Blade micropore angle measuring method

A technology of angle measurement and small microholes, applied in the field of measurement, can solve the problems of long processing time, large error, inaccurate measurement angle, etc., and achieve the effect of improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

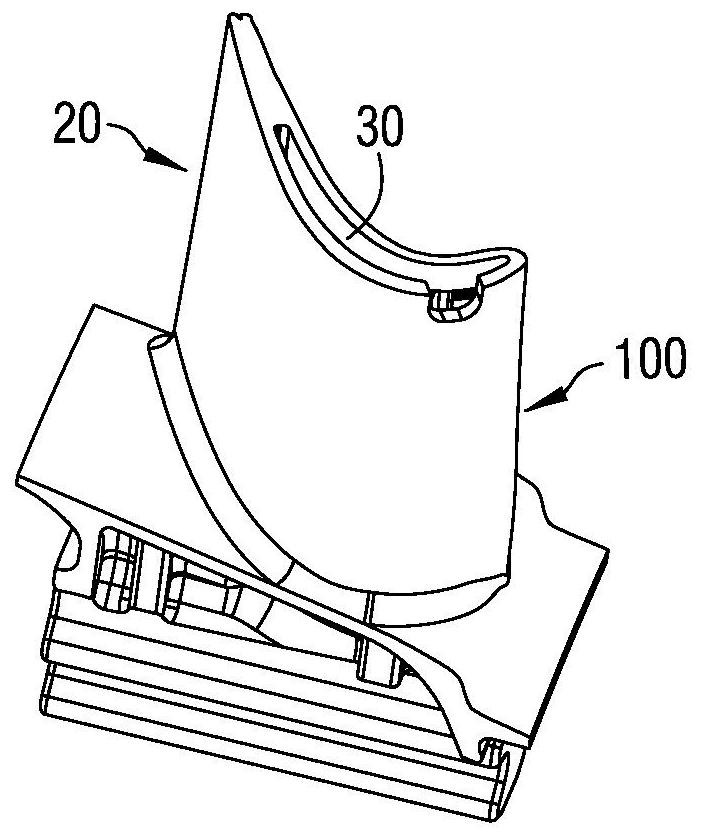

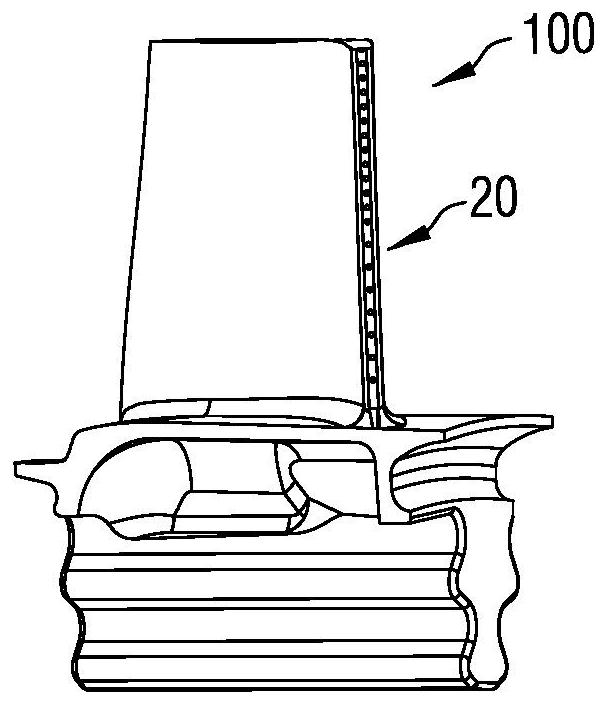

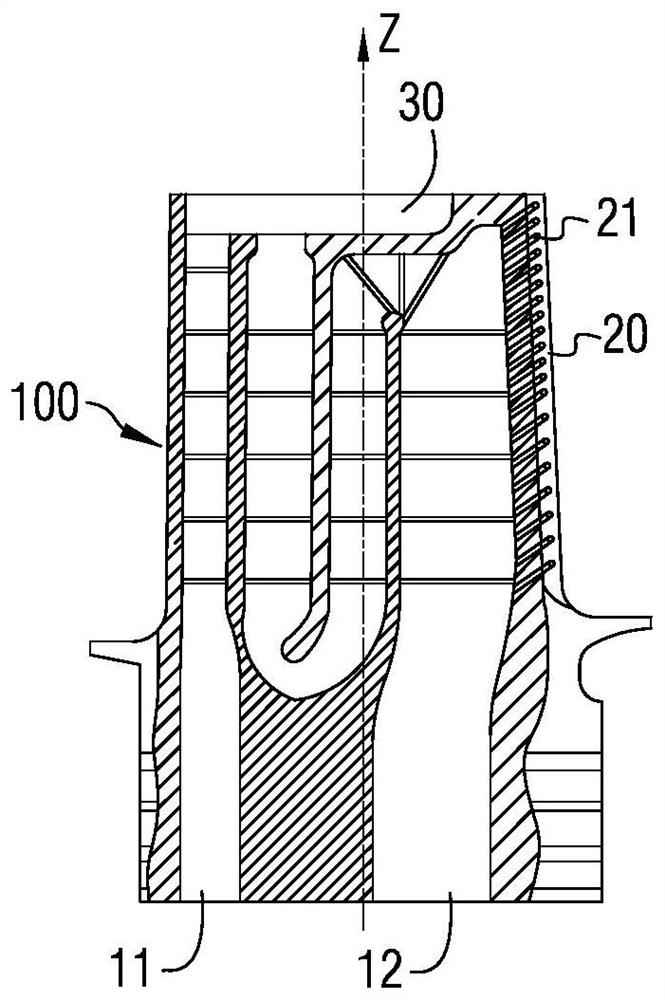

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0038] As described in the background technology, in view of the problem that the angle of the air film hole 21 cannot be directly measured because the existing hole diameter is generally between φ0.25mm~φ0.5mm, and the depth is not less than 6mm, the inventors carried out the principle After an in-depth analysis, the root cause is summarized as follows:

[0039] 1. Since the diameter of the air film hole 21 is too small, there is no existing standard measuring stick that can be inserted into it for measurement of hole angle extension.

[0040] 2. Since the diameter of the air film hole 21 is too small, and the inner cavity of the aeroengine blade 100 has complex circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com