Method for producing a housing for an electronic system

A technology for electronic devices and housings, which is applied in the field of manufacturing housings for electronic devices, achieves the effects of improving sealing, preventing thermal effects, and simplifying thermal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

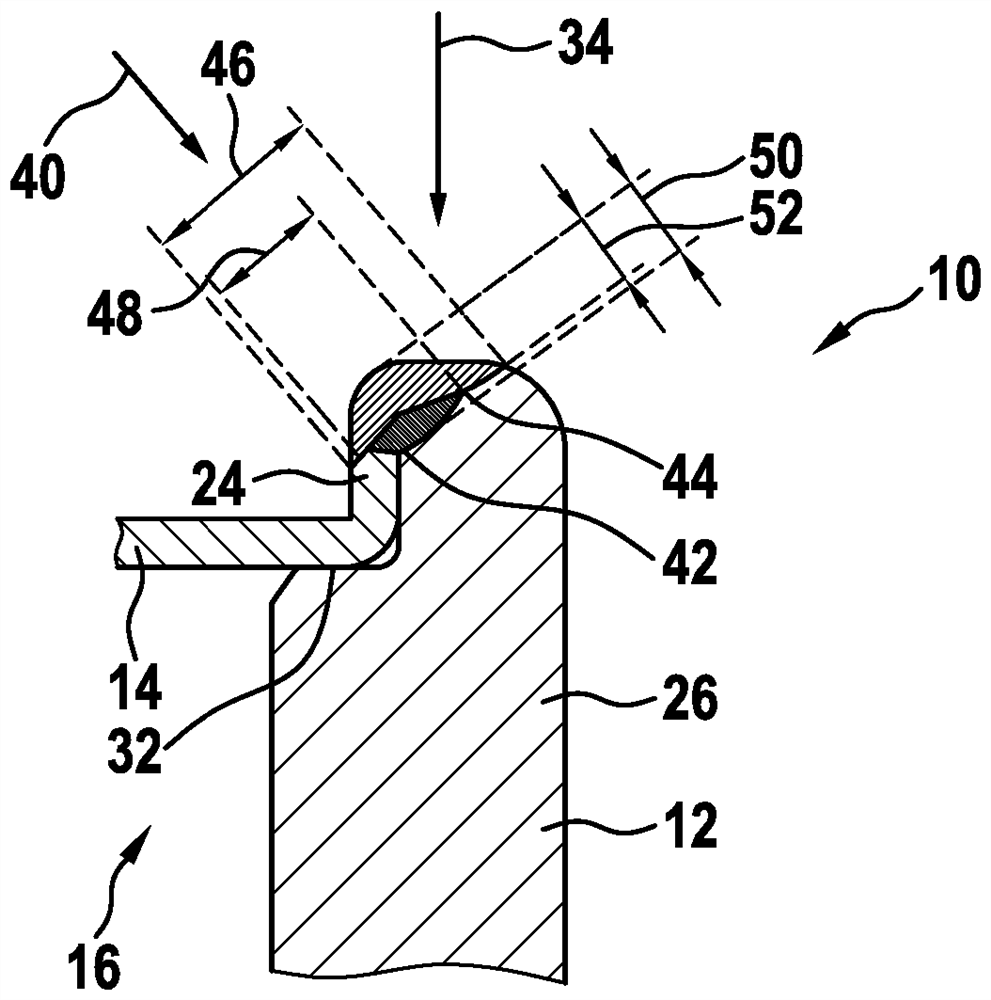

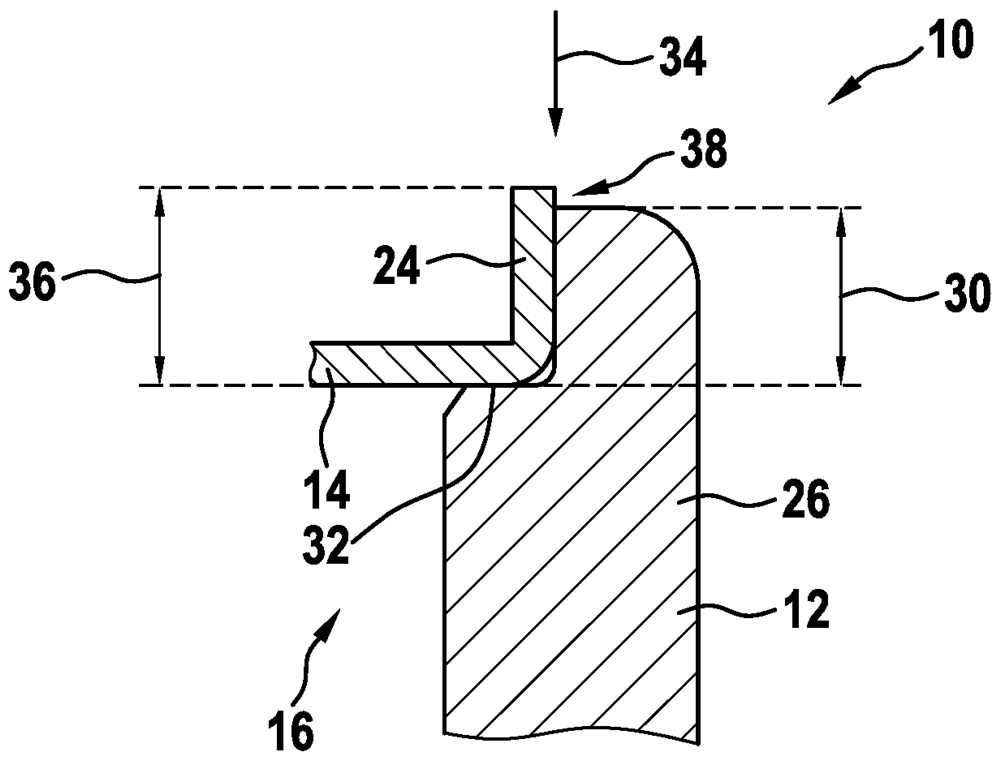

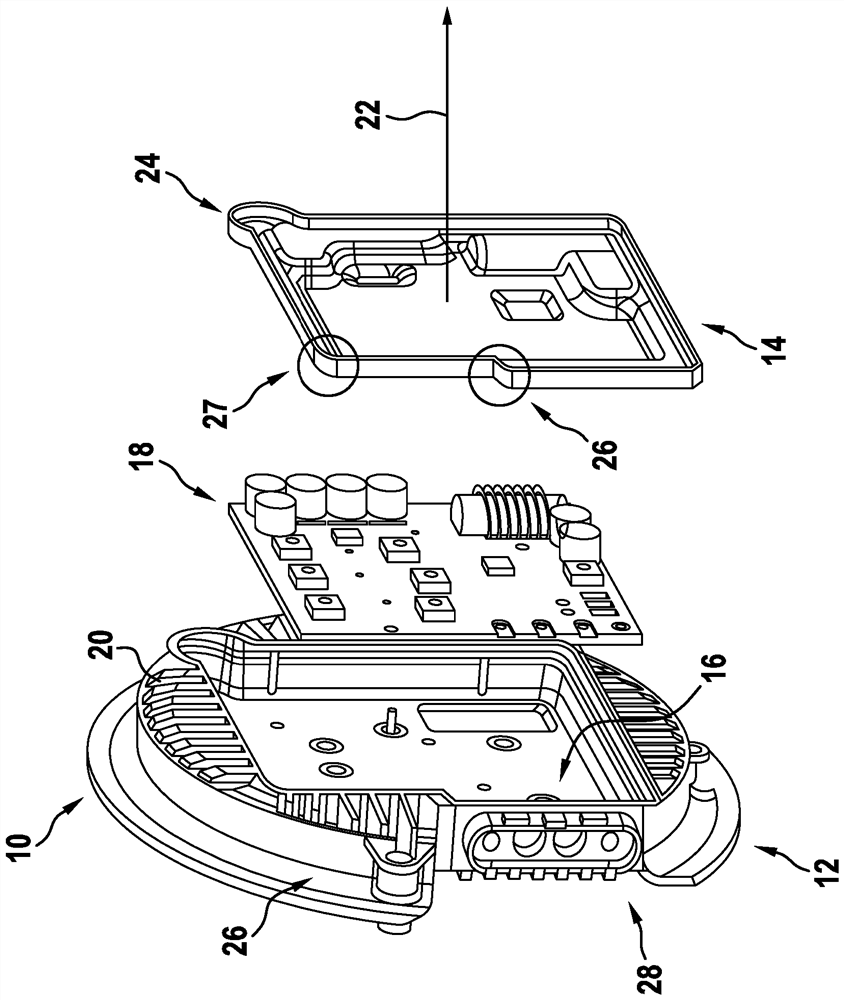

[0029] exist figure 1 An exploded view of the housing 10 according to the invention is shown in . The housing 10 comprises a first housing element 12 and a second housing element 14 . exist figure 1 The housing 10 shown in is adapted to house electronics 18 for controlling the electric motor. However, it should be expressly mentioned here that applications for such a housing 10 are also conceivable, as long as a fluid-tightly sealed housing interior is required for these applications. as in figure 1 As can be clearly seen in FIG. 1 , the first housing element 12 has a recess 16 in which an electronic component 18 is arranged in the installed state. The recess 16 has a substantially rectangular shape corresponding to the contour of the electronic component 18 . According to the invention it is provided that the housing elements 12 , 14 consist of aluminum or an aluminum alloy and that at least one of the housing elements 12 , 14 is produced by means of a die-casting method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com