Gas turbine engine

A gas turbine and engine technology, applied in gas turbine devices, liquid fuel engines, engine components, etc., can solve the problems of overall fuel combustion reduction, short intake length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

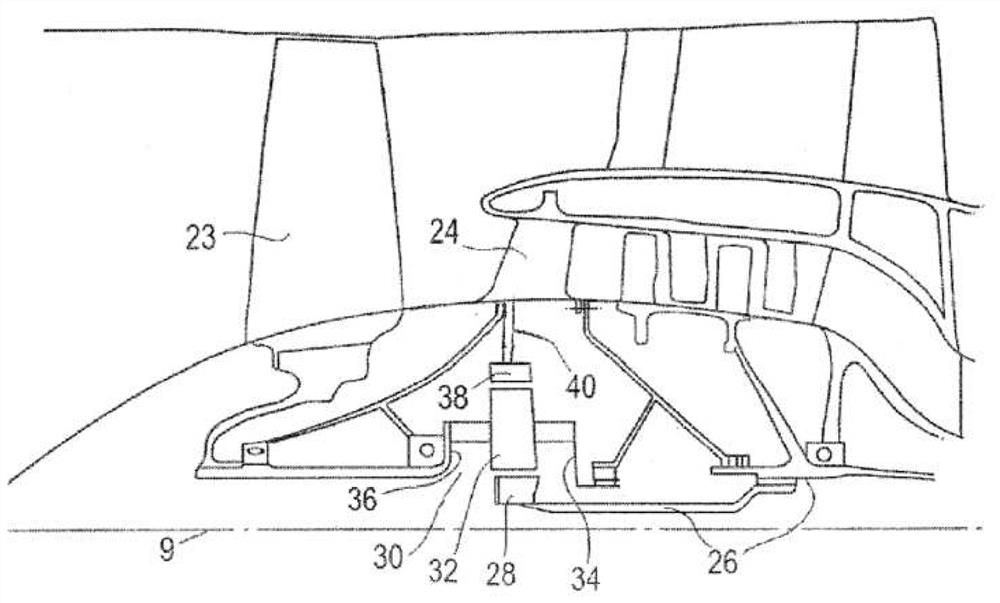

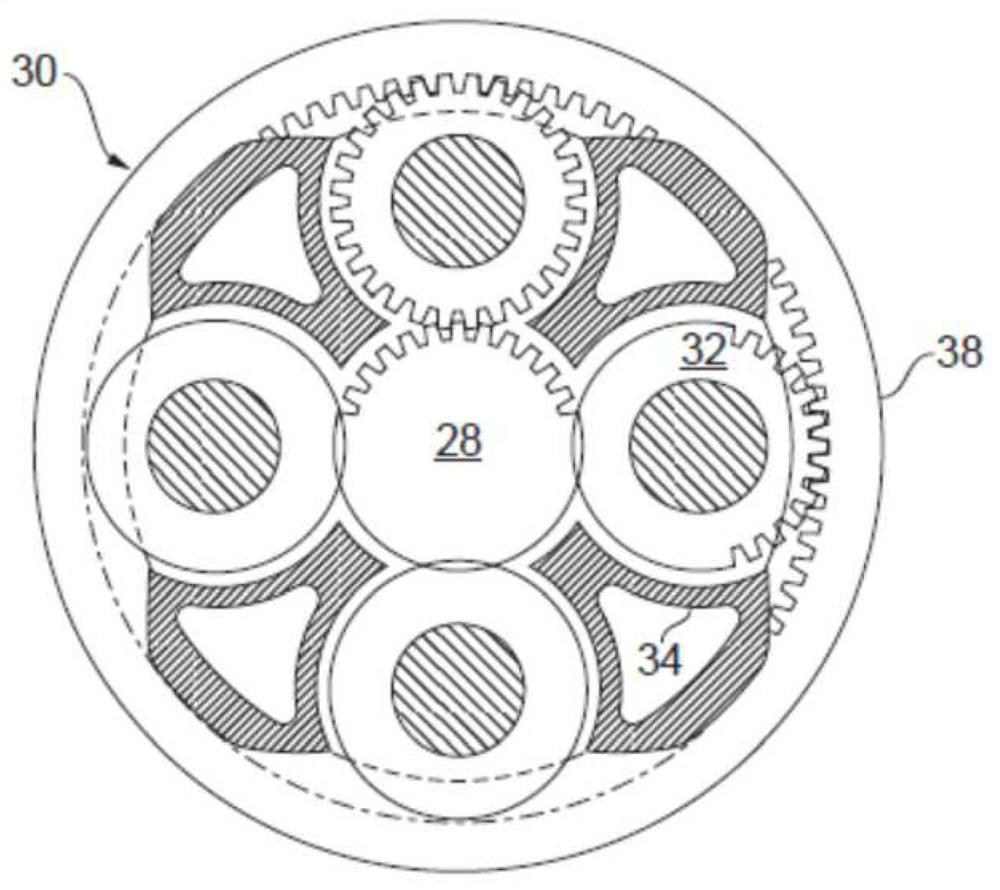

[0086] figure 1 A gas turbine engine 10 is shown having a main axis of rotation 9 . The engine 10 includes an air intake 12 and a propulsion fan 23 that generates two airflows: a core airflow A and a bypass airflow B. Gas turbine engine 10 includes a core 11 that receives a core flow A. As shown in FIG. The engine core 11 comprises a low pressure compressor 14 , a high pressure compressor 15 , a combustion device 16 , a high pressure turbine 17 , a low pressure turbine 19 and a core exhaust nozzle 20 in axial flow sequence. A nacelle 21 surrounds the gas turbine engine 10 and defines a bypass passage 22 and a bypass exhaust nozzle 18 . The bypass airflow B flows through the bypass passage 22 . The fan 23 is attached to and driven by the low pressure turbine 19 via a shaft 26 and a planetary gearbox 30 .

[0087] In use, the core gas stream A is accelerated and compressed by the low pressure compressor 14 and directed into the high pressure compressor 15 where further compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap