Direct cooling ice-making system for balancing compressor load and control method thereof

A technology of compressor load and control method, applied in ice making, ice making, application, etc., can solve the problems of affecting the service life of the compressor, uneven cooling supply, small cooling load, etc., so as to improve the efficiency of ice making, prolong the The effect of long service life and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

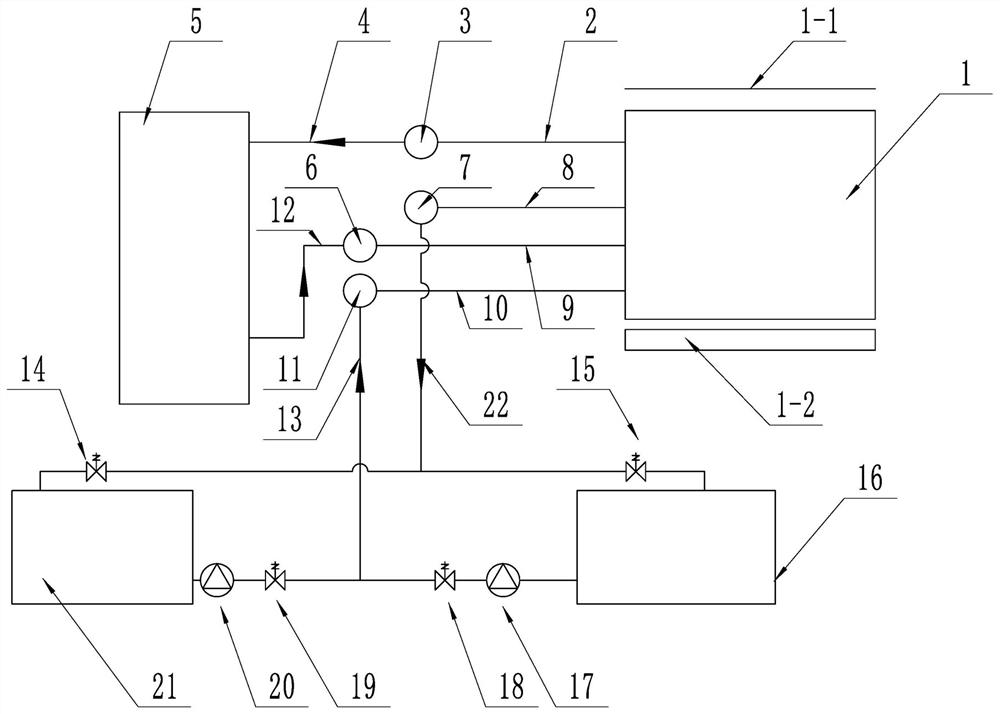

[0018] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

[0019] like figure 1 The embodiment of the direct cooling ice-making system used to balance the compressor load in the present invention includes an ice-making device 1, and the ice-making device 1 includes a set of composite ice molds, and the composite ice molds include a built-in first heat exchange tube The side panels of the ice mold, the upper cover of the ice mold and the movable bottom plate of the ice mold. The embodiment of the direct cooling ice-making system also includes a compression condensing unit 5, the compressor liquid supply pipe 12 of the compression condensing unit 5 is connected to the first refrigerant liquid supply header 6, and the first refrigerant liquid supply header 6 The liquid inlet end of the first heat exchange tube is connected through the first refrigerant liquid supply branch pipe 9, and the liquid outlet end of the first heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com