Turbine blade automatic production line storage location management method and management system

A technology for automated production lines and turbine blades, applied in office automation, manufacturing computing systems, database indexes, etc., can solve the lack of effective management of cross-material coding data and complex process information, and the ineffectiveness of automation technology and information technology Combination and other issues to achieve the effect of easy quality traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

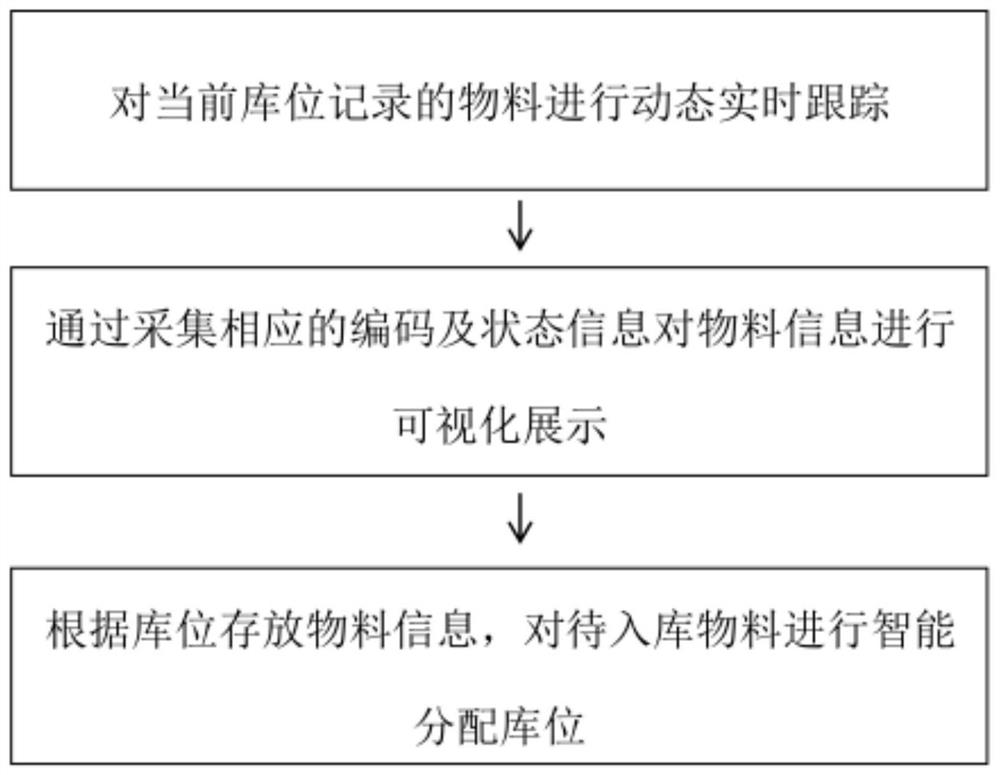

[0030] A storage location management method for a turbine blade automation production line, such as figure 1 shown, including the following steps:

[0031] Dynamic real-time tracking of the materials recorded in the current location;

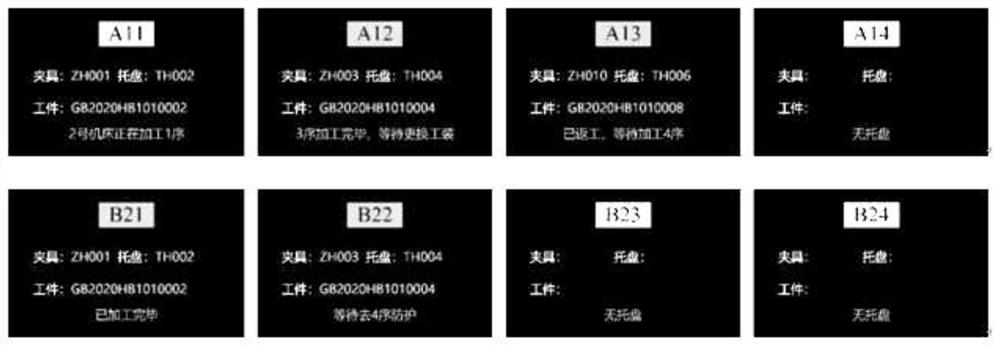

[0032] Visually display material information by collecting corresponding codes and status information;

[0033] According to the material information stored in the warehouse location, intelligently allocate the warehouse location for the incoming materials.

[0034] Among them, this management method can record all the dynamic information of the blade processing process in the order, and display the material information stored in the current warehouse location to the operator in real time with the help of the WINCC interface, so as to realize the warehouse location of the aeroengine turbine blade automation production line Systematic standardized management and information display.

Embodiment 2

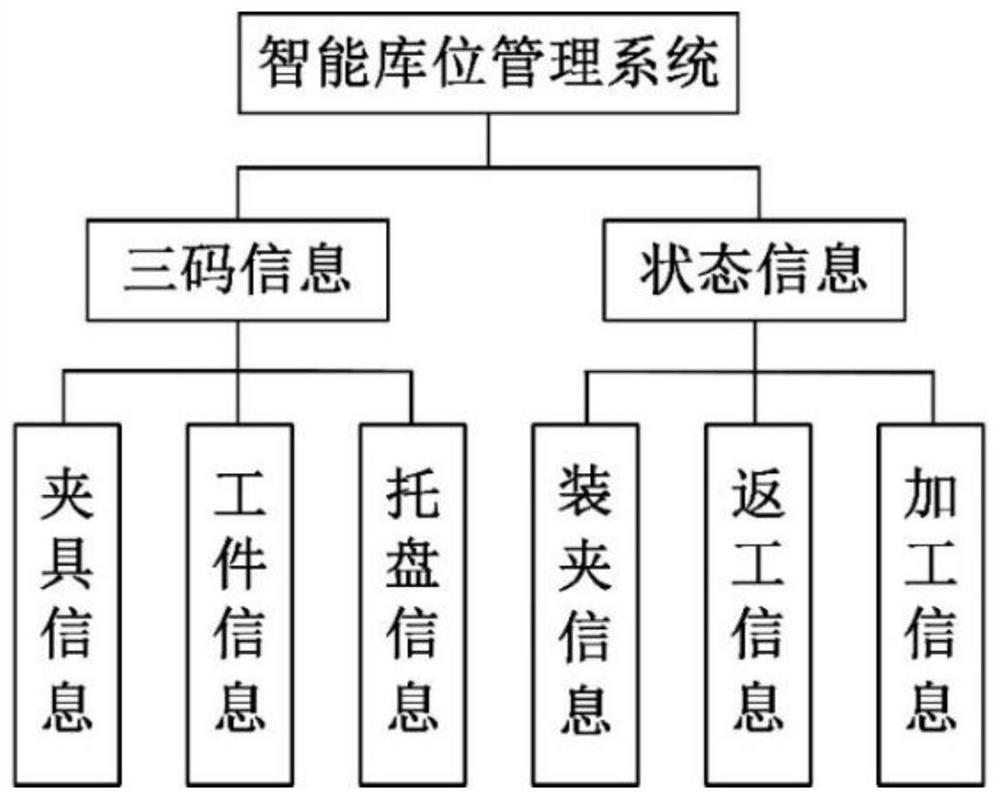

[0036] A turbine blade automatic production line inventory management system, including a dynamic information recording module, an information display module and a priority processing module, the dynamic information recording module is used to record processing dynamic information of different types of turbine blades, and the information display module is used for query and display the processing dynamic information of different types of turbine blades. The priority processing module is used to intelligently allocate storage locations for incoming materials. Among them, the processing dynamic information includes the process flow of the blades and the assembly materials used. The dynamic information recording module tracks in real time The recorded processing dynamic information is visualized through the information display module, and the dynamic information recording module is used to record fixture information, workpiece information, pallet information, clamping information, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com