Walking wheel assembly of thin ore bed mining machine

A traveling wheel and mining machine technology, which is applied in the direction of wheels, casters, wheels, etc., which are characterized by track traveling parts, can solve the problems of high time and spare parts loss, and the inability to accurately predict the amount of wear and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

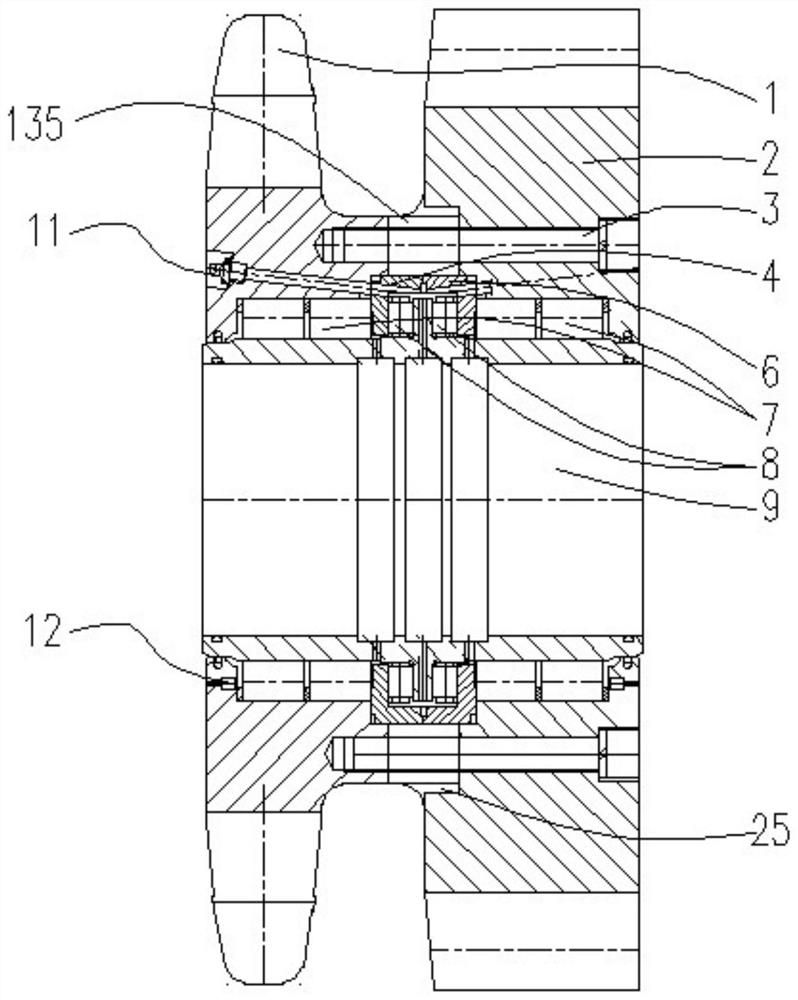

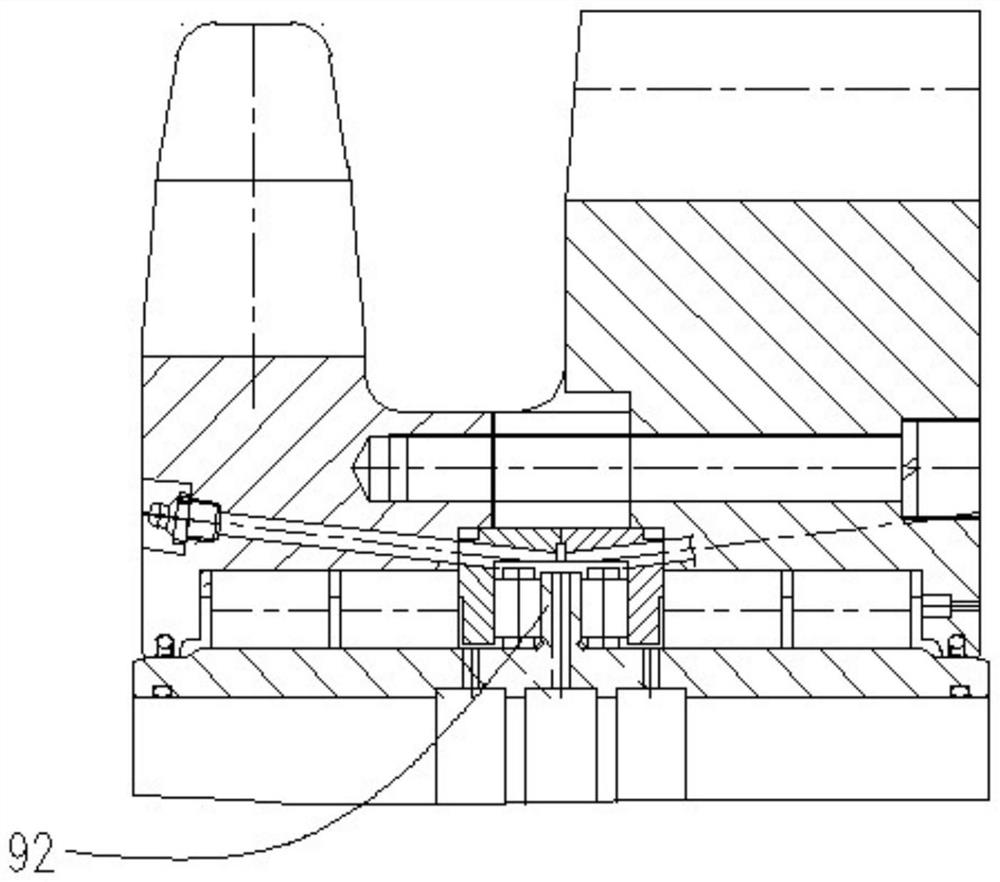

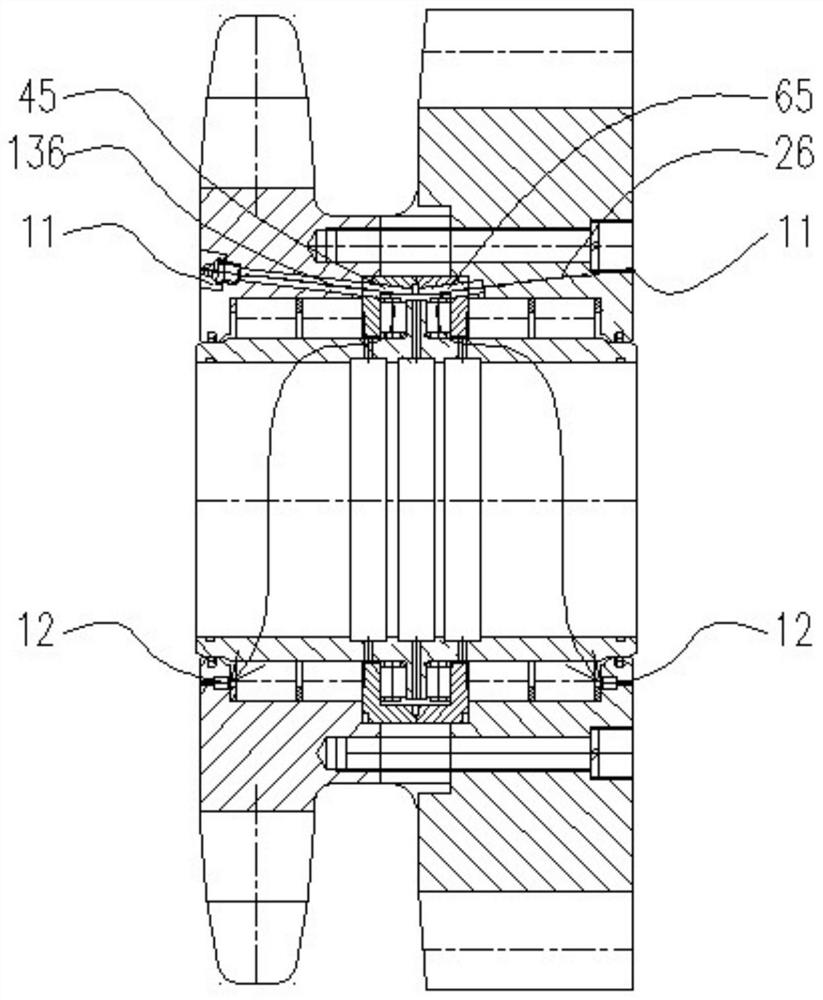

[0032] The invention discloses a walking wheel assembly of a thin seam mining machine, such as Figure 1-4As shown, it includes a shaft sleeve 9 and a road wheel 1 and a large gear 2 respectively sleeved on the left and right parts of the shaft sleeve. The road wheel is in contact with the large gear left and right and is fixedly connected, for example, it can be fixed by passing through the screw 3 in the axial direction. The inner hole of the walking wheel is set to a stepped hole with a small left and a large right, and the inner hole of the gear wheel is set to a small stepped hole with a small right and a large left. A left roller set is arranged between the smaller inner hole section of the traveling wheel and the bushing, and the smaller inner hole section of the traveling wheel and the left journal of the bushing provide an outer raceway and an inner raceway for the left roller set respectively. A right roller set is arranged between the smaller inner hole section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com