Preparation method of high-purity cardol

A high-purity cardolol technology, applied in the field of preparation of high-purity cardolol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

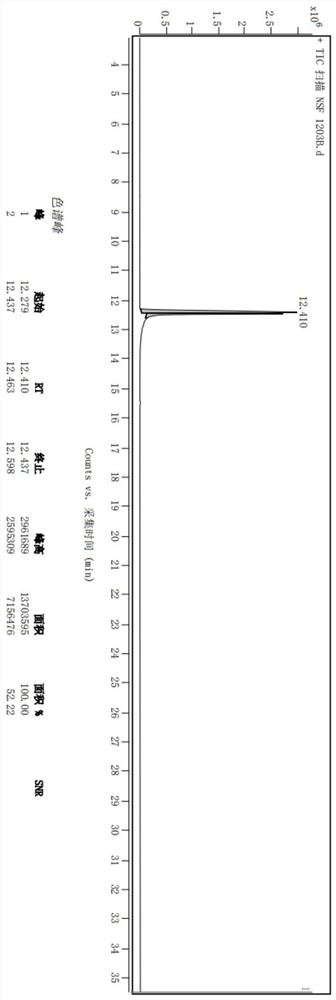

Embodiment 1

[0039] The first step is molecular distillation. After decarboxylation, the cashew nut shell oil is sent to a thin film evaporator for distillation. The set temperature of the thin film evaporator is 170°C and the vacuum degree is 150Pa; The set temperature of the primary molecular distillation is 200°C, and the vacuum degree is 10Pa; the light components obtained by distillation in the primary molecular distillation tower are sent to the secondary molecular distillation tower for distillation, and the set temperature of the secondary molecular distillation is 173°C, and the vacuum degree is 8Pa; The heavy component that grade molecular distillation tower steams is the cardol product, reaches more than 70% by the purity of detecting described cardol product, and the distillation yield of described cardol product is 64.3% (calculation of distillation yield The formula is: the quality of cardol / the quality of cashew nut shell oil after decarboxylation×100%).

[0040] In the seco...

Embodiment 2

[0044] The first step is molecular distillation. After decarboxylation, the cashew nut shell oil is sent to a thin-film evaporator for distillation. The set temperature of the thin-film evaporator is 180°C and the vacuum degree is 160Pa; The set temperature of the primary molecular distillation is 205°C, and the vacuum degree is 12Pa; the light components obtained by distillation in the primary molecular distillation tower are sent to the secondary molecular distillation tower for distillation, and the set temperature of the secondary molecular distillation is 175°C, and the vacuum degree is 10Pa; The heavy component that grade molecular distillation tower steams is the cardol product, reaches more than 70% by the purity of detecting described cardol product, and the distillation yield of described cardol product is 64.1% (calculation of distillation yield The formula is: the quality of cardol / the quality of cashew nut shell oil after decarboxylation×100%).

[0045] In the sec...

Embodiment 3

[0049] The first step is molecular distillation. After decarboxylation, the cashew nut shell oil is sent to a thin film evaporator for distillation. The set temperature of the thin film evaporator is 175°C and the vacuum degree is 155Pa; The set temperature of the primary molecular distillation is 195°C, and the vacuum degree is 10Pa; the light components obtained by distillation in the primary molecular distillation tower are sent to the secondary molecular distillation tower for distillation, and the set temperature of the secondary molecular distillation is 170°C, and the vacuum degree is 10Pa; The heavy component that grade molecular distillation tower steams is the cardol product, reaches more than 70% by the purity of detecting described cardol product, and the distillation yield of described cardol product is 64.0% (calculation of distillation yield The formula is: the quality of cardol / the quality of cashew nut shell oil after decarboxylation×100%).

[0050] In the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com