Hydrophobic carbon quantum dot mofs composite adsorbent and preparation method thereof

A composite adsorption and carbon quantum dot technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of reducing MOFs adsorption of VOCs and MOFs skeleton collapse, so as to increase the proportion of micropore area and improve hydrophobicity , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

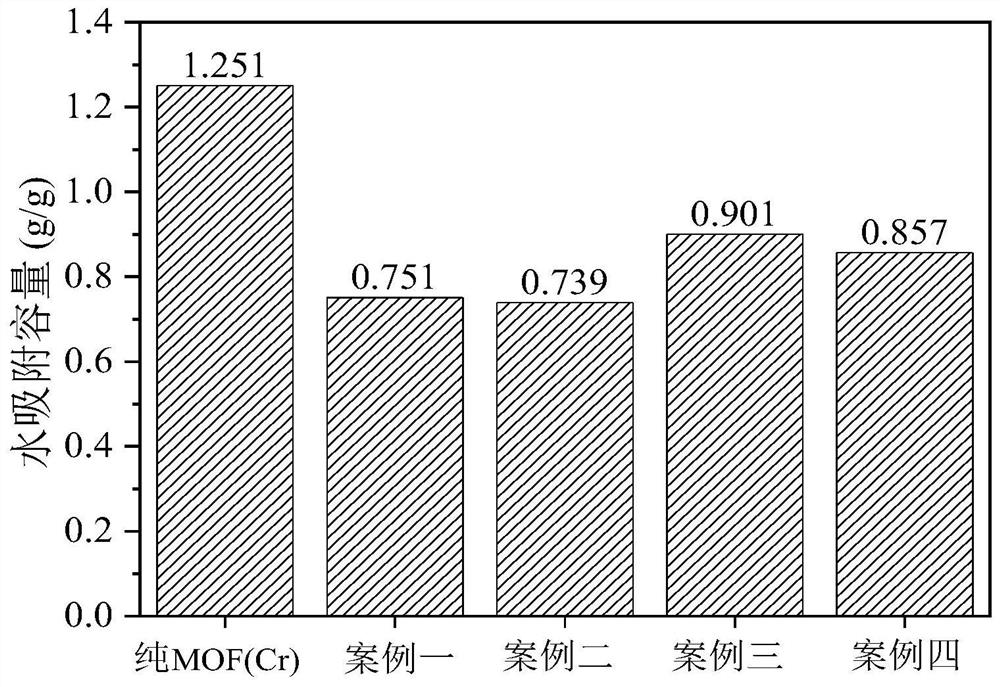

Embodiment 1

[0037] A kind of hydrophobic carbon quantum dot MOFs composite adsorbent and preparation method thereof, comprising the following steps,

[0038] (1) 0.05mol CrNO 3 9H 2 0 and 0.005mol citric acid monohydrate were uniformly dispersed in 25mL ultrapure water to obtain solution A;

[0039] (2) Then slowly add 0.05mol terephthalic acid into solution A, and stir for 40 minutes to obtain solution B;

[0040] (3) After solution B is added dropwise the aqueous solution containing 0.002mol hydrogen fluoride, it is transferred to the reactor, rinses the beaker with four milliliters of water, and then carries out hydrothermal synthesis with a program temperature control box, as follows:

[0041] (a) Heating process: to 200°C at a heating rate of 1°C / min;

[0042] (b) Constant temperature process: keep at 200°C for 8 hours;

[0043] (c) Cooling process: reduce the temperature to 30-40°C at a cooling rate of 1-10°C / min.

[0044] After cooling down, transfer to a centrifuge tube, separa...

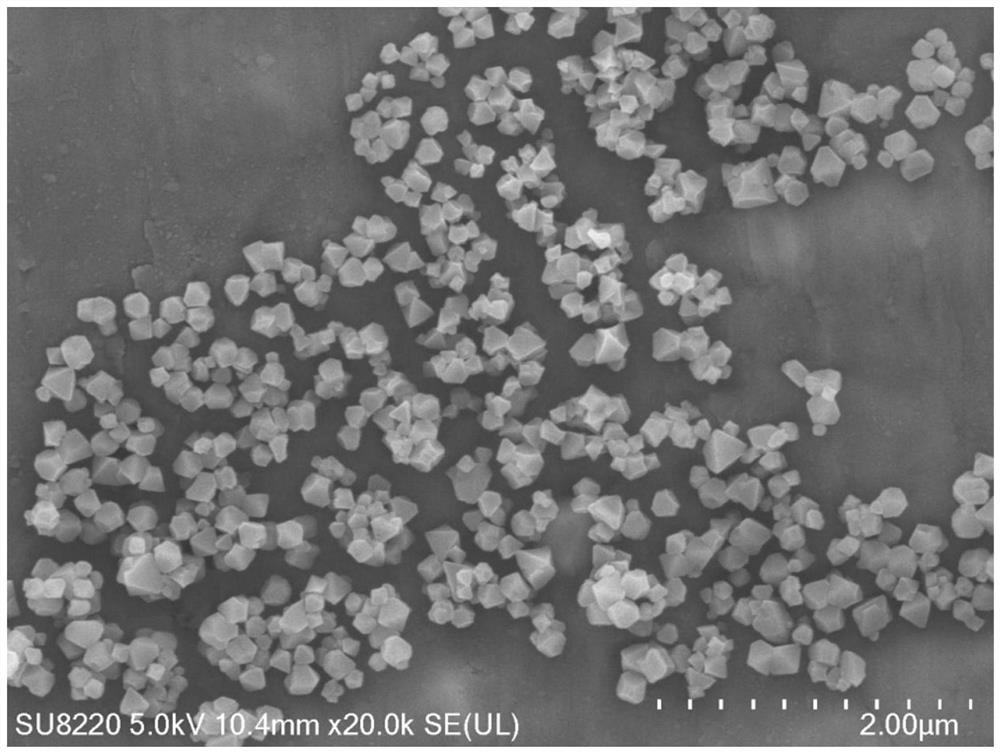

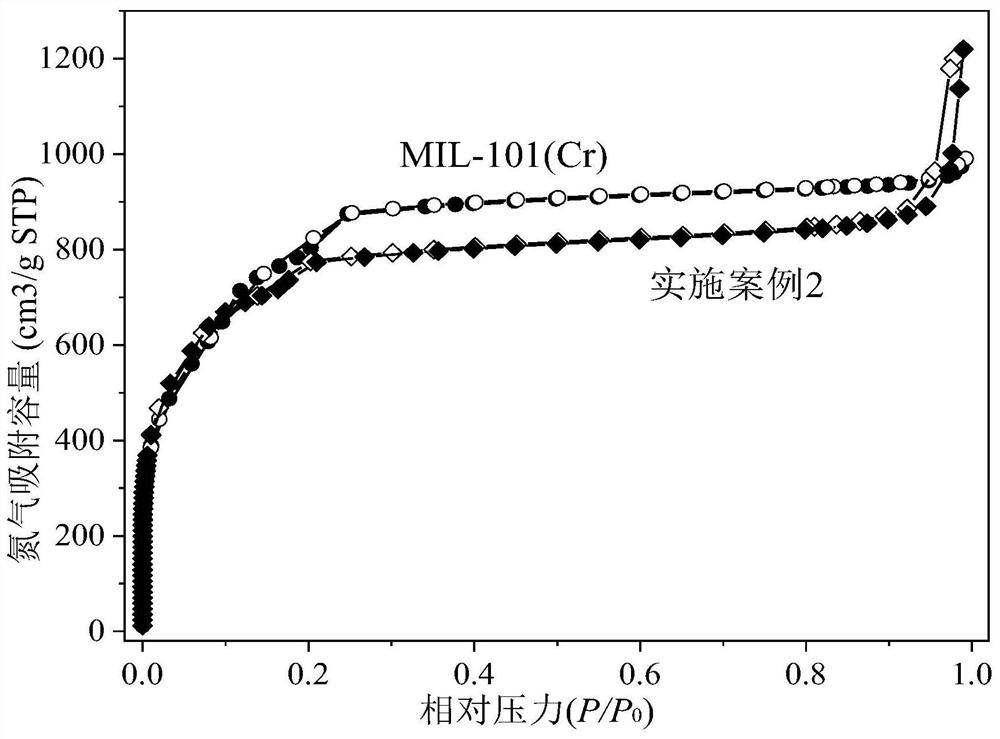

Embodiment 2

[0046] A kind of hydrophobic carbon quantum dot MOFs composite adsorbent and preparation method thereof, comprising the following steps,

[0047] (1) 0.05mol CrNO 3 9H 2 0 and 0.005mol citric acid monohydrate were uniformly dispersed in 20mL ultrapure water to obtain solution A;

[0048] (2) Then slowly add 0.05mol terephthalic acid into solution A, and stir for 30 minutes to obtain solution B;

[0049] (3) After solution B is added dropwise the aqueous solution containing 0.002mol hydrogen fluoride, it is transferred to the reactor, rinses the beaker with four milliliters of water, and then carries out hydrothermal synthesis with a program temperature control box, as follows:

[0050] (a) Heating process: to 220°C at a heating rate of 1°C / min;

[0051] (b) Constant temperature process: keep at 220°C for 8 hours;

[0052] (c) Cooling process: drop to 30°C at a cooling rate of 1°C / min.

[0053] After cooling down, transfer to a centrifuge tube, separate the supernatant aft...

Embodiment 3

[0055] A kind of hydrophobic carbon quantum dot MOFs composite adsorbent and preparation method thereof, comprising the following steps,

[0056] (1) 0.05mol CrNO 3 9H 2 0 and 0.01mol citric acid monohydrate were uniformly dispersed in 45ml ultrapure water to obtain solution A;

[0057] (2) Then slowly add 0.05mol terephthalic acid into solution A, and stir for 60 minutes to obtain solution B;

[0058] (3) After solution B is dripped with an aqueous solution containing 0.006mol hydrogen fluoride, it is transferred to the reactor, and then the hydrothermal synthesis is carried out with a program temperature control box, as follows:

[0059] (a) Heating process: to 210°C at a heating rate of 5°C / min;

[0060] (b) Constant temperature process: keep at 210°C for 8 hours;

[0061] (c) Cooling process: drop to 40°C at a cooling rate of 5°C / min.

[0062] After cooling down, transfer to a centrifuge tube, separate the supernatant after centrifugation, add DMF to wash, recirculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com