Building material hardness detection equipment

A technology for testing equipment and building materials, applied in the direction of testing material hardness, analyzing materials, measuring devices, etc., can solve problems such as damage to testing equipment and high pressure of testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below in connection with the embodiments and drawings. Here, a schematic embodiment of the present invention will be described herein for explanation of the invention, but is not limited to the present invention.

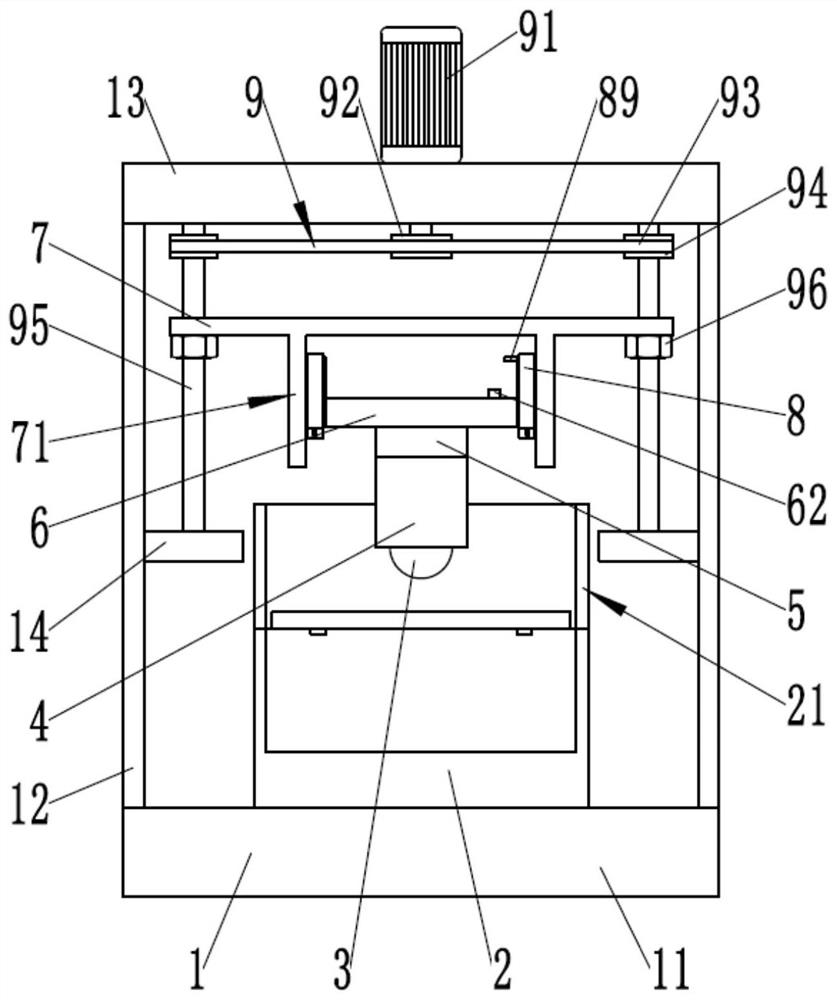

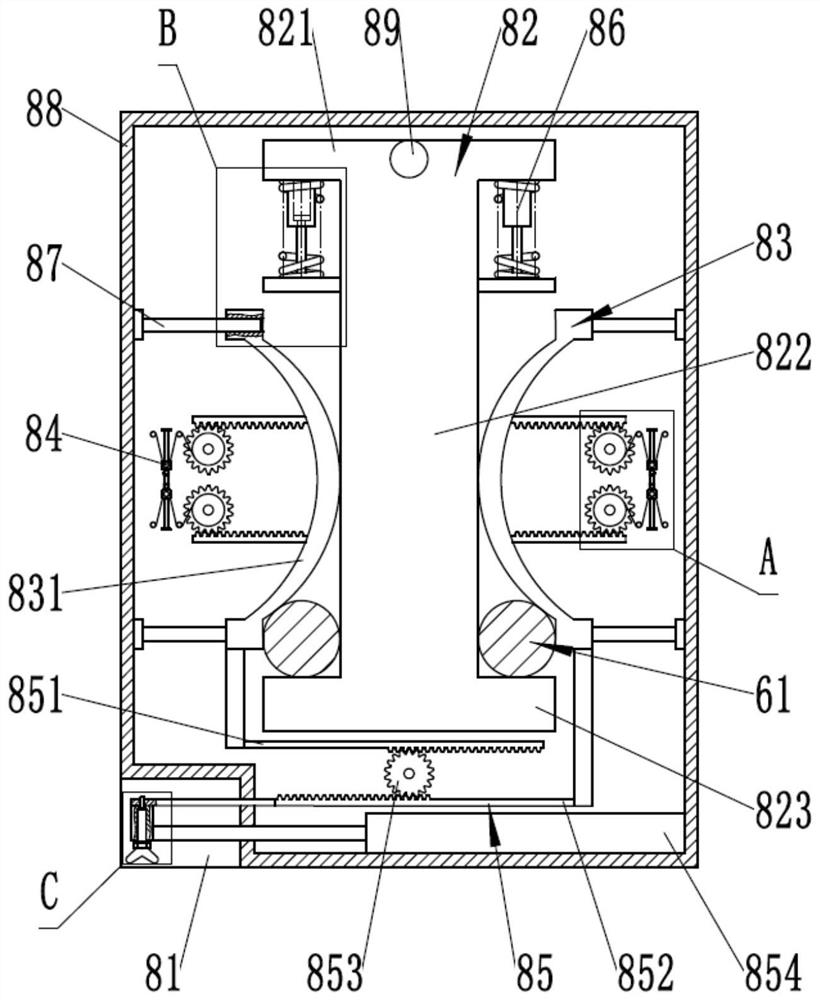

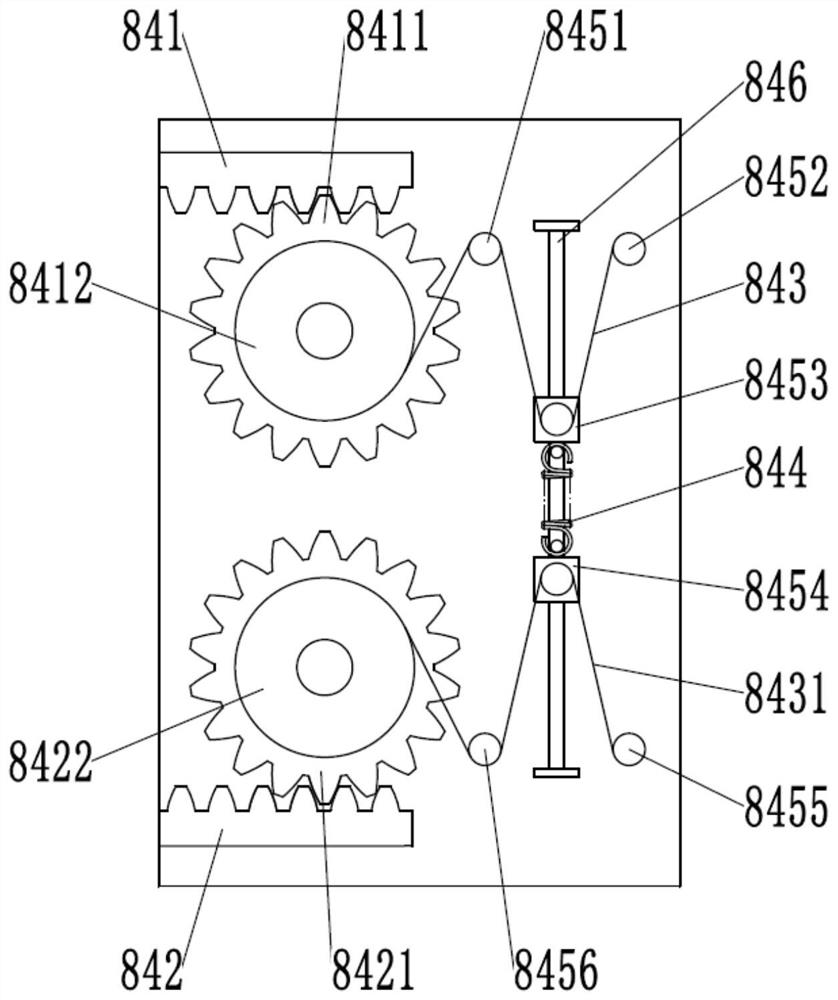

[0023]referenceFigure 1 to 5,Such asfigure 1 A building material hardness detecting device, including a frame 1, a table 2, a mounting frame 6, a lifting frame 7, and a lifting mechanism 9, and the frame 1 includes a base 11, a top plate 13 and a connection disposed above the base 11. A pair of side panels 12 between the top plate 13 and the base 11, each of which is provided with a panel 14, and the table 2 is disposed on the base 11 of the frame 1, and the lifting mechanism 9 is disposed. The rack 1 is provided with an overload protection mechanism 8 on the one pair of vertical plate portions 71 of the lower portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com