Wear protection layer assembly and component with wear protection layer

A protection layer and component technology, which is applied in the field of manufacturing the wear protection layer component and the hydrogen-containing amorphous carbon layer, can solve the problems of reducing the wear resistance of the carbon layer and the like, and achieve the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

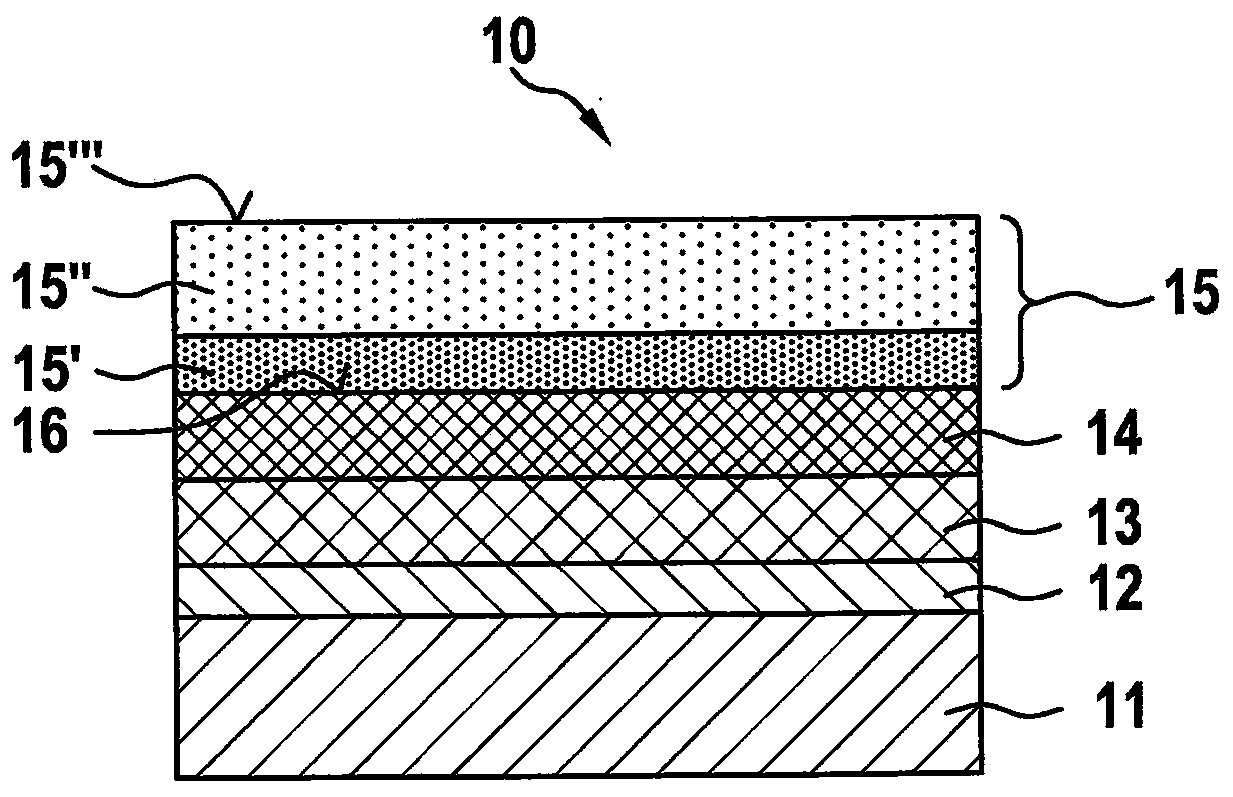

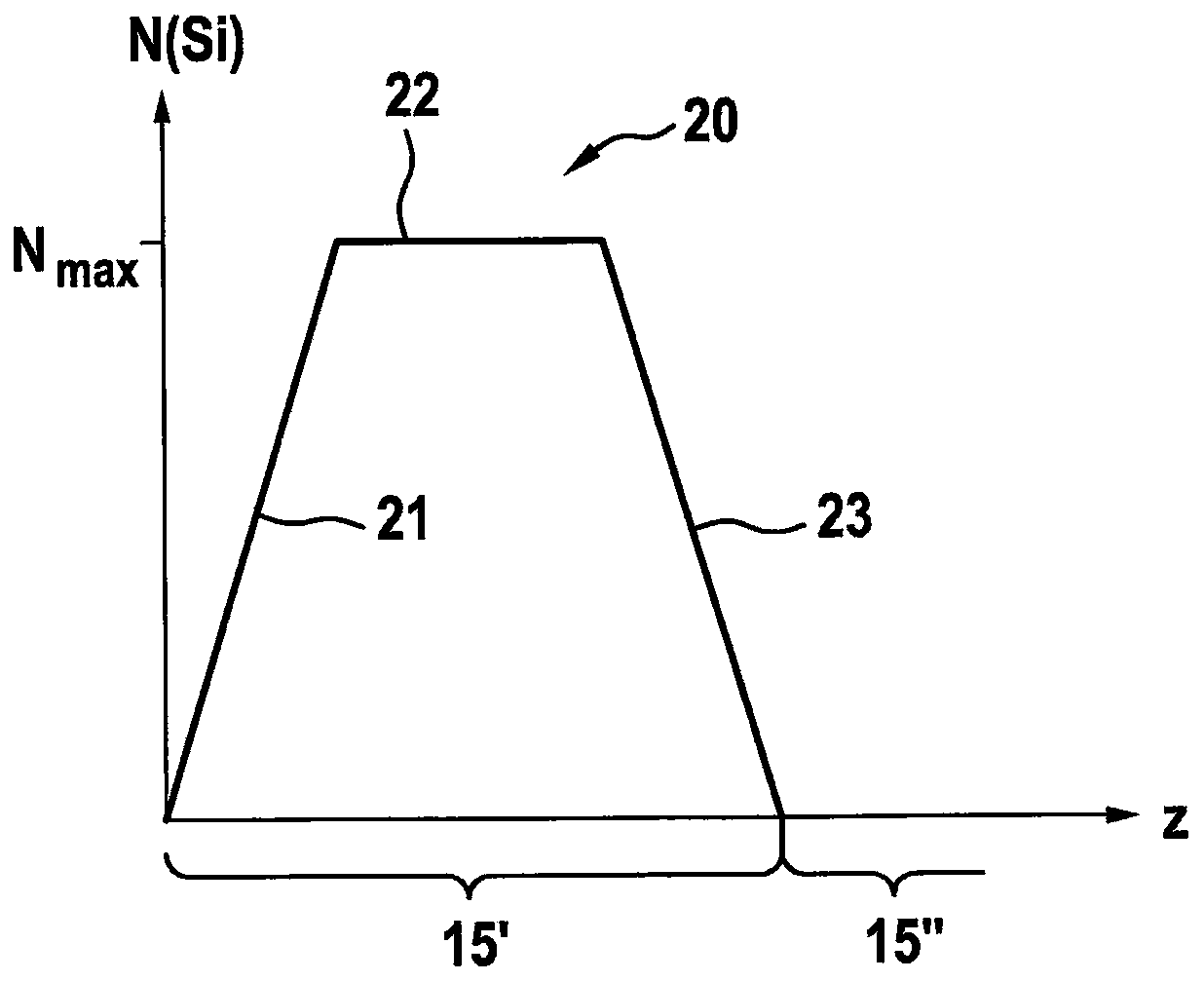

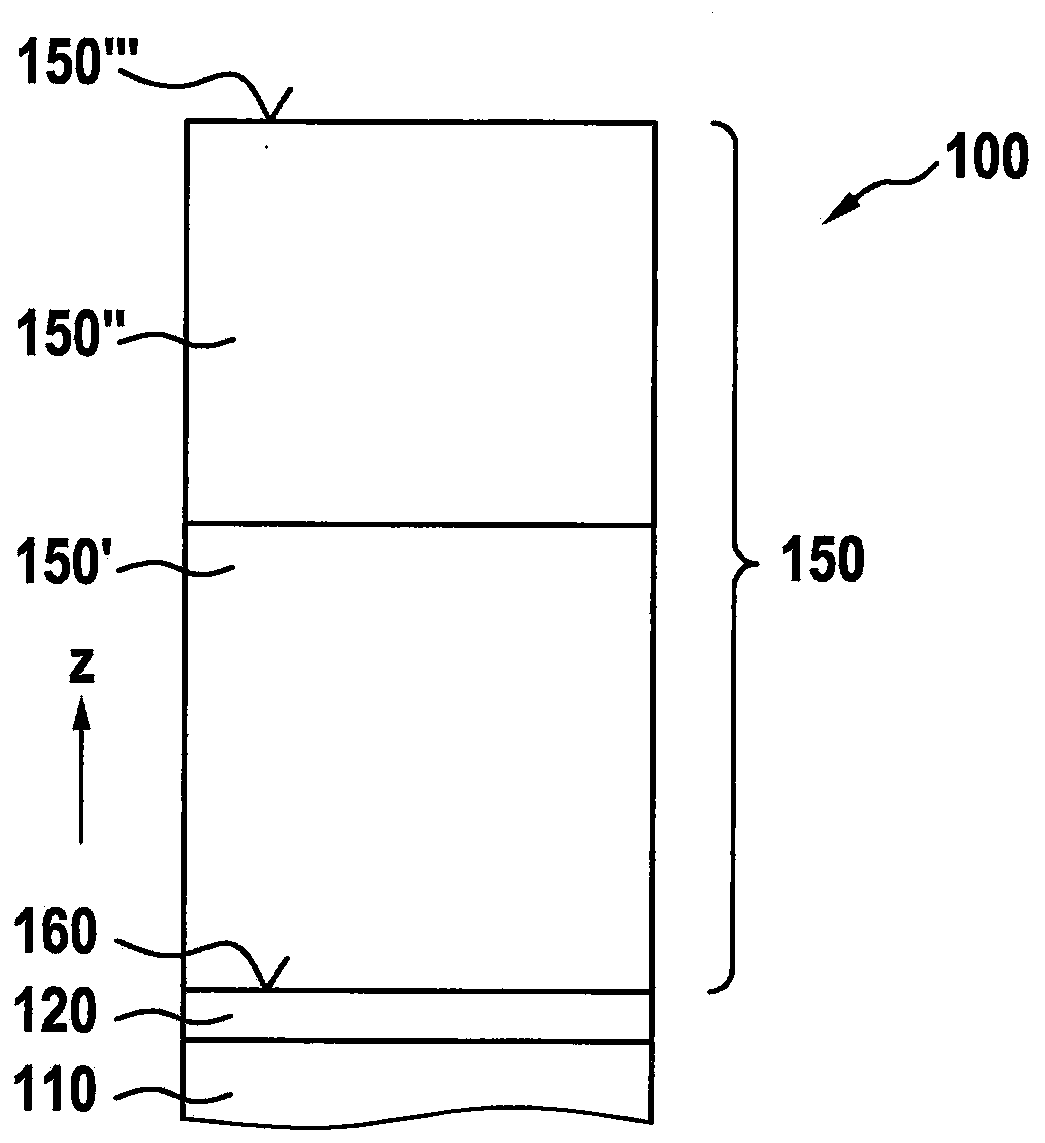

[0018] Figure 1A Shown is a strongly simplified cross-sectional view of a wear protection layer assembly 10 according to the invention, which successively consists of a substrate 11 , an adhesive layer 12 applied to the substrate 11 , a first transition layer 13 , a second The transition layer 14 is formed by a final protective or functional layer 15 . Here, a component generally composed of steel is used as substrate 11 , which component is provided for coating in order to improve the wear resistance and heat resistance of the component. The adhesive layer 12 applied to the substrate 11 consists of crystalline chromium, while the two transition layers 13 , 14 applied to this adhesive layer are formed as chromium carbide compounds and differ from each other mainly with respect to the chromium / carbon ratio. , in order to produce a microscopic adaptation to the functional layer 15 subsequently applied on said transition layer. The outwardly terminating functional layer 15 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com