Method and system for detecting influence of combustion chamber machining parameters on emission based on big data

A technology of processing parameters and detection methods, applied in special data processing applications, design optimization/simulation, chemical process analysis/design, etc., can solve problems such as diesel engines exceeding emission limits and failing to meet emission consistency requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

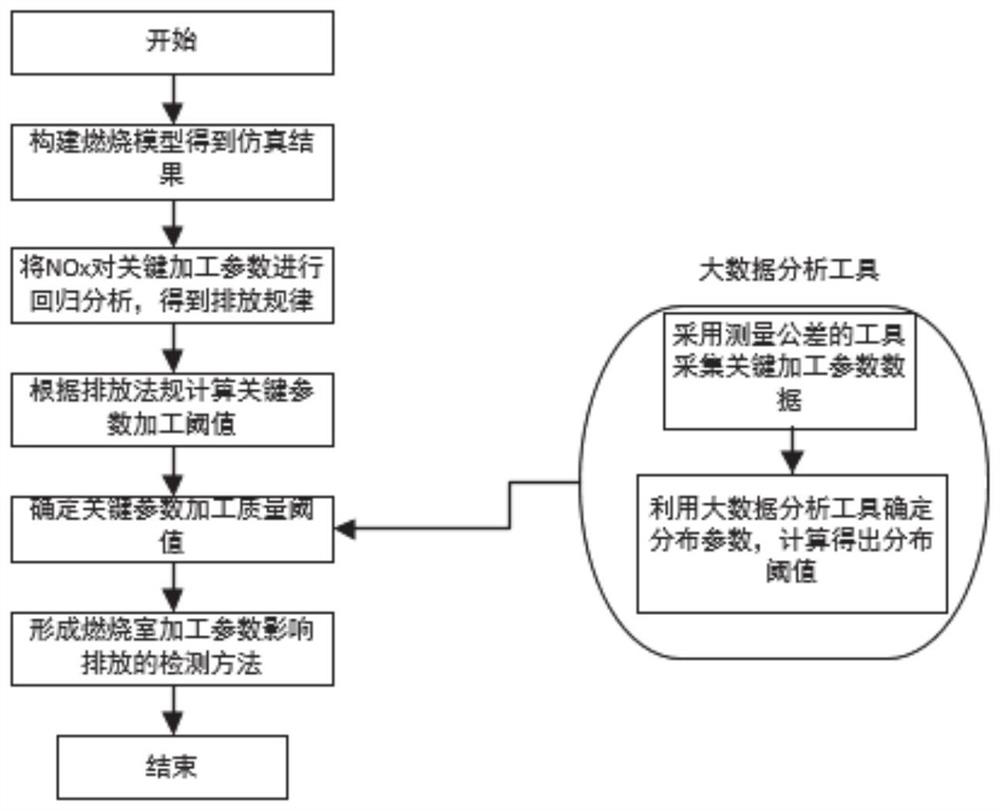

[0035] This embodiment provides a big data-based detection method for the influence of combustion chamber processing parameters on emissions, which can analyze the impact of changes in diesel engine piston combustion chamber processing parameters on the consistency of NOx emissions, such as figure 1 shown, including:

[0036] Construct a diesel engine combustion model, select different processing parameters of the piston combustion chamber for simulation calculation, and obtain the simulation results;

[0037] Analyze the simulation results to obtain the influence law of each parameter change on the consistency of NOx emissions; calculate the processing threshold of key parameters according to the law;

[0038] Obtain key processing parameter data, and use big data tools to determine the distribution range of processing parameters.

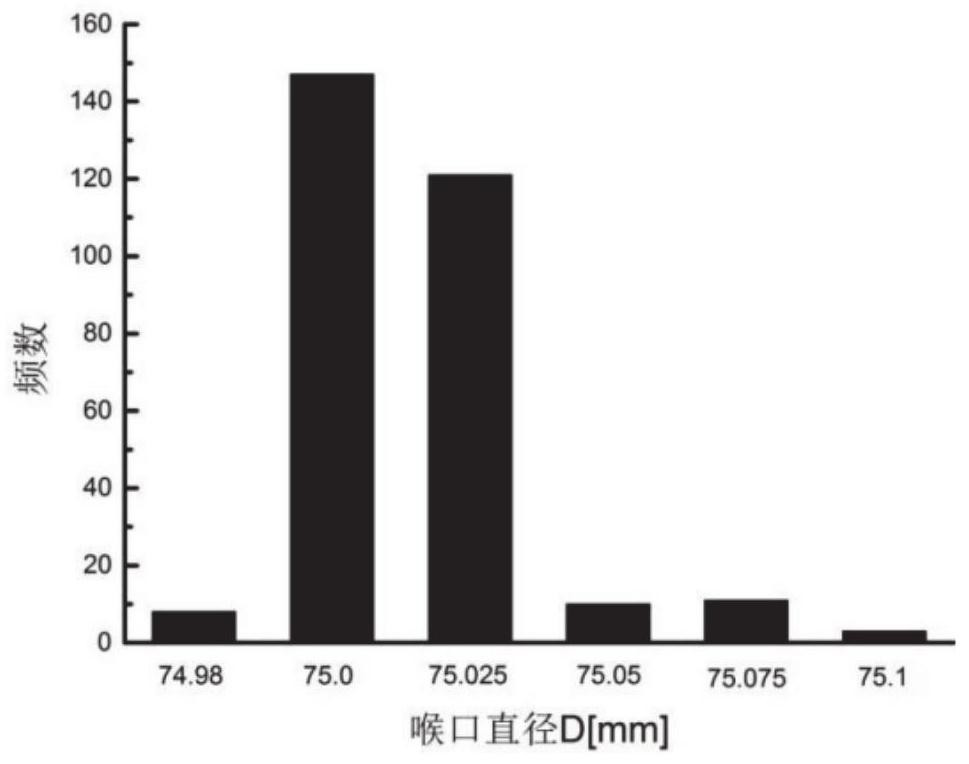

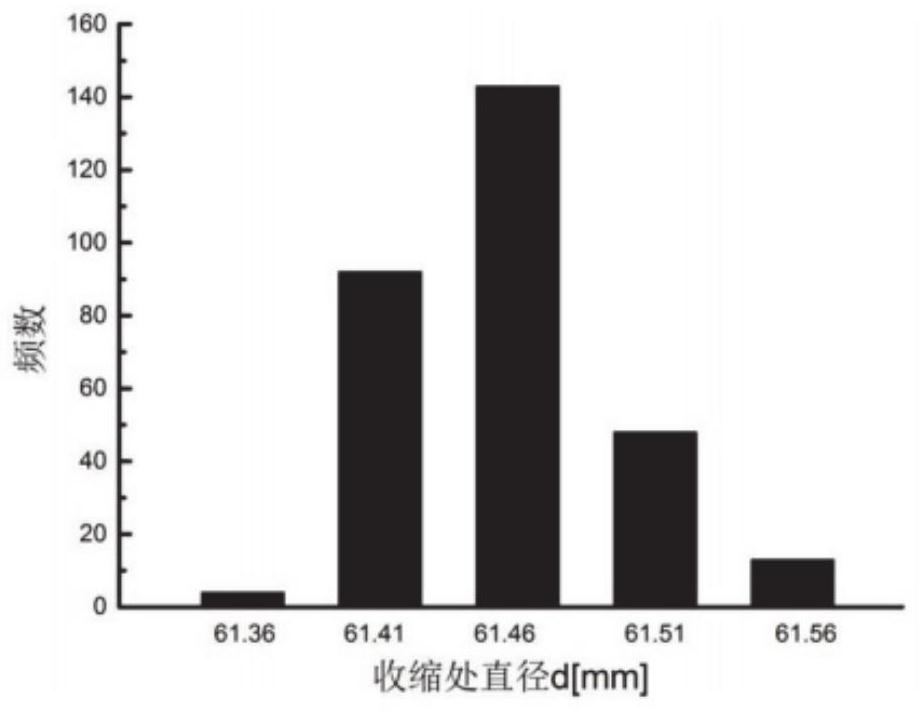

[0039] Further, first select the key parameters (throat diameter, constriction diameter and combustion chamber depth) in the process of combusti...

Embodiment 2

[0060] This embodiment provides a diesel engine combustion chamber processing quality inspection system based on big data analysis, including:

[0061] The combustion model building module is configured to: build a diesel engine combustion model, select different piston combustion chamber processing parameters for simulation calculation, and obtain simulation results;

[0062] The processing threshold calculation module is configured to: analyze the simulation results to obtain the influence law of each parameter change on the NOx emission consistency; calculate the key parameter processing threshold according to the law;

[0063] The distribution threshold calculation module is configured to: acquire key processing parameter data, and use big data tools to determine the distribution range of the processing parameter.

Embodiment 3

[0065] This embodiment provides an electronic device, including a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the program, the combustion chamber based on big data is realized. Process parameters affect emission detection methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com