Spring string feeding device and spring string conveying mode thereof

A conveying method and a technology of spring strings, which are applied in the manufacture of springs from wires, other household appliances, applications, etc., can solve problems such as large spacing between clamping conveyor belts, spring strings falling, and failure to transport normally, so as to avoid positional misalignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

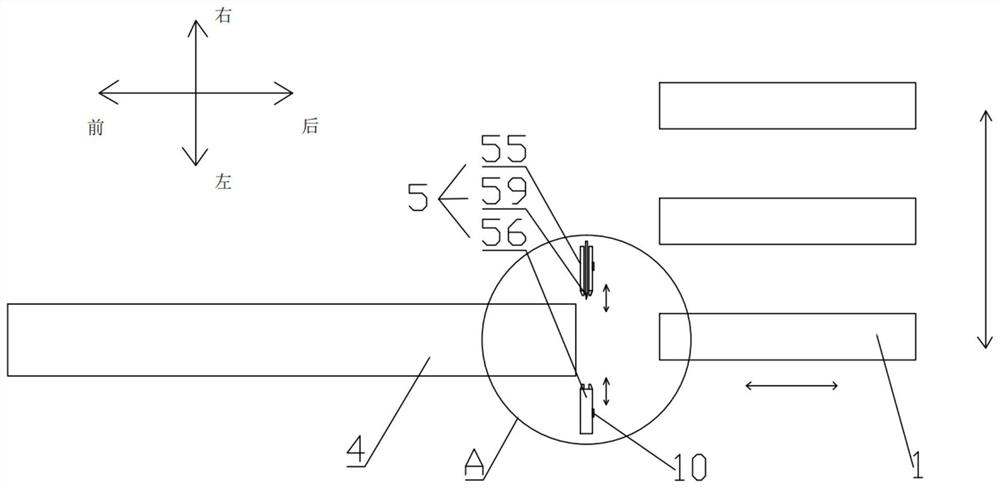

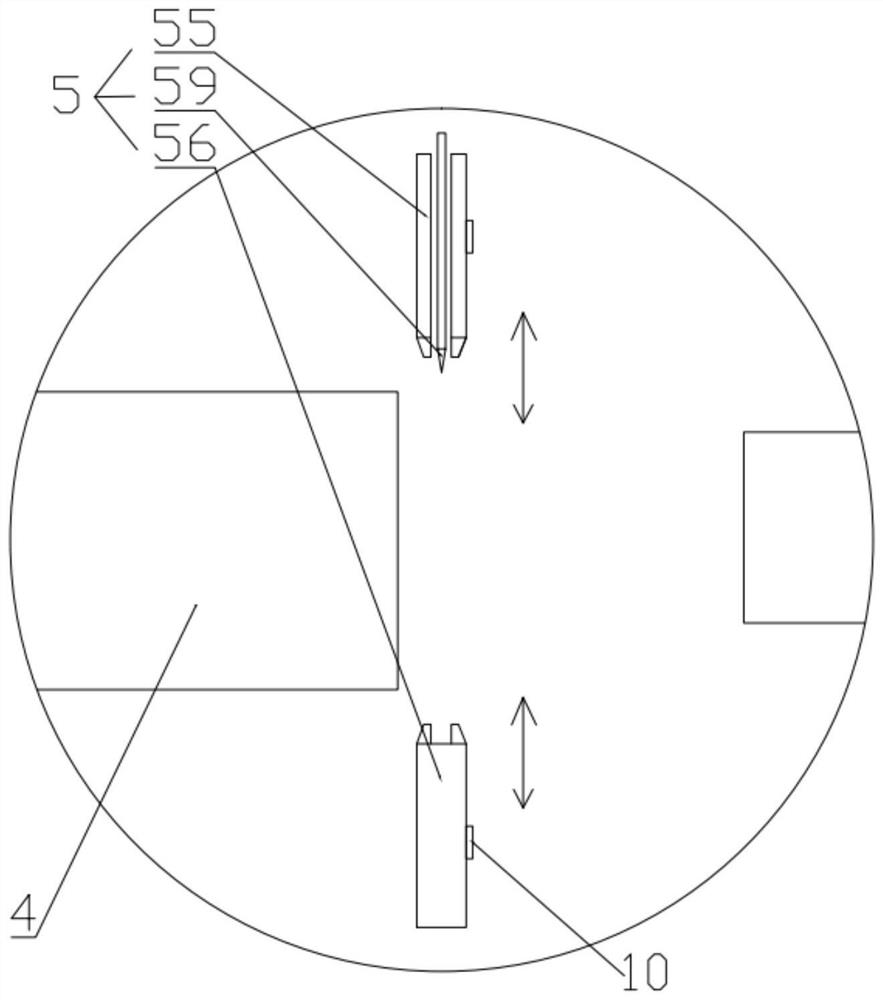

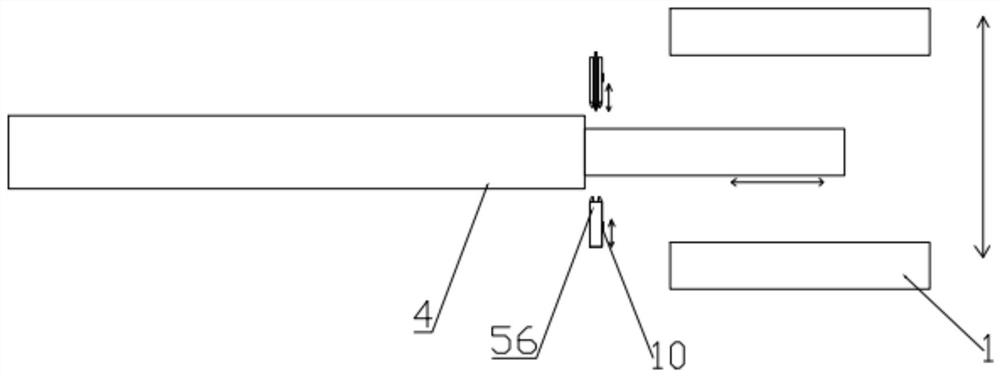

[0044] Such as Figure 1-11 Shown is a spring string feeding device of the present invention, comprising a first conveying mechanism 1, a second conveying mechanism 4 and a welding and cutting mechanism 5;

[0045] The first conveying mechanism 1 and the second conveying mechanism 4 are sequentially arranged along the front-to-back direction, and the first conveying mechanism 1 and the second conveying mechanism 4 are clamping conveying devices arranged up and down. The first conveying mechanism 1 and the The second conveying mechanism 4 can be opened and closed up and down, and more than two first conveying mechanisms 1 are arranged in parallel along the left and right directions, and all the first conveying mechanisms 1 move left and right synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com