Compact traveling wheel set of thin seam mining machine

A technology for traveling wheels and shearers, which is applied in the directions of wheels, casters, wheels, etc., which are characterized by track traveling components, can solve problems such as affecting coal output, loss, and damage to traveling wheel components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

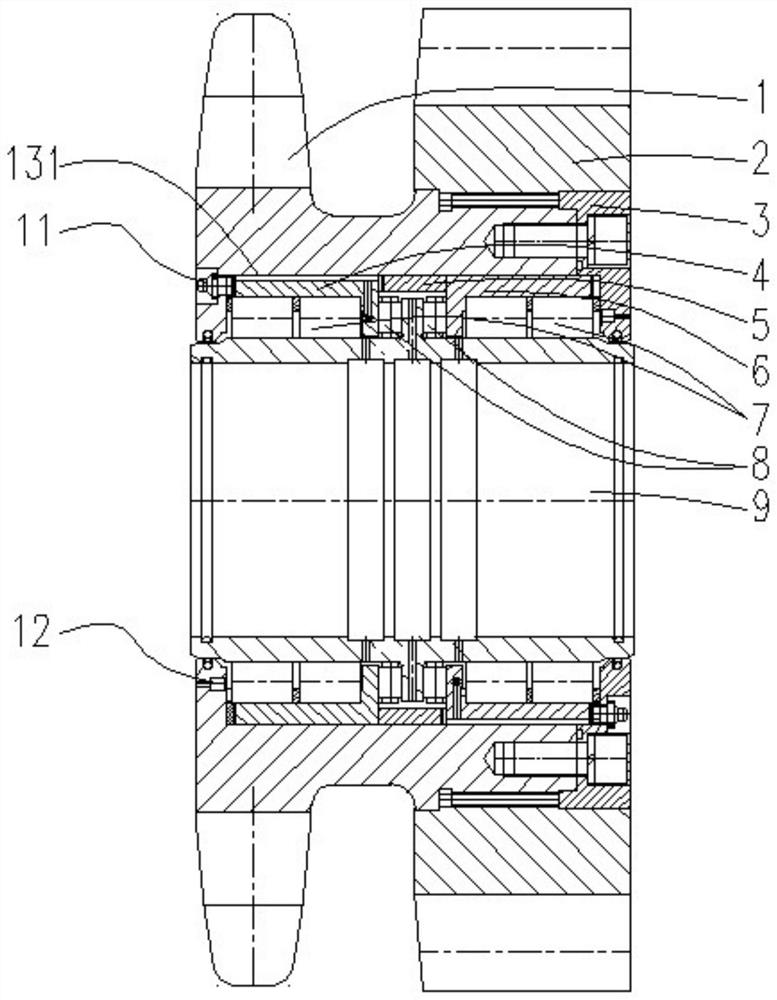

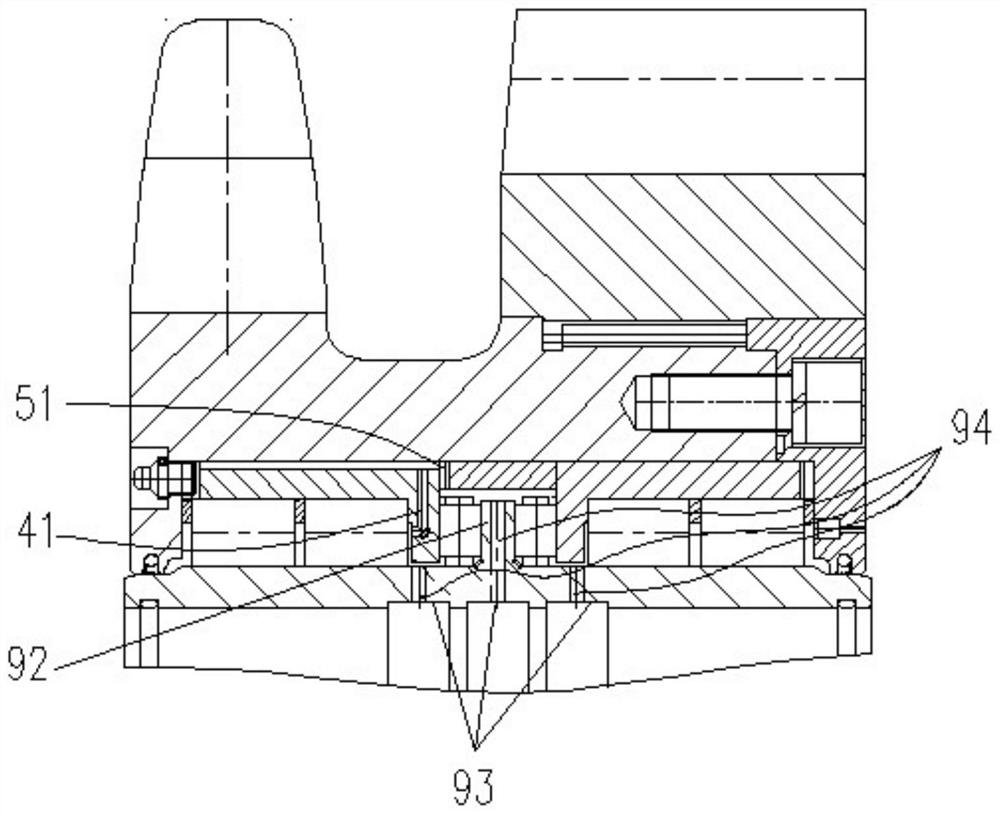

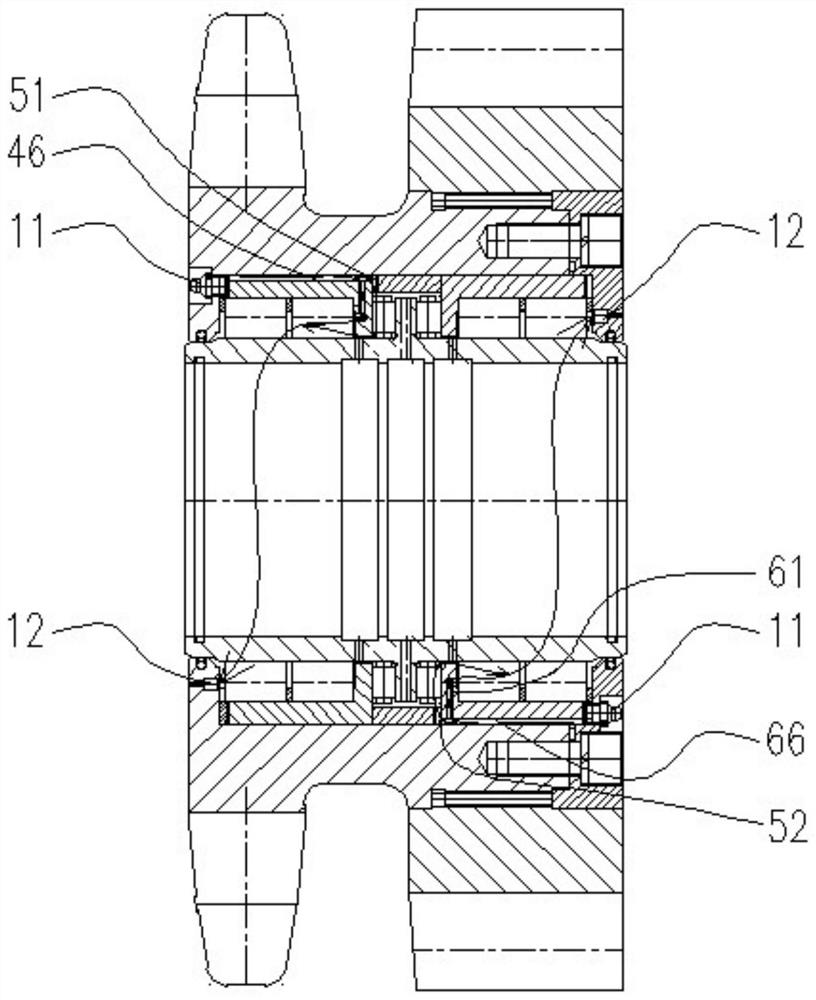

[0034] The invention discloses a compact walking wheel set of a thin coal seam shearer, such as Figure 1-6As shown, it includes a road wheel 1 and a shaft sleeve 9, the road wheel is sleeved on the shaft sleeve, and a left roller assembly, two rows of axially stressed bearings 8 (including thrust Bearings and radial bearings that can withstand a certain axial load) and right roller assemblies. The right end of axle sleeve is covered with gland 3, and gland is fixedly connected with traveling wheel, for example can be fixed by screw, and rotary seal is set between gland and axle sleeve. The gland axially locates the right roller assembly. The left roller assembly is positioned axially by sheathing an end cover at the left end of the shaft sleeve or setting a rib integrated with the road wheel at the left end of the left roller assembly (this is the case in the embodiment shown in the drawings). A rotary seal is provided between the end cover or rib and the shaft sleeve. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com