A kind of preparation method of micro-branched titanium-based polyester melt direct-spun poy filament

A titanium-based polyester, melt direct spinning technology, applied in the field of polyester, can solve the problems of poor homogeneity of polyester melt, improve uniform distribution, improve spinning efficiency and filament quality, improve melt viscosity drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of microbranched titanium-based polyester melt direct-spun POY filament, comprising the following steps:

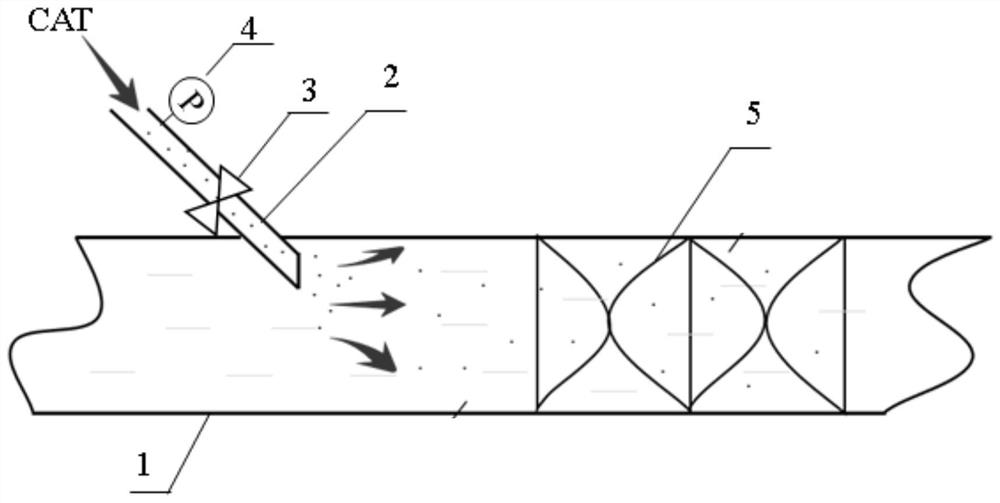

[0042](1) terephthalic acid and ethylene glycol are placed in a container in a mass ratio of 1:0.43-0.52, and the branching agent accounting for 30-150 ppm of polyester quality and 20-50 ppm of polyester quality are added successively into the container. The cocatalyst is prepared into slurry; the above slurry is poured into an esterification kettle that accounts for 5-30ppm of polyester mass to carry out esterification reaction, temperature is 260-270℃, pressure is 100-700KPa, reaction time is 3-5h; esterification After the end, inject a titanium-based catalyst to obtain a mixed ester compound; the injection method is: the catalyst is injected into the ester compound line 1 from the spray gun 2, and the angle between the spray gun 2 and the ester compound line 1 is 45°; the flow direction of the catalyst solution at the spray gun outlet and the...

Embodiment 1

[0053] A preparation method of micro-branched titanium-based polyester melt direct-spun POY filament, comprising the following steps:

[0054] (1) terephthalic acid and ethylene glycol are placed in a container as 1:0.48 by mass ratio, and in the container, add the branching agent sorbitol that accounts for 80ppm of polyester quality and the promoter magnesium acetate that accounts for 35ppm of polyester quality Prepare a slurry; inject the above slurry into an esterification kettle with a mass of 20 ppm of polyester for esterification reaction, temperature 265°C, pressure 350KPa a, reaction time 4h; after esterification, inject titanium-based catalyst ethylene glycol titanium, The mixed ester compound is obtained; the injection mode is: the catalyst is injected into the ester compound pipeline 1 from the spray gun 2, and the angle between the spray gun 2 and the ester compound pipeline 1 is 45°; A check valve 3 is arranged on the outside of the pipe wall, a pressure monitorin...

Embodiment 2

[0058] A preparation method of micro-branched titanium-based polyester melt direct-spun POY filament, comprising the following steps:

[0059] (1) terephthalic acid and ethylene glycol are placed in a container as 1:0.43 by mass ratio, in the container, add the branching agent pentaerythritol that accounts for 30ppm of polyester quality and the cocatalyst cobalt acetate that accounts for 50ppm of polyester quality The slurry is prepared into a slurry; the slurry is poured into an esterification kettle that accounts for 5 ppm of the polyester mass to carry out esterification reaction, the temperature is 260°C, the pressure is 700KPa a, and the reaction time is 5h; after the esterification is completed, the titanium-based catalyst titanate is injected to obtain Mixed ester compound; the injection method is: the catalyst is injected into the ester compound line 1 from the spray gun 2, and the angle between the spray gun 2 and the ester compound line 1 is 45°; the flow direction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com