Waste gas treatment equipment for chemical engineering

A kind of exhaust gas treatment equipment and chemical technology, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc. It can solve the problems of slow filtration speed, failure to pass through the demister normally, and fast replacement speed of the demister.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

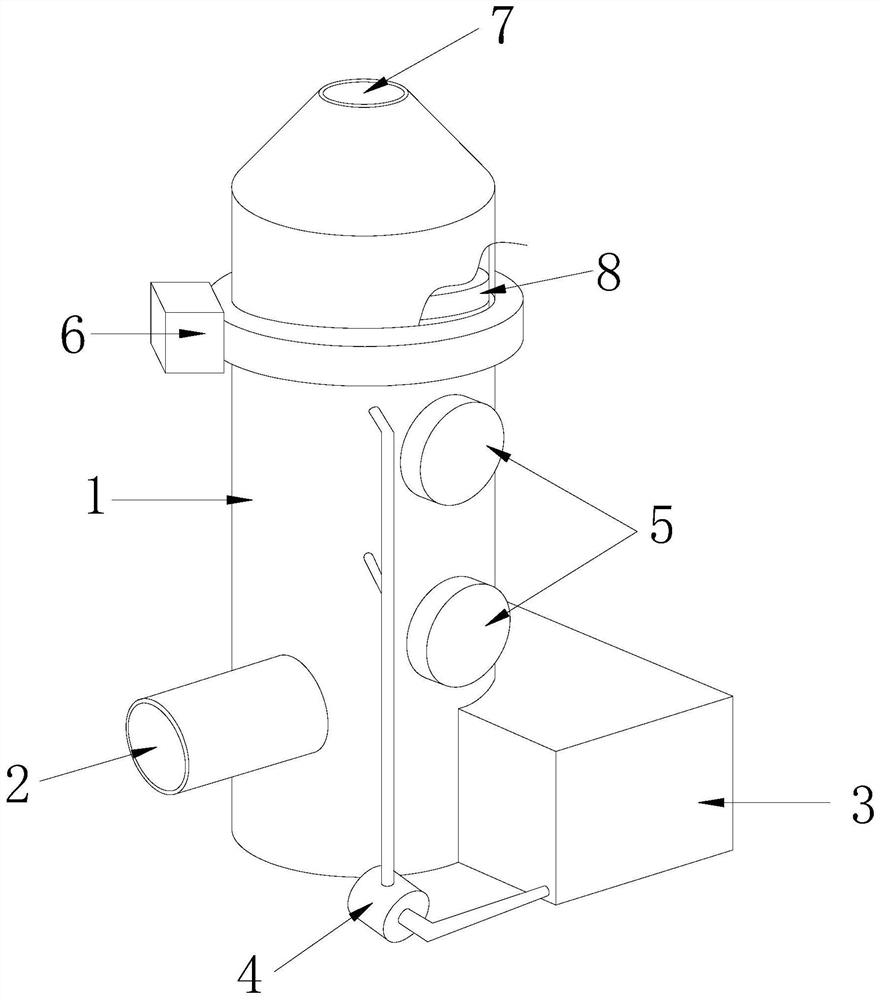

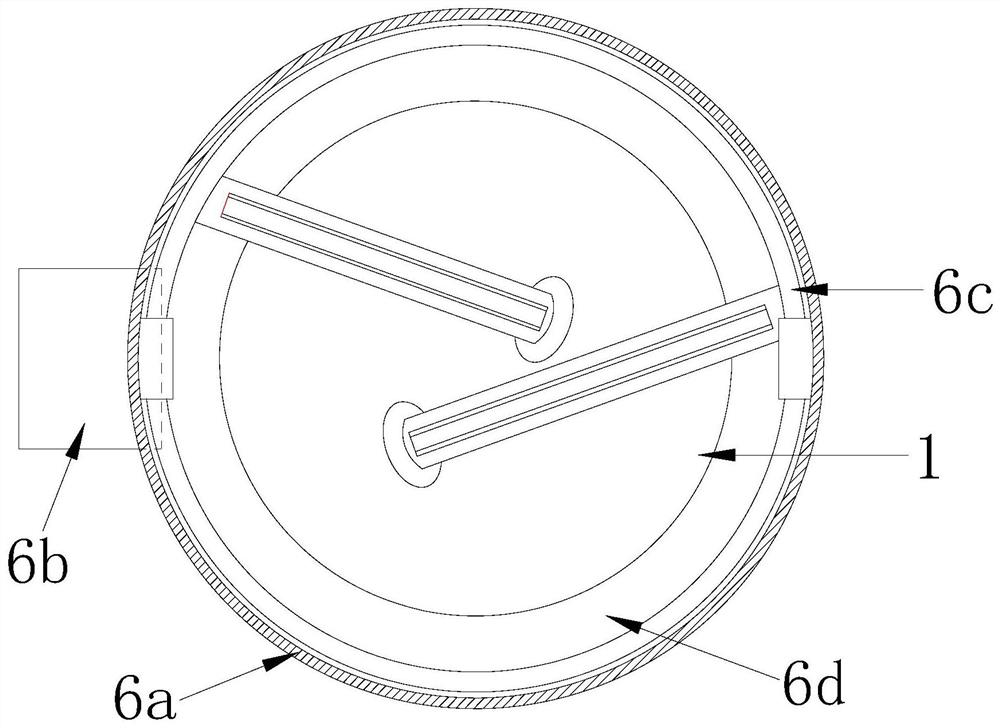

[0030] Such as Figure 1-Figure 6 As shown, the present invention provides a technical scheme of chemical waste gas treatment equipment:

[0031] Such as Figure 1-Figure 2 As shown, a chemical waste gas treatment equipment, its structure includes a tank body 1, a waste gas inlet 2, a water tank 3, a water pump 4, a maintenance door 5, a gas channeling acceleration device 6, and a waste gas outlet 7. The waste gas inlet 2 is located at The lower part of the front surface of the tank body 1, the water tank 3 is arranged on and connected to the front surface of the tank body 1, one end of the water pump 4 is connected to the water tank 3, and the other end is connected to the tank body 1, and the maintenance door 5 is provided together There are two and are respectively installed on the front surface of the tank body 1, the gas channeling acceleration device 6 is arranged on the upper part of the tank body 1, and is located on the lower surface of the demister 8, and the waste ...

no. 2 example

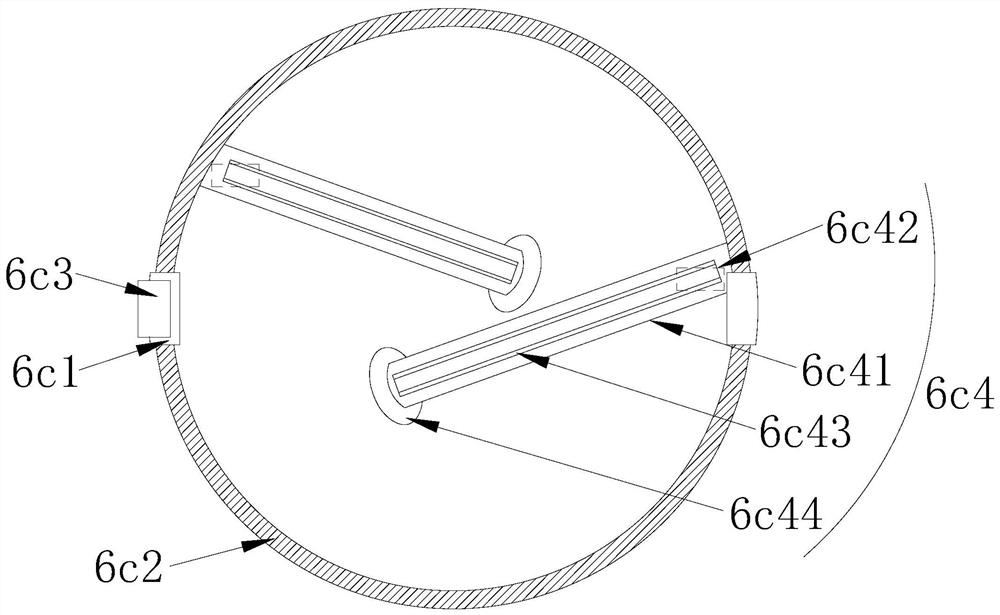

[0042] Such as Figure 5-Figure 6 As shown, the present invention provides a technical scheme of chemical waste gas treatment equipment:

[0043] Such as Figure 5-Figure 6 As shown, a kind of waste gas treatment equipment for chemical industry, its structure includes the said buckle chamber 6d including a chamber 6d1, orbital ring 6d2, movable hole 6d3, sealing ring strip 6d4, said orbital ring 6d2 is provided with two and respectively It is installed in the inner upper part of the cavity 6d1 in a spaced shape, and the track ring 6d2 cooperates with the sliding buckle g3. The movable hole 6d3 is set in the middle of the upper surface of the cavity 6d1 and is an integrated structure. The sealing ring 6d4 There are two parallel structures installed inside the movable hole 6d3 respectively, which are beneficial to realize the movable movement of the sticking and scraping component 6c4 and collect waste materials.

[0044] Such as Figure 5-Figure 6 As shown, a suction pump is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com