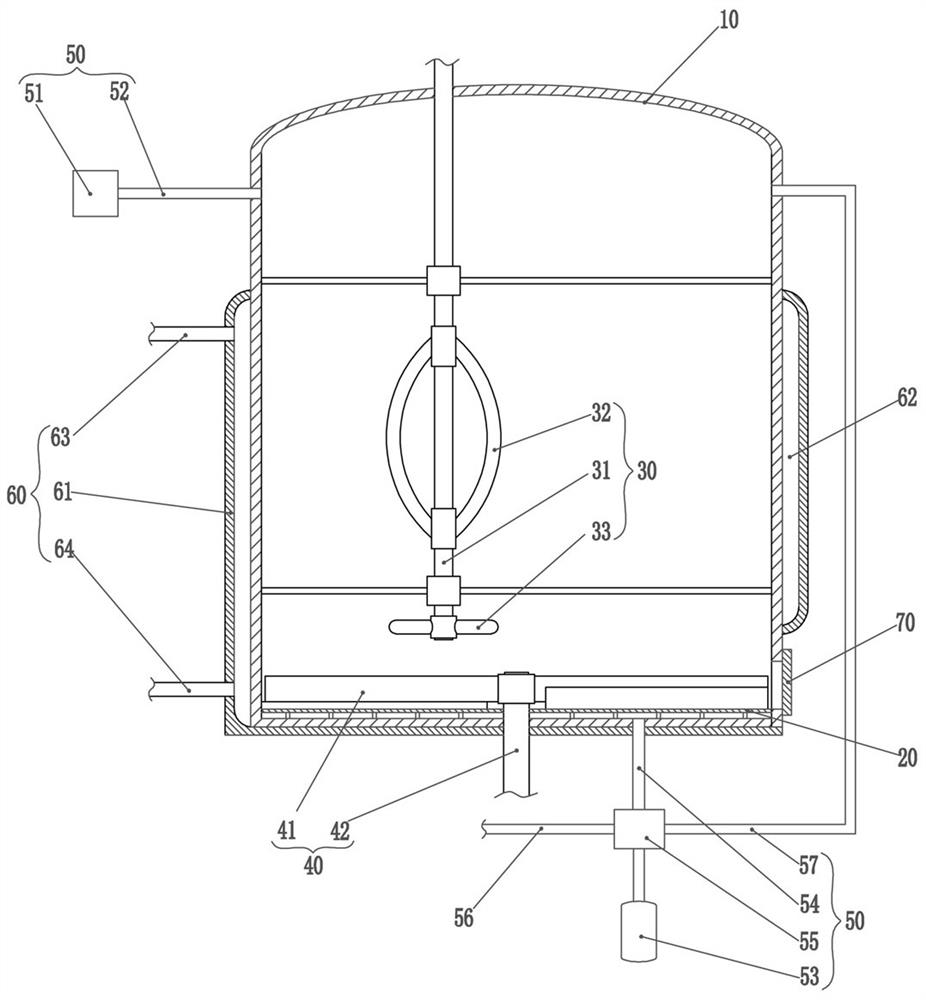

Device and method for extraction and separation of high-viscosity material

A separation device and high-viscosity technology, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of discontinuous material extraction and separation, troublesome material back and forth turnover, and difficult material separation, so as to achieve effective separation and good effect Good, high-strength extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

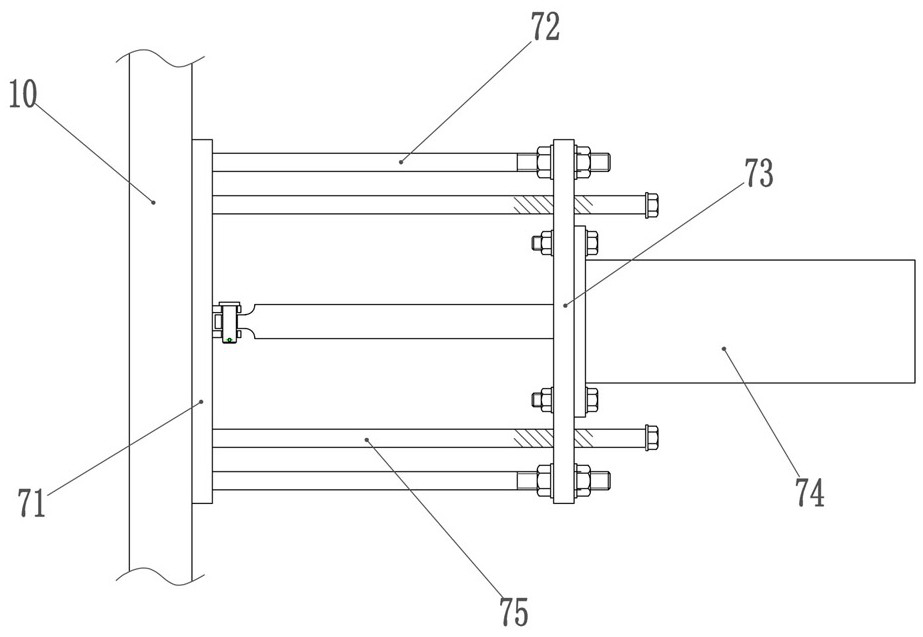

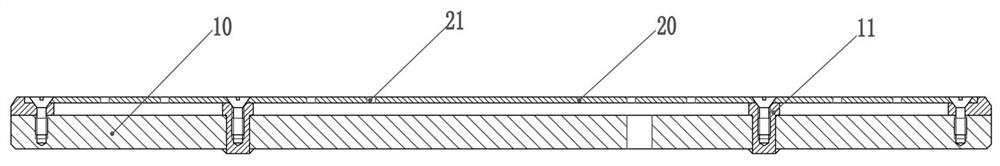

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1, a method for extracting and separating highly viscous materials, the method comprises the following steps:

[0085] Step S1, initial extraction; specifically includes:

[0086] Step S1-1, first open the solenoid valve on the water supply pipeline to add 1.8m 3 Then open the steam valve on the steam pipe to heat the water in the container to 96°C by means of steam heating;

[0087] Step S1-2, first turn on the upper agitator in the container to perform low-speed eccentric agitation of the water in the container, thereby hindering the rapid sinking of the material during feeding, and the speed of the upper agitator during low-speed eccentric agitation is 150r / s; The feeding port on the top of the container adds materials into the container according to the material-to-liquid ratio of 1:8, so that the temperature of the solid-liquid materials in the container after mixing is 94±0.5°C; High-speed eccentric stirring, the speed of the upper agitator is 600r / s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com