Horizontal spiral discharging and filtering centrifugal machine convenient to discharge

A horizontal screw and centrifuge technology, which is applied to centrifuges, centrifuges with rotating drums, mechanical equipment, etc., can solve the problems of inconvenient unloading of solid materials and increased humidity, so as to improve practicability and reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

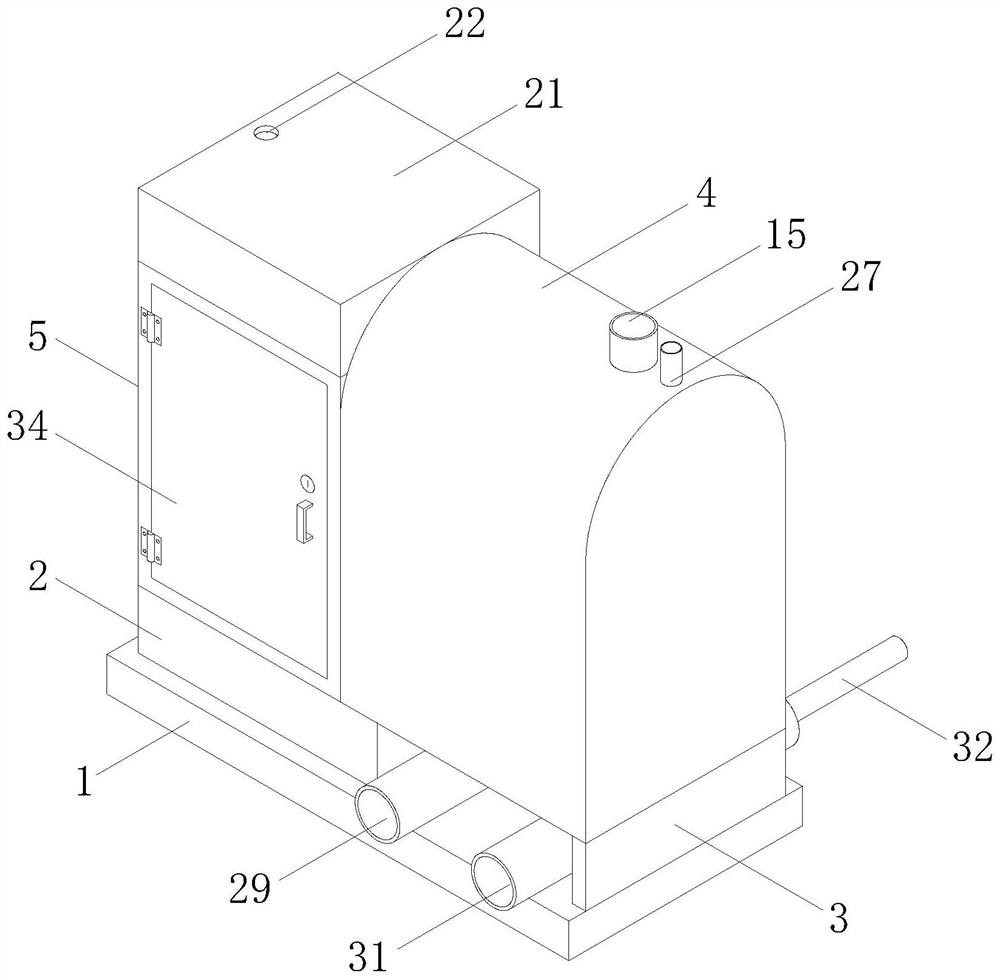

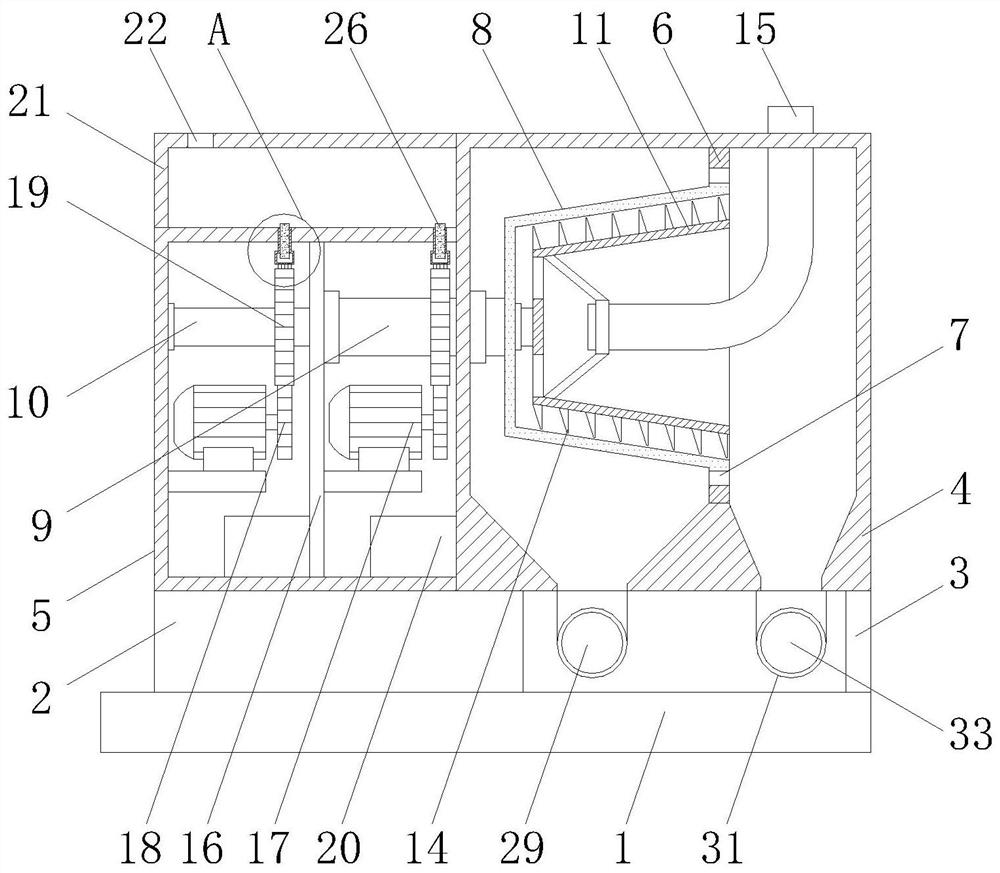

[0029] Example: such as Figure 1-6 , a horizontal spiral discharge filter centrifuge that is convenient for unloading according to the present invention includes a base 1, a pad 2 and a support block 3 on the right side of the pad 2 are fixedly installed on the top of the base 1, and the top of the pad 2 is fixed A protective box 5 is installed, and the top of the support block 3 is fixedly equipped with a centrifugal chamber 4, and the left side of the centrifugal chamber 4 is fixedly connected with the right side of the protective box 5, and the front of the protective box 5 is hinged with a protective door 27 through a hinge. Locks and handles are provided on the door 27;

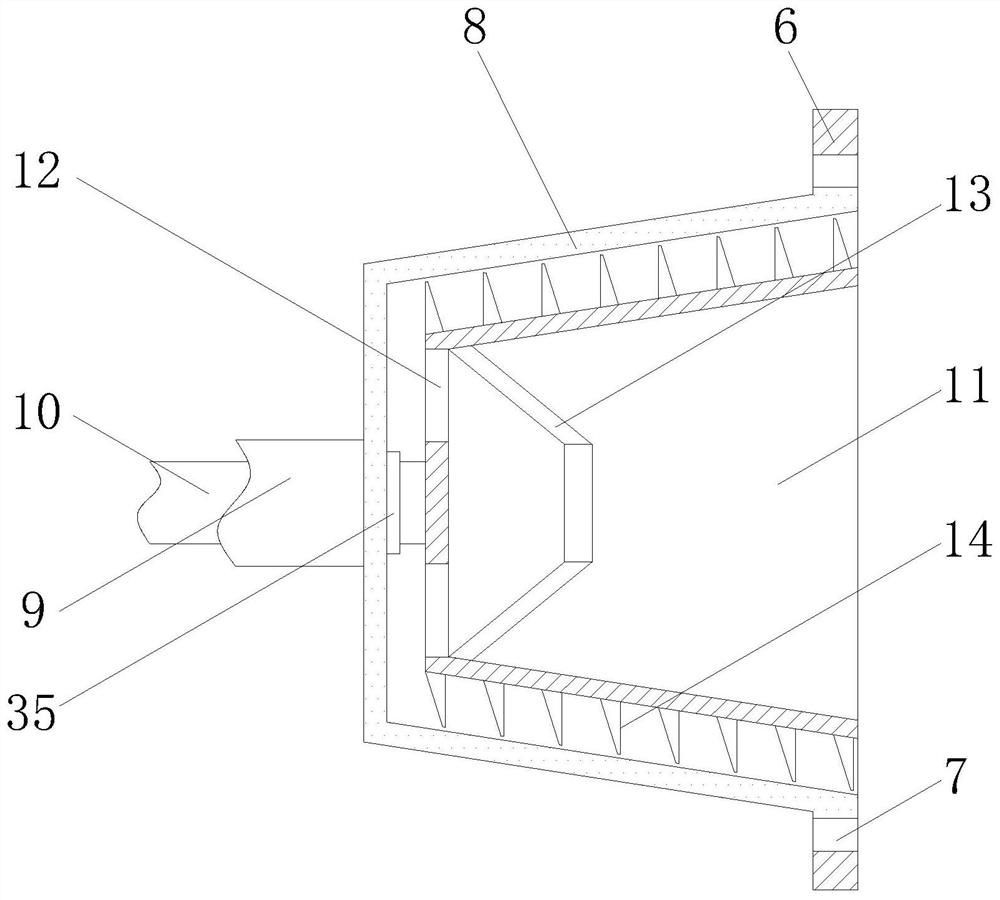

[0030] A centrifugal assembly is arranged between the centrifugal chamber 4 and the protective box 5, and the centrifugal assembly consists of a partition plate 6, a first sealed bearing 7, a drum 8, a rotating shaft 9, a rotating tube 10, an inner cylinder 11, two It is composed of feed port 12, a pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com