Mechanization device for continuously and freely heightening corrugated beam guardrail

A wave beam guardrail, free technology, used in road safety devices, roads, roads, etc., can solve the problems of large workload and inability to achieve flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

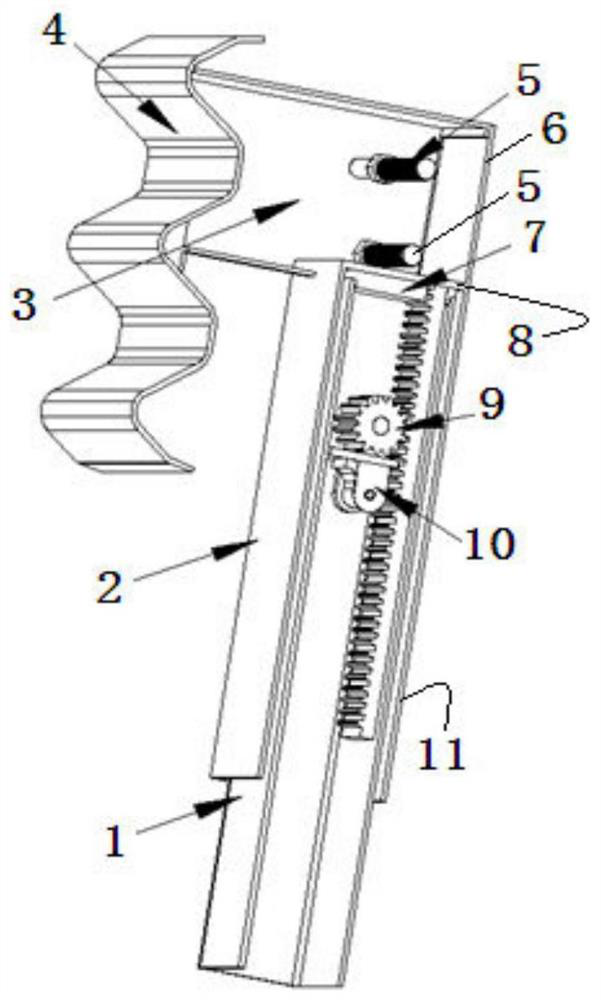

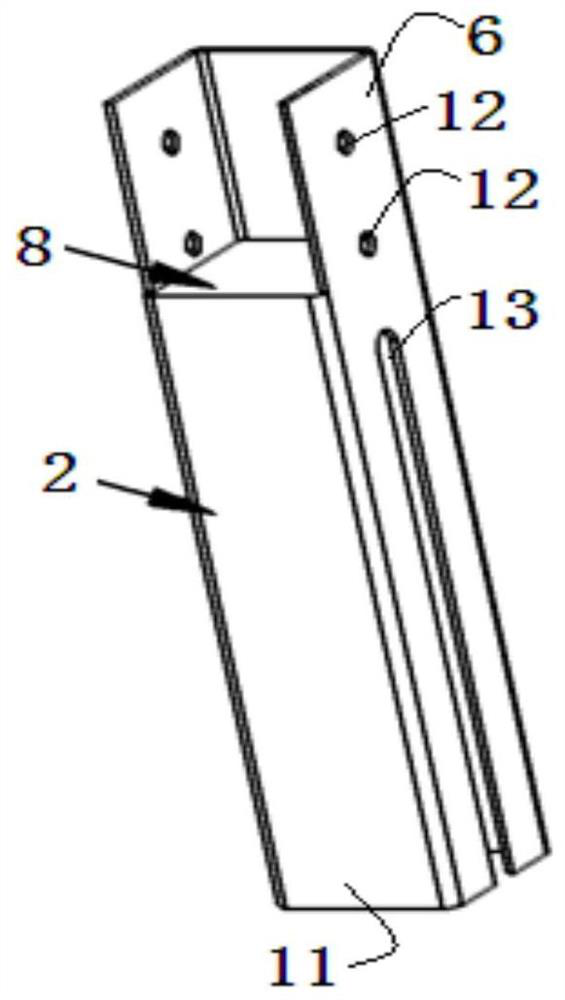

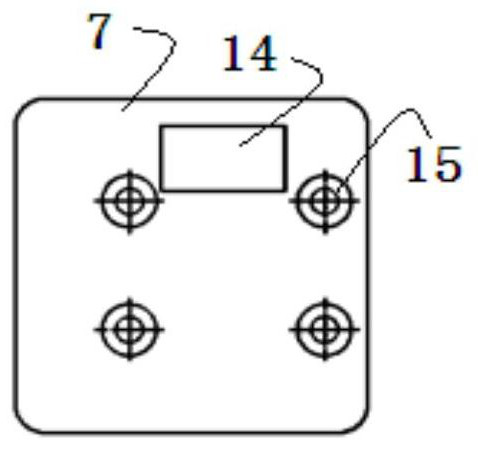

[0026] Below with the accompanying drawings ( Figure 1-Figure 8 ) to illustrate the present invention.

[0027] figure 1 It is a structural schematic diagram of a mechanized device for realizing the continuous and free heightening of the corrugated beam guardrail according to the present invention. figure 2 yes figure 1 Schematic diagram of the structure of the middle and outer sleeve assembly 2. image 3 yes figure 1 Schematic diagram of the structure of the middle guide cover 7. Figure 4 yes figure 1 Schematic diagram of the structure of the middle rack and pinion device 9. Figure 5 yes Figure 4 Schematic diagram of the structure of the middle gear seat 18. Figure 6 yes figure 1 Schematic diagram of the structure of the middle one-way stop device 10. Figure 7 yes figure 1 Schematic diagram of the rear view section structure. Figure 8 yes figure 1 Schematic diagram of the side view structure. refer to Figure 1 to Figure 8 As shown, a mechanized device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com