Coke oven on-line thermotechnical test method

A test method and technology of coke oven, which is applied in coke oven, machine/structural component test, petroleum industry, etc., and can solve problems affecting calculation accuracy, poor timeliness, long time span, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

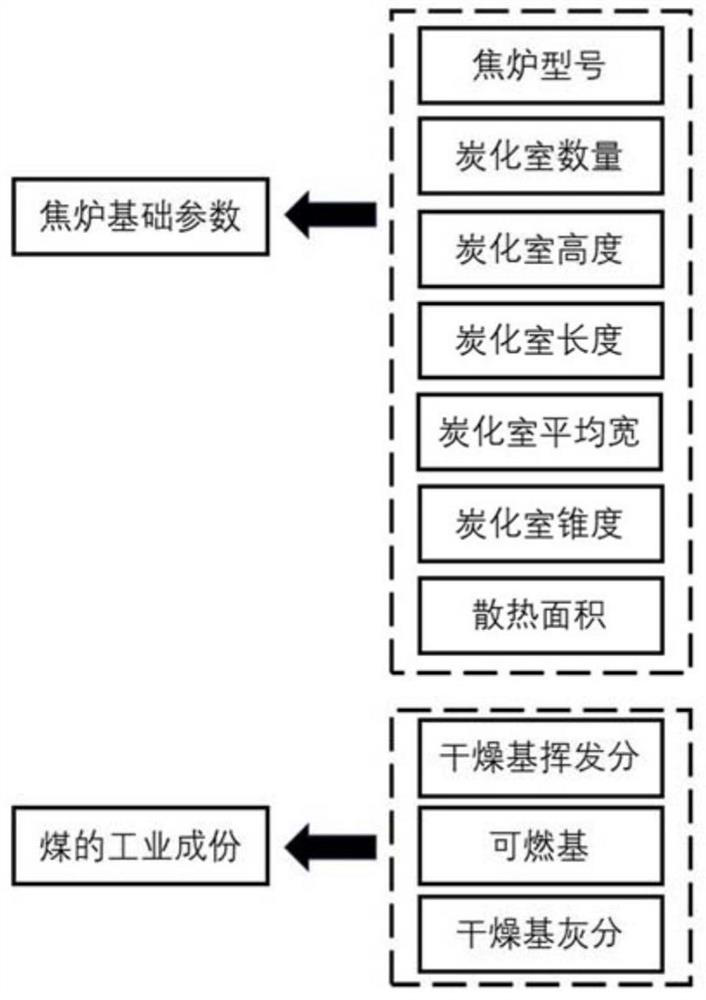

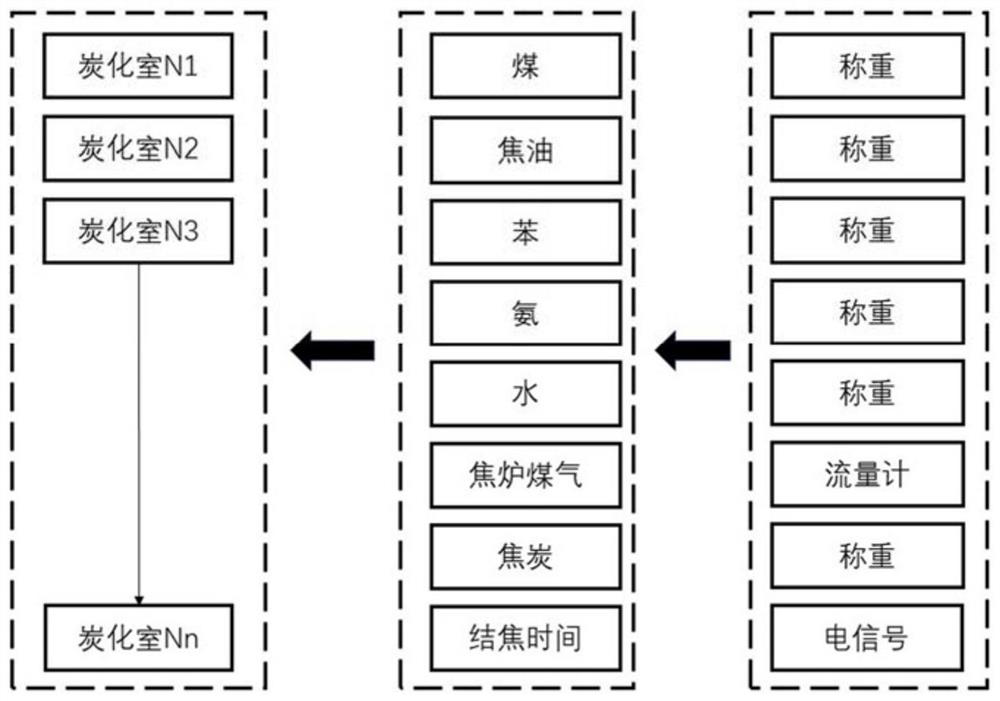

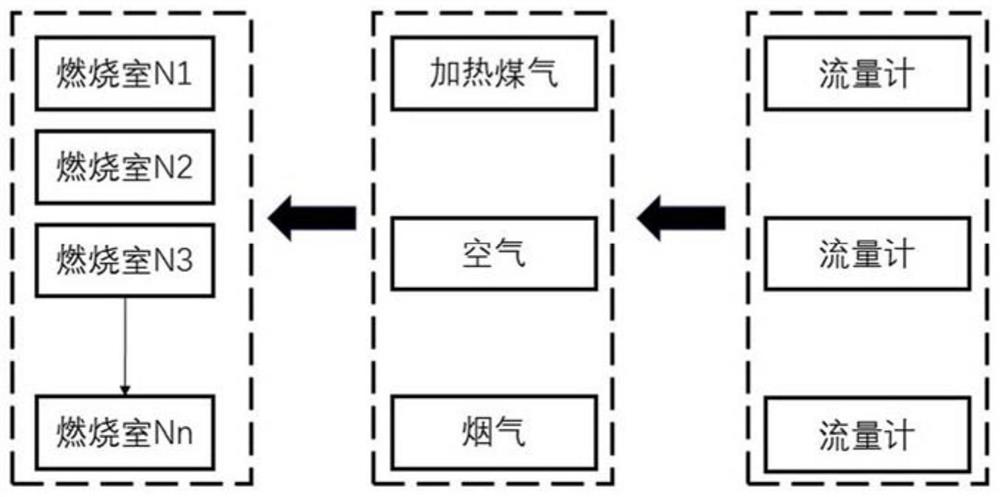

[0118] In order to achieve online thermal testing of coke ovens and achieve real-time production and consumption tracking analysis of the coking oven coking process, the present invention provides an online thermal testing method for coke ovens, which is based on process signals in the coking oven coking process, The real-time online thermal test results are obtained through the correlation model and algorithm, and the test results are diagnosed and analyzed to guide the deficiencies in coke oven production, so as to achieve the improvement of thermal efficiency, the reduction of gas heat consumption per ton of product, and the coking process of coke ovens. Online diagnosis and analysis of the effect of energy saving and consumption reduction.

[0119] The specific steps of the present invention are described in detail. The coke oven online thermal testing method includes:

[0120] Step 1. Obtain basic signals, material signals, and heat signals in real time, summarize all si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap