Natural gas hydrate synthesis reaction kettle and synthesis method thereof

A technology for synthesis reaction and natural gas, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of inconvenient transfer of combustible ice, collection and storage of inconvenient combustible ice, slow hydration reaction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

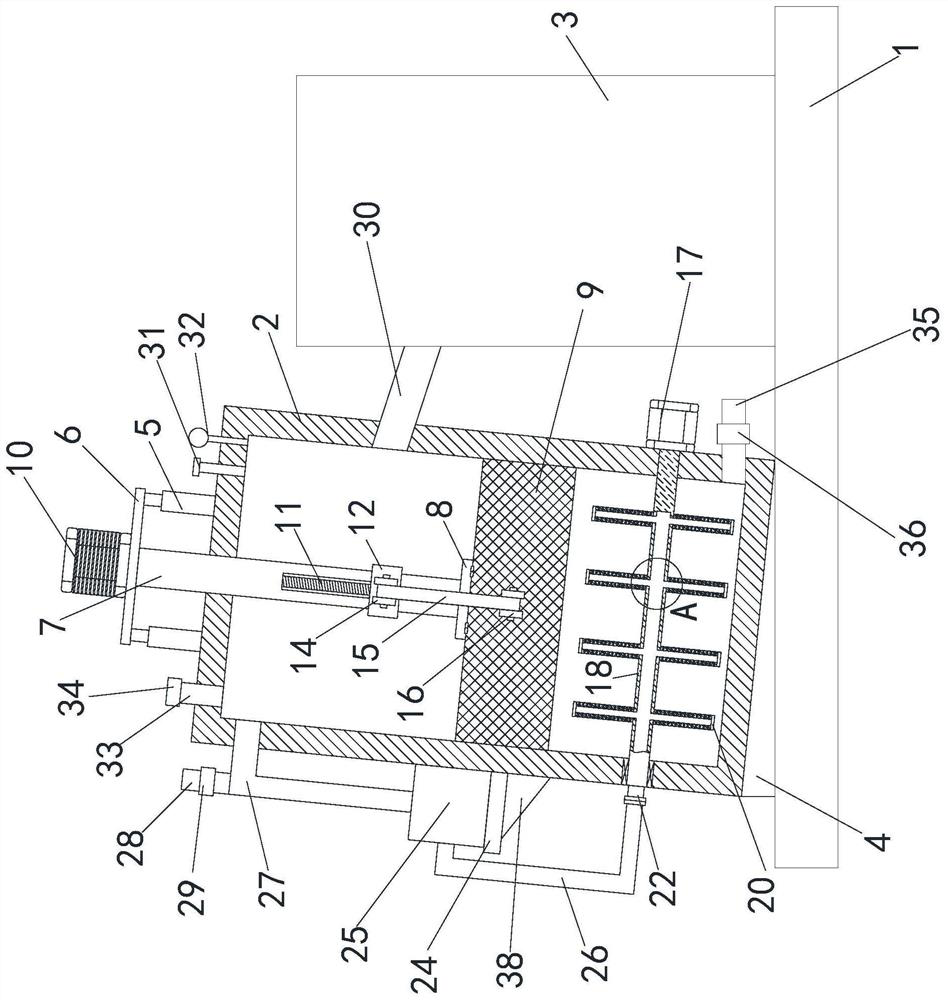

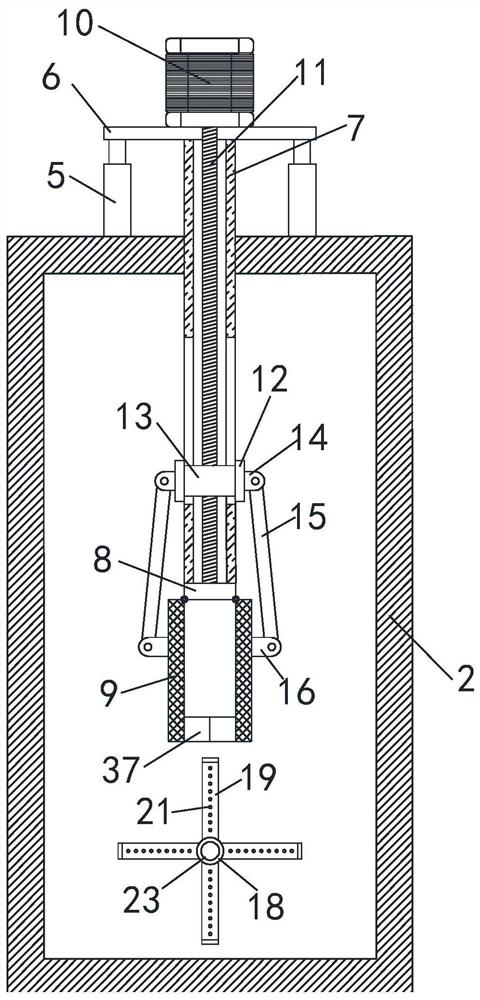

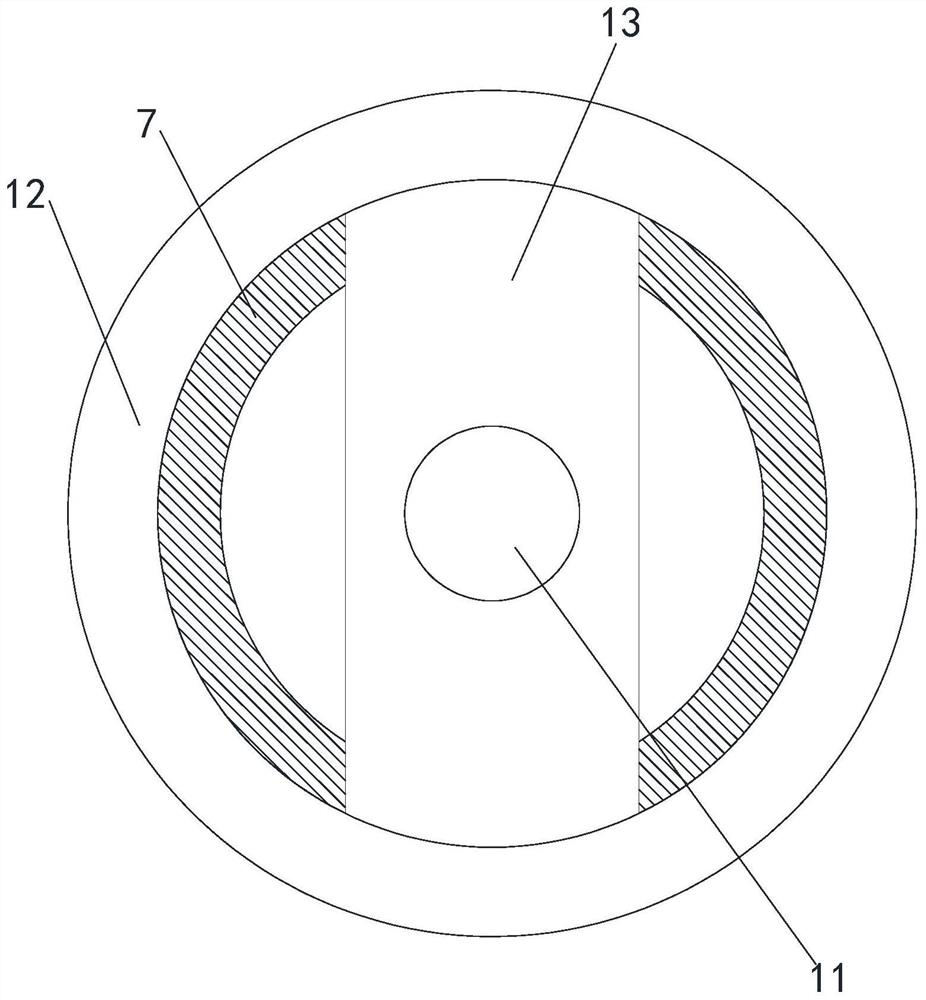

[0031] see Figure 1-4, a natural gas hydrate synthesis reaction kettle and a synthesis method thereof, comprising a bottom plate 1, a reaction box 2 and a storage box 3, the left side of the top of the bottom plate 1 is fixedly connected with a triangular plate 4, the bottom of the reaction box 2 It is fixedly connected with the top of the triangular plate 4, the top of the reaction box 2 is fixedly connected with four electric cylinders 5, the tops of the four electric cylinders 5 are fixedly connected with a fixed plate 6, and the bottom end of the fixed plate 6 is fixedly connected with a fixed pipe 7, The bottom end of the fixed tube 7 runs through the reaction box 2 and extends to the inside of the reaction box 2. The fixed tube 7 is slidingly fitted with the reaction box 2. The bottom end of the fixed tube 7 is fixedly connected with a connecting plate 8, and the left side of the bottom end of the connecting plate 8 and the right side are hingedly connected with a mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com