Early fault analysis and feature extraction method for equipment vibration signal under variable speed working condition

A vibration signal and early failure technology, applied in equipment failure analysis, predictive maintenance and fault diagnosis, and monitoring of the condition of rotating equipment in the nuclear power industry production site, can solve the problem of poor application effect of resonance demodulation technology and complex equipment operating conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

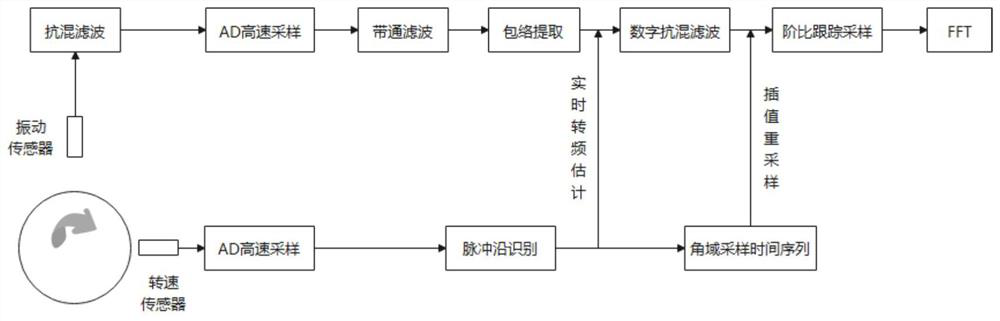

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

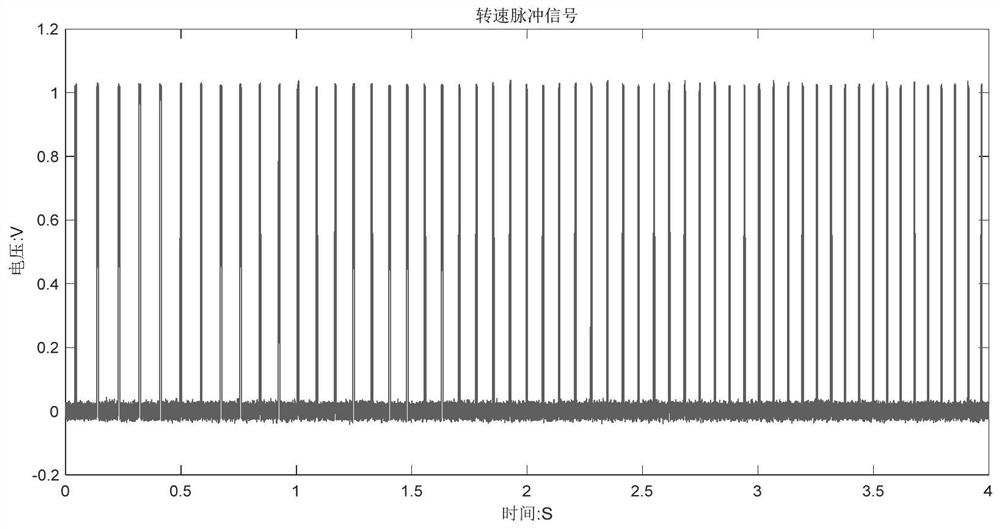

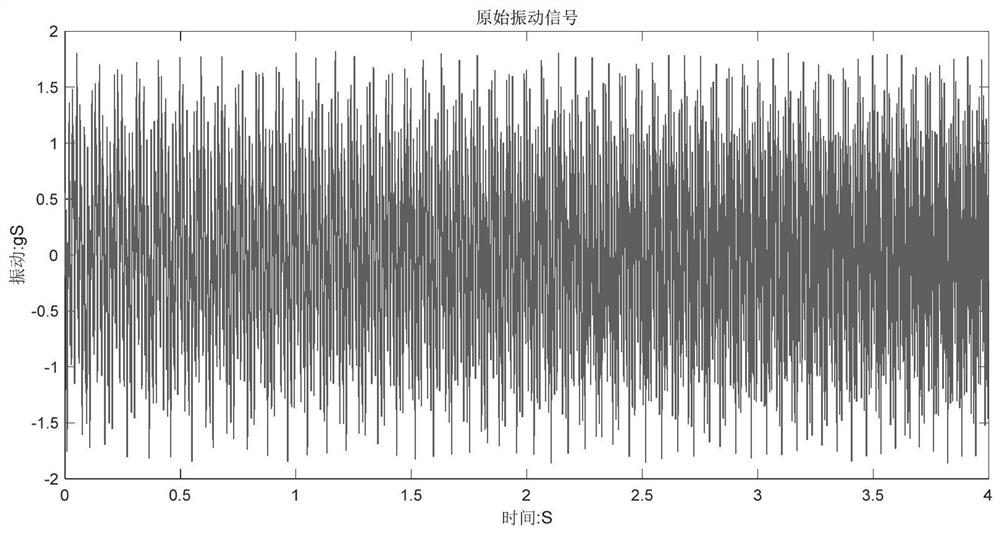

[0029] 1) Select the 8-channel 24-bit synchronous acquisition module ADS1278 from TI Company to perform high-speed synchronous acquisition of the vibration signals of rotating equipment such as bearings and gearboxes and the rotational speed signals of the rotating shaft. The vibration sensor selects the IEPE piezoelectric ceramic acceleration sensor, and the rotational speed sensor selects the inductive approach switch, the sampling frequency is set to 256kps, and the vibration signal is anti-aliased by using an 8th-order Chebyshev filter before the vibration signal is collected to filter out high-frequency noise and useless high-frequency signals, and the filter cutoff is set to 12.8kHz. Vibration signals acquired synchronously c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com