A packing and sealing process for carton packaging production and a device for realizing the process

A technology for packaging and sealing machines and boxes, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of high maintenance rate, high cost, increased labor intensity of workers, etc., to reduce investment and operating costs, and equipment structure. And the effect of simple control and simplified packaging and packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

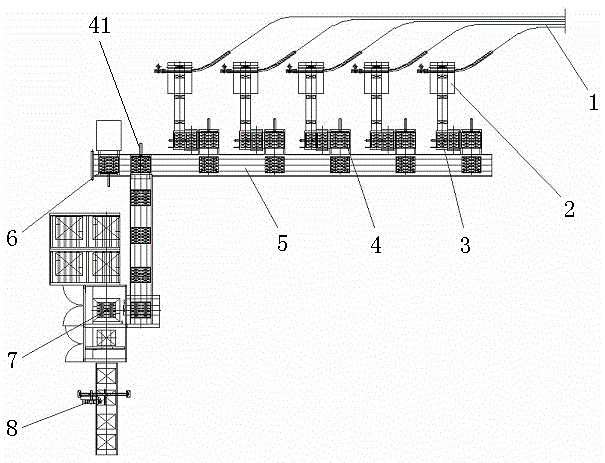

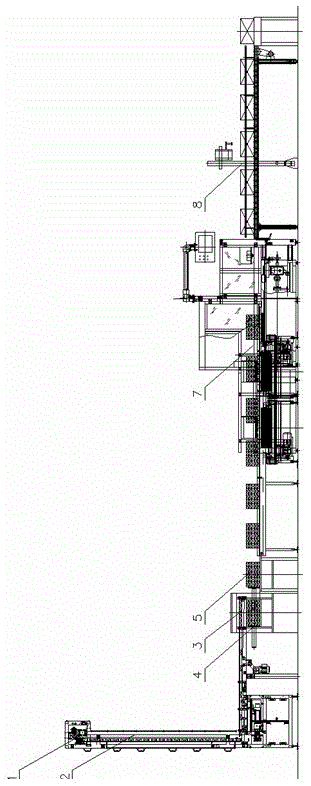

[0031] See attached figure 1 Shown, a kind of packing and sealing process used on the box packing production line comprises the following steps:

[0032] A. Cartons of the same brand from five packaging units are transported to the single-lane packing machine 2 through the single-lane conveyor 1 of the corresponding five stacking lines, and the single-lane packing machine 2 sends the cartons from the high position to the low position Afterwards, continue to deliver in the stacking device 3 through the horizontal conveyor again, pile up into five layers of one pile, five one-layer carton stacks of twenty-five in total;

[0033] B, the carton stack of step A is pushed onto the pallet conveyor 5 by the first stacking device 4. The first stacking device 4 is provided with a barcode read-write head, and stores a stack of carton stacks, and the pallet conveyor 5 is a linear conveyor, and the pallet conveyor 5 is provided with a readable and writable barcode according to the conveyi...

Embodiment 2

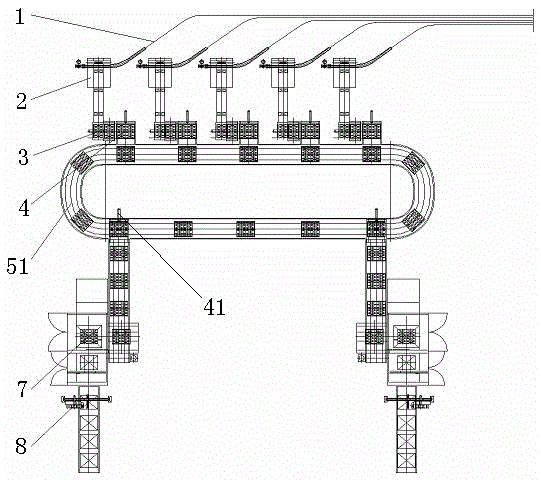

[0037] See attached figure 2 Shown, a kind of packing and sealing process used on the box packing production line comprises the following steps:

[0038] A. Cartons of different brands from five packaging units are transported to the single-lane packing machine 2 through the single-lane conveyor 1 of the corresponding five stacking lines, and the single-lane packing machine 2 sends the cartons from the high position to the low position Afterwards, continue to deliver in the stacking device 3 through the horizontal conveyor again, pile up and pile up into five layers, one layer, five cartons, one layer, and a total of twenty-five cartons;

[0039] B, the carton stack of step A is pushed onto the pallet conveyor 51 by the first stacking device 4. The first stacking device 4 is provided with a barcode read-write head, and stores two stacks of carton stacks, and the pallet is transported The machine 51 is an endless conveyor, and the pallet conveyor 51 is provided with a readable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com