Carbon fiber cloth production process and improved filament collecting device thereof

A production process and technology of carbon fiber cloth, applied in the directions of fiber chemical characteristics, dry gas arrangement, transportation and packaging, etc., can solve the problems of poor uniformity of carbon fiber filaments, unreusable water, insufficient catalyst solution solution, etc. Uniformity, improved usability, improved tumble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

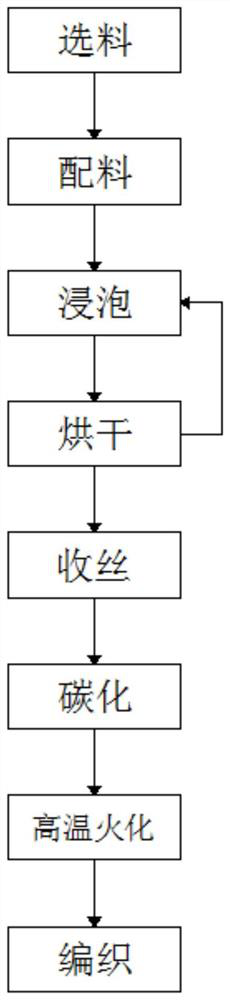

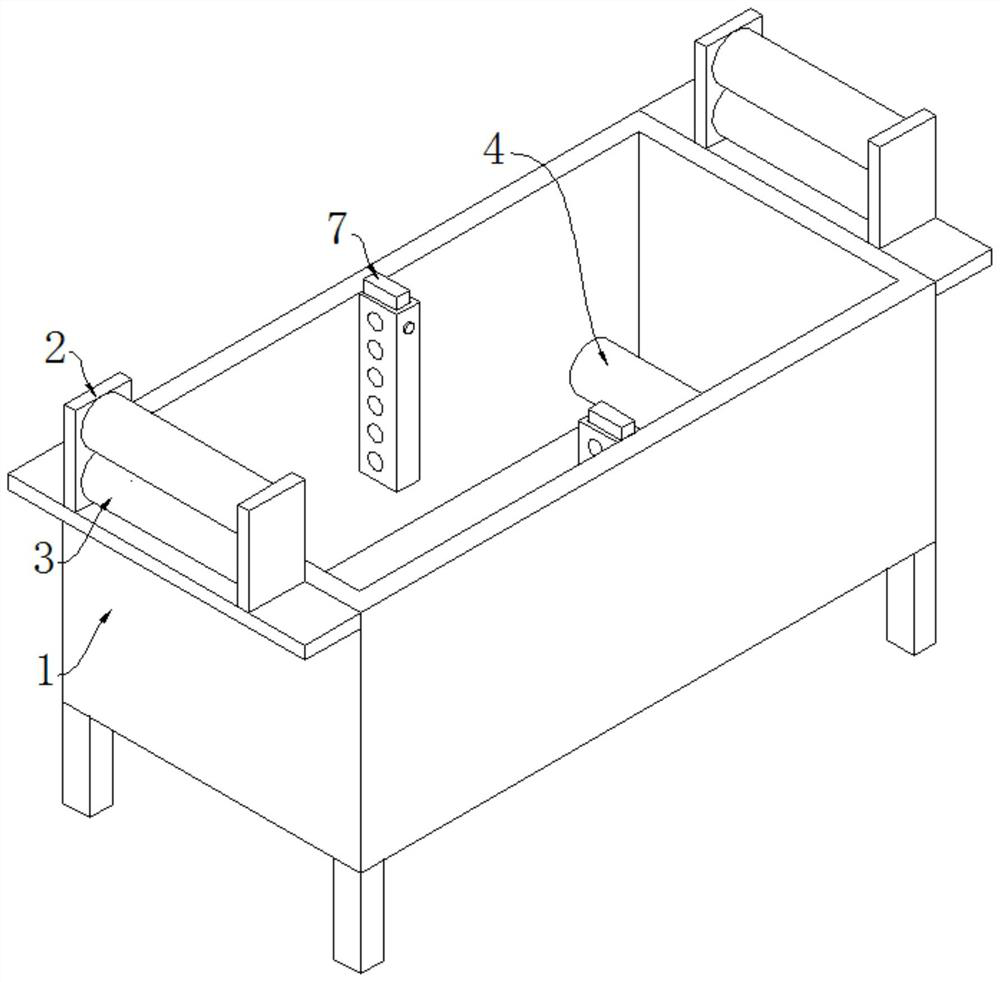

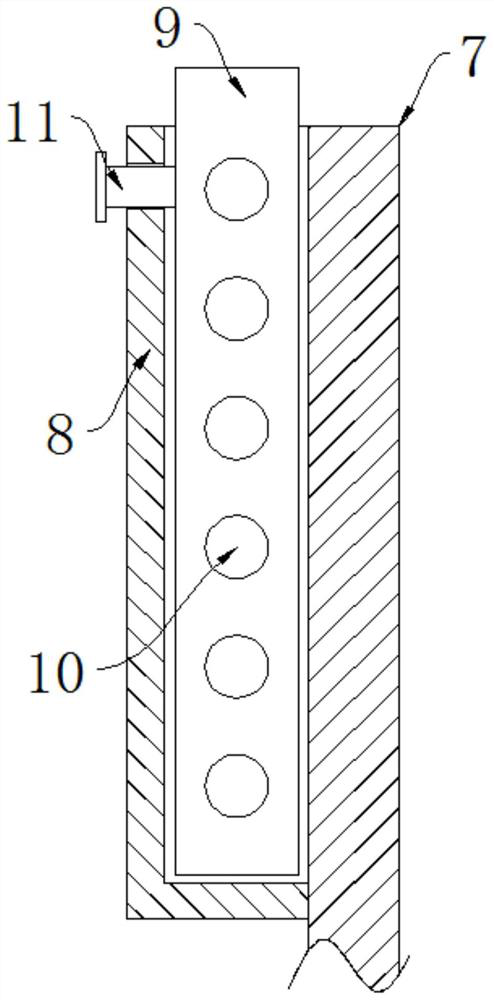

[0044] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown in Fig. 10, a carbon fiber cloth production process and its improved wire collection device of the present invention include the following steps:

[0045] S1, material selection, select carbon fiber precursor;

[0046] S2, batching, configure the catalyst solution, put the chloride, bromide and ammonium dihydrogen phosphate into the soaking mechanism according to the ratio of 1: 1.5: 2, and mix with 500L of water to prepare a 6%-12% catalyst solution;

[0047] S3, soaking, putting the carbon fiber precursor into the soaking mechanism, so that the carbon fiber precursor is soaked in the catalyst solution of 6%-12%, and the soaking time is controlled at 20min;

[0048] The soaking mechanism is composed of a soaking tank 1, two drain pipes 12 and two valves 13. The tops of the two drain pipes 12 are fixedly communicated with both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com