Internal gear machine with hydrostatically supported inner sealing part on filler piece

A technology of seals and gears, which is applied to rotary piston type/swing piston type pump components, liquid fuel engines, pump components, etc., can solve problems such as low cost and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

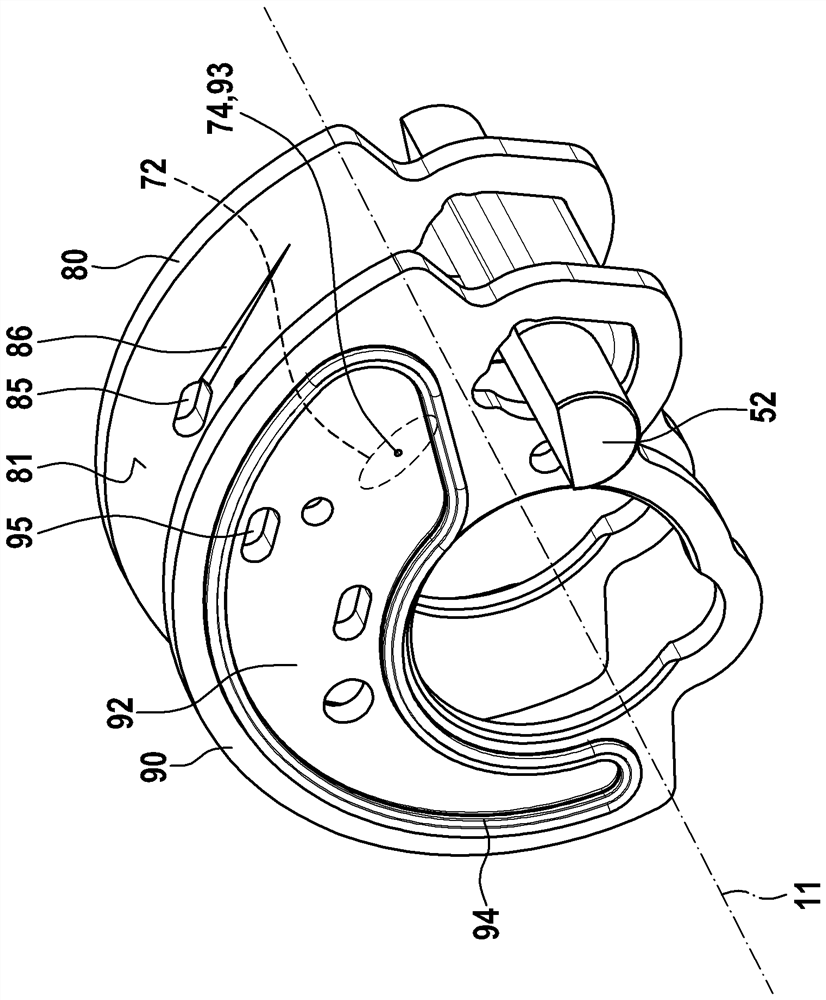

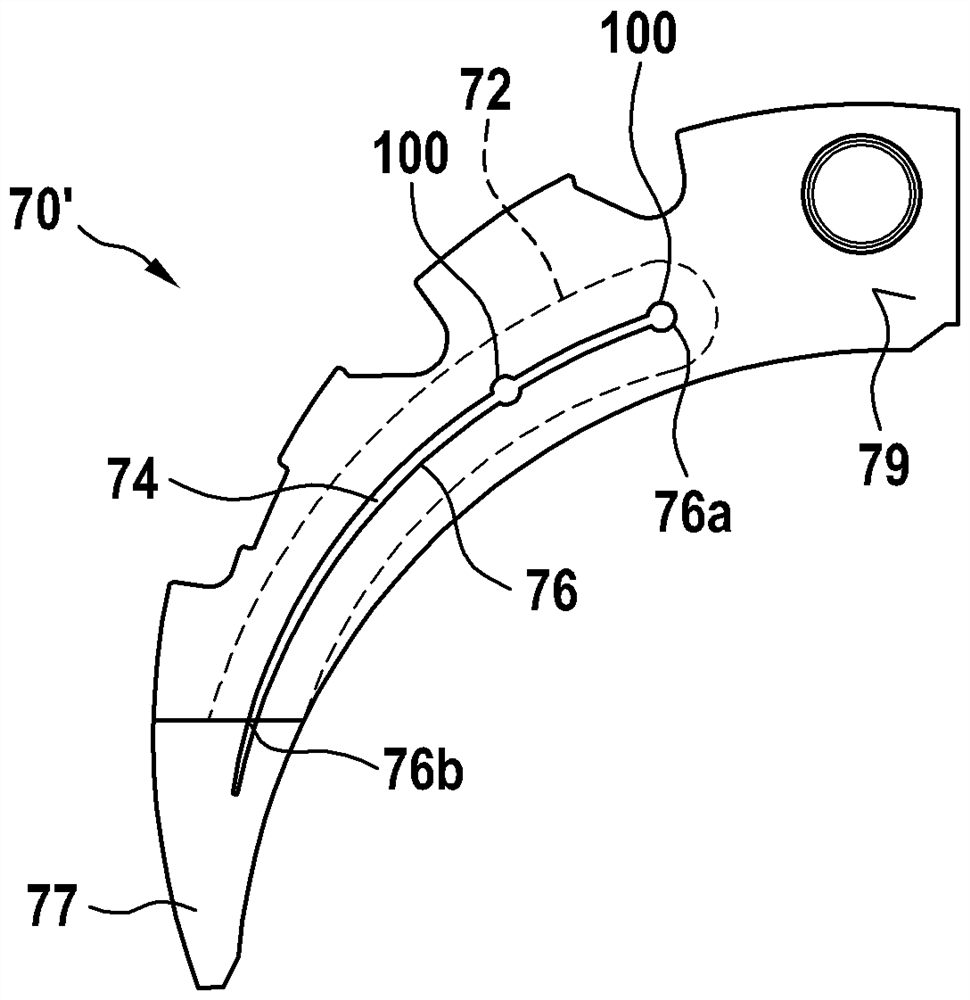

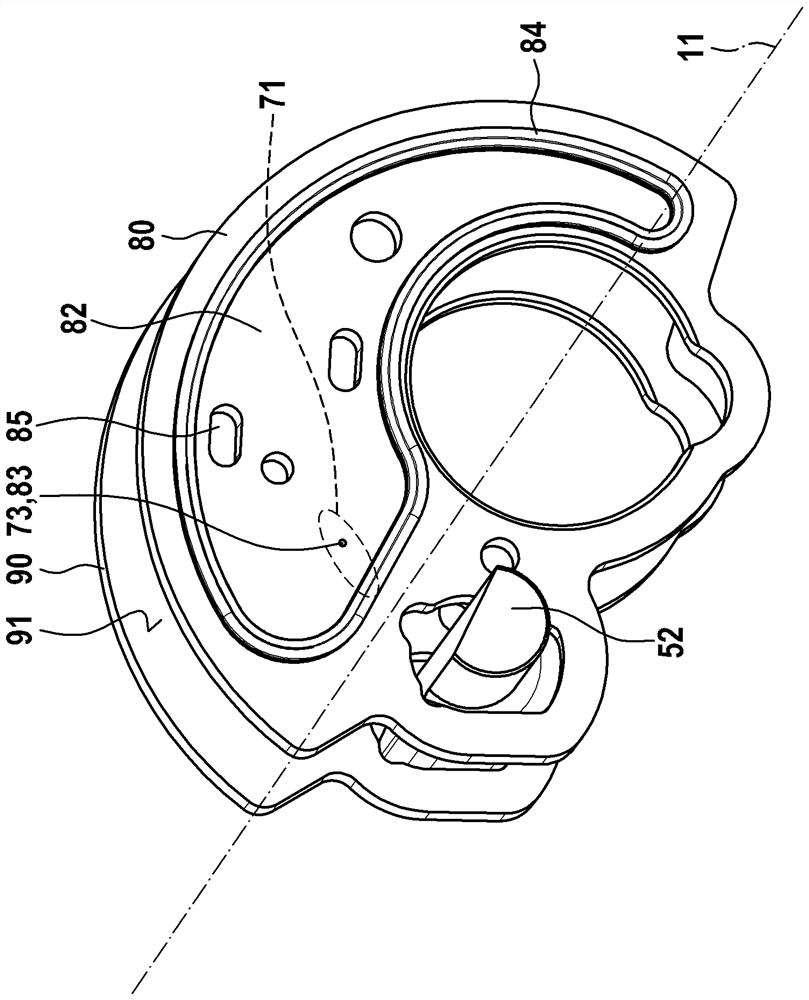

[0024] figure 1 A perspective view of the internal gear machine 10 according to the invention is shown. The internal gear machine 10 comprises a housing 20 which in the present case consists of a first, second and third housing part 21 ; 22 ; 23 . The housing parts 21 ; 22 ; 23 are each formed as a plate, wherein they are arranged next to each other in the sequence described and are firmly connected to one another. They rest in pairs on planar surfaces oriented perpendicular to the axis of rotation 11 . High-pressure and low-pressure connections 24 ; 25 are provided on the second housing part 22 . The current internal gear machine 10 is designed for operation as a pump, so that the low-pressure connection 25 has a larger cross-section than the high-pressure connection 24 .

[0025] The drive shaft 12 protrudes with a drive journal from the housing 20 , in particular from the first housing part 21 , so that the drive shaft can be in a rotational drive connection with an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com