Backwash type stop valve

A shut-off valve and backwashing technology, which is applied in the direction of lifting valves, valve devices, valve details, etc., can solve the problem of difficult cleaning of shut-off valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0025] Embodiments of the invention are:

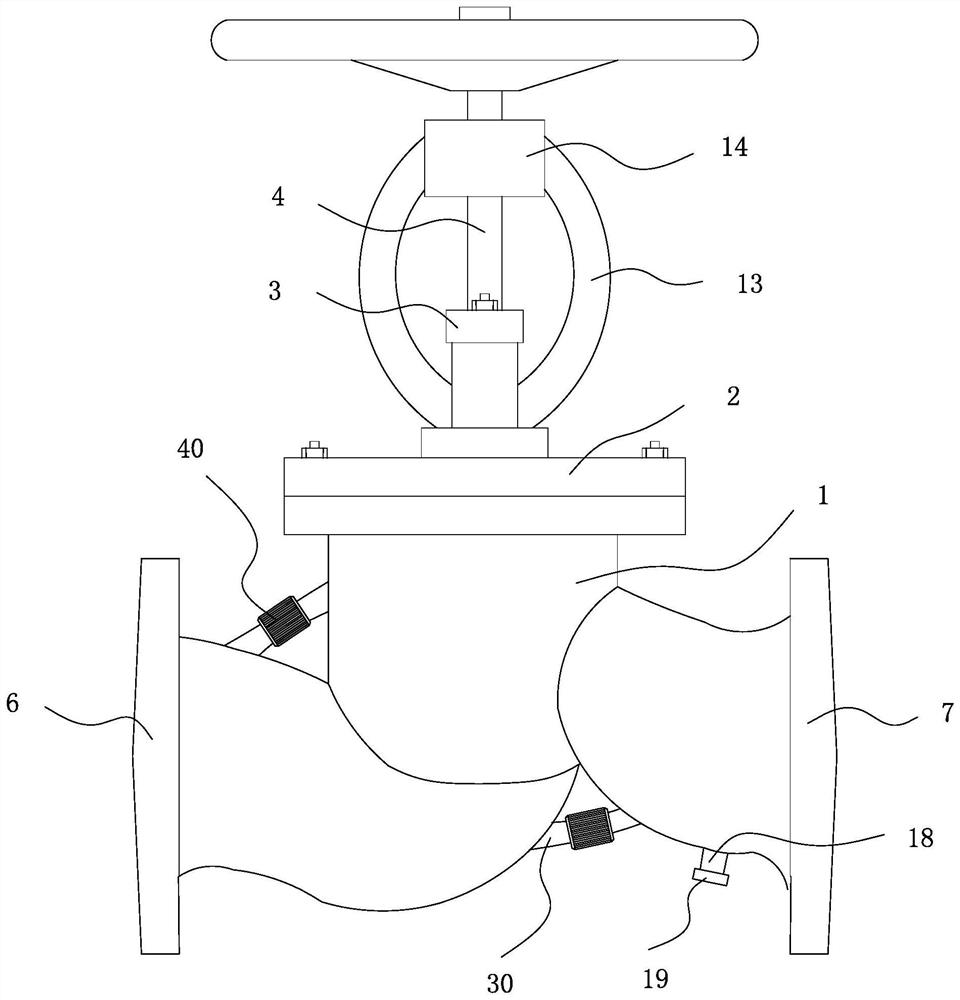

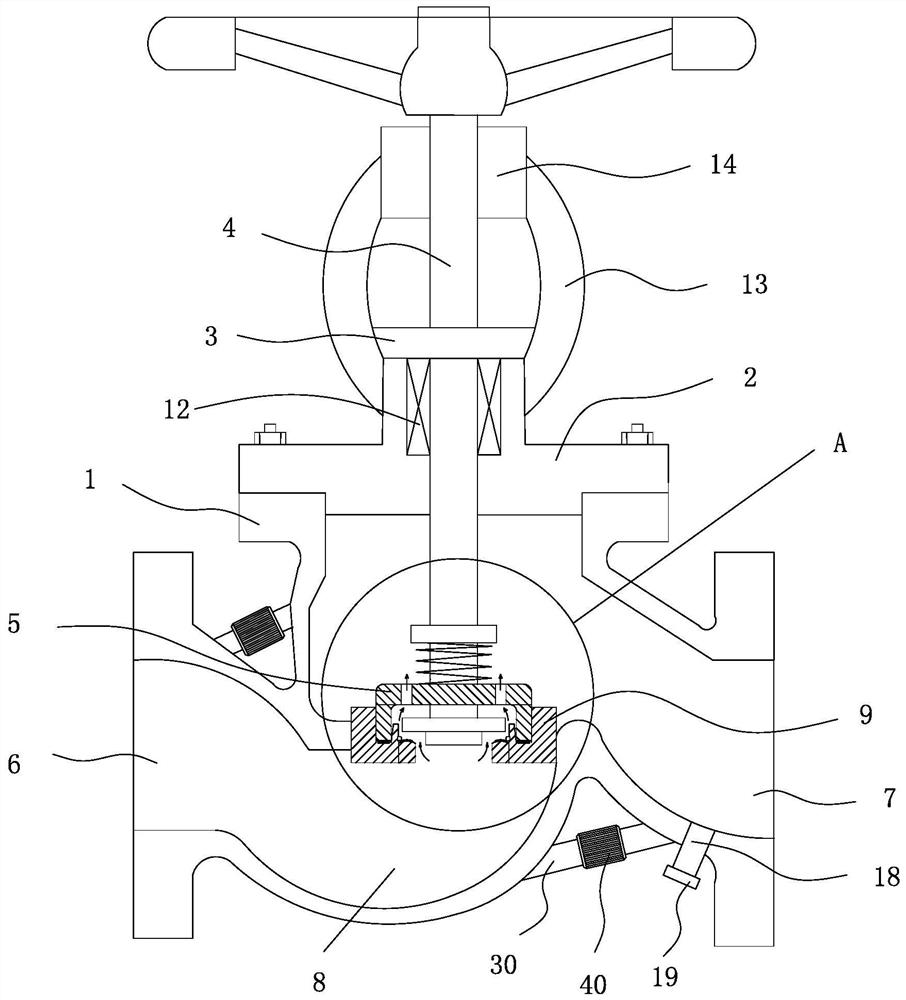

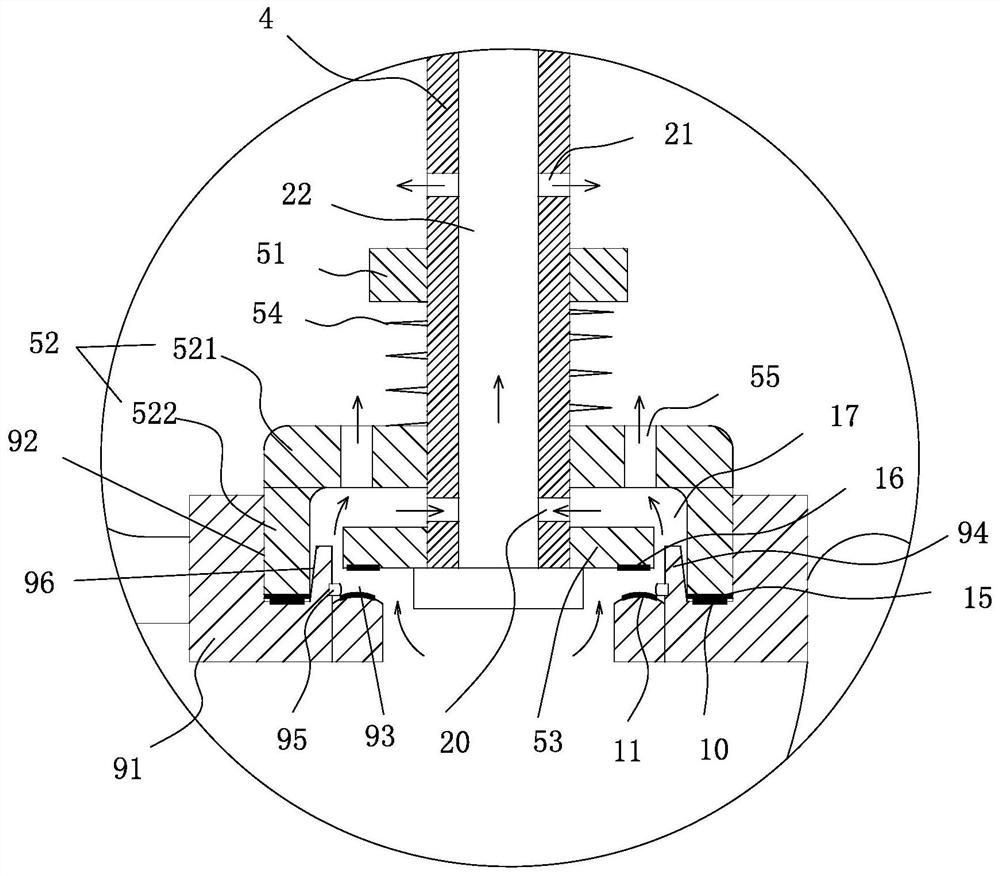

[0026] refer to Figure 1 to Figure 4 As shown, a backwash type stop valve includes a valve body 1, a valve disc cover 2, a valve cover 3, a valve stem 4, and a valve disc assembly 5. The valve body 1 has a water inlet 6, a water outlet 7 and a communication port The flow passage 8 of the water inlet 6 and the water outlet 7, the flow passage 8 is provided with a valve seat 9, and the valve seat 9 is provided with a primary sealing surface 10 and a secondary sealing surface 11, and the valve seat 9 includes a middle The valve seat body 91 whose opening communicates with the flow channel 8 is provided with a first annular groove 92 and a second annular groove 93 sequentially recessed inward along the radial direction on the valve seat body 91, so that the valve seat body 91 is located on the first A partiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com