Direct type light-emitting device

A light-emitting device, direct-type technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of uneven brightness and limited effect of direct-type backlight modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

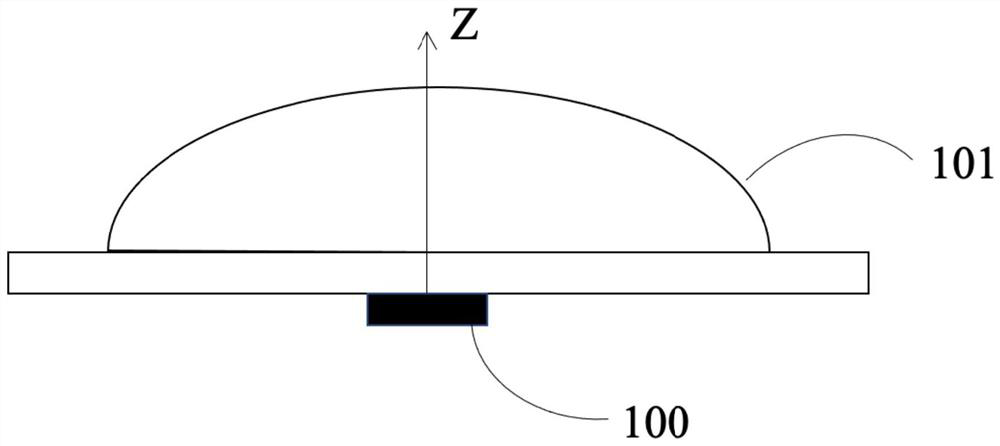

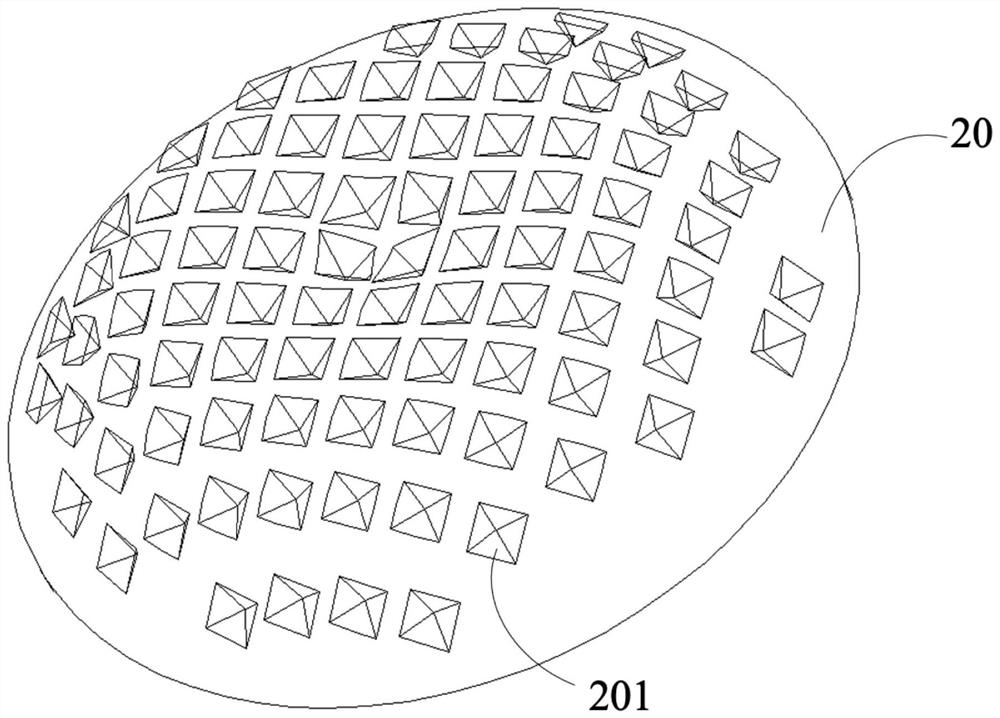

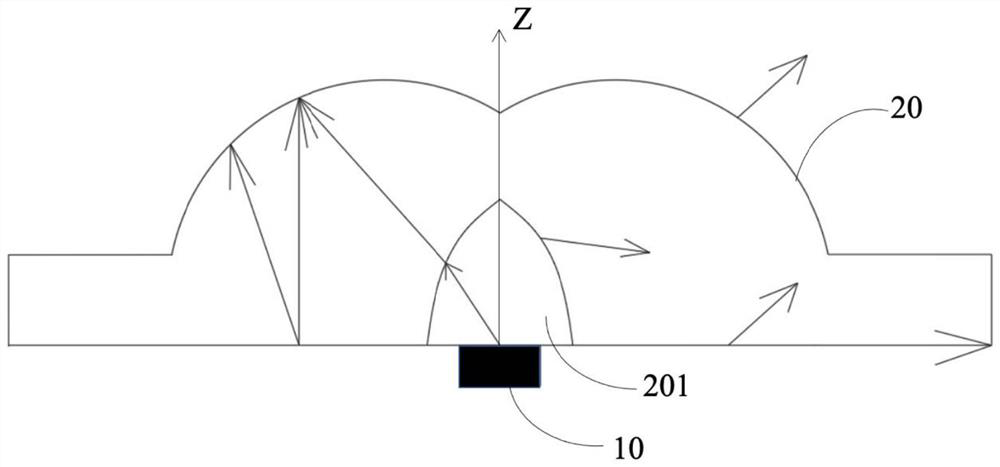

[0033] First, through Figure 2-6 , the direct-type light-emitting device according to Embodiment 1 of the present invention will be described. The direct-type light-emitting device of Embodiment 1 of the present invention, such as image 3 As shown, a direct lighting device includes a plurality of LED light sources 10 and a plurality of optical lenses 20 coupled to the LED light sources 10 and positioned above the LED light sources 10 . The optical lens 20 is provided with a hollow structure 201 which is radially symmetrical to the light source and the optical axis of the optical lens 20 . Such as figure 2 As shown, the outer surface of the optical lens 20 is provided with a micro-diffusion structure 202 . In the hollow structure 201, the angle between the tangent plane of the surface near the optical axis and the optical axis is smaller than the angle between the tangent plane of the surface far from the optical axis and the optical axis; The density of the micro-diffus...

Embodiment 2

[0040] Please refer to Figure 7 , is a schematic structural view of the optical lens of the direct light-emitting device according to Embodiment 2 of the present invention. Only the differences between Embodiment 2 and Embodiment 1 will be described below, and the similarities will not be repeated here.

[0041] The hollow structure 201 forms a near-cone mechanism 202 along the optical axis, and the top angle of the near-cone mechanism 202 is farther away from the LED light source 10 . The reflectance of the light emitted by the LED light source 10 at the apex angle of the near-cone mechanism 202 is higher, so that the direct-type light-emitting device can achieve a wider light transfer function and a larger diffusion angle. A plurality of optical lenses 20 are integrally connected.

Embodiment 3

[0043] Please refer to Figure 8 , is a schematic structural view of the optical lens of the direct light-emitting device according to Embodiment 3 of the present invention. In the following, only the differences between Embodiment 3 and Embodiment 1 will be described, and the similarities will not be repeated here.

[0044] The optical lens 20 forms a near-cone structure 202 along the optical axis, and the top angle of the near-cone structure 202 is close to the LED light source 10 . The reflectance of the light emitted by the LED light source 10 at the apex angle of the near-cone mechanism 202 is higher, so that the direct-type light-emitting device can achieve a wider light transfer function and a larger diffusion angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com