Manufacturing tool for calcium phosphate bone cement round rod and manufacturing method for bone cement round rod manufacturing

A technique for making calcium phosphate bone cement and tools, which is applied in the field of medical devices, and can solve problems such as overflow, bone cement collapsing in case of blood, and false filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

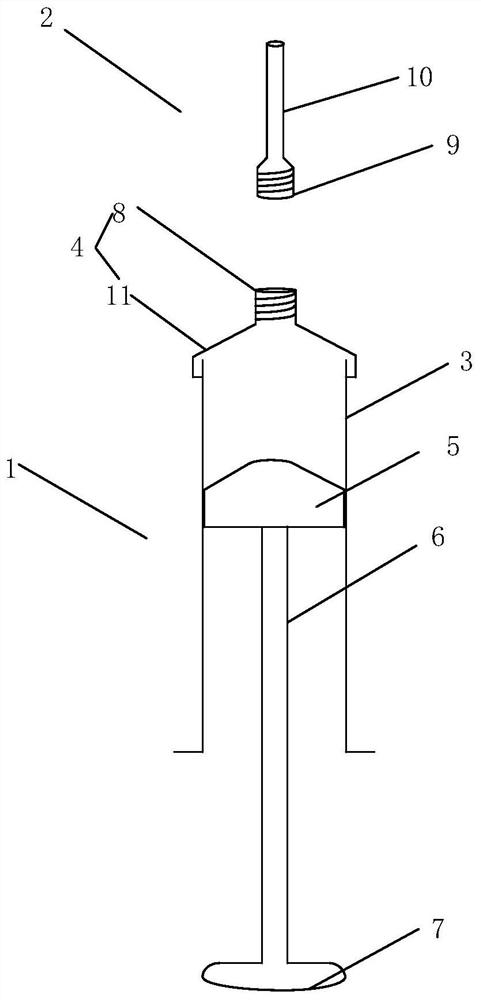

[0023] The present embodiment provides a calcium phosphate bone cement round rod manufacturing tool, such as figure 1 As shown, the calcium phosphate bone cement round rod manufacturing tool includes a bone cement syringe 1 and a forming nozzle 2; the bone cement syringe 1 includes a bone cement injection cylinder 3, a syringe head 4, a sliding plug 5, a push rod 6 and a handle 7. The front end of the bone cement injection cylinder 3 is provided with an opening for injecting calcium phosphate bone cement, the syringe head 4 is detachably connected to the front opening of the bone cement injection cylinder 3, and the push rod 6 is connected to the Between the sliding plug 5 and the handle 7, the sliding plug 5 can slide back and forth and fit on the inner wall of the bone cement injection cylinder 3; the forming nozzle 2 is detachably connected to the syringe head 4, The forming nozzle 2, the injector head 4 and the bone cement injection cylinder 3 are in communication.

[002...

Embodiment 2

[0026] Calcium phosphate bone cement round rod making tool as described in embodiment 1, such as figure 1 As shown, the syringe head 4 includes a syringe head front 8 and a syringe head rear 11, the syringe head front 8 is in the shape of a cylinder with both ends open, and the syringe head rear 11 is in the shape of a circular truncated cone with both ends open , the front part 8 of the syringe head is connected to the smaller end of the rear part 11 of the syringe head.

[0027] In the calcium phosphate bone cement round rod manufacturing tool of this embodiment, the calcium phosphate bone cement in the bone cement injection cylinder 3 flows out through the rear part 11 of the syringe head, the front part 8 of the syringe head and the forming nozzle 2 in sequence to form the calcium phosphate bone cement The back part 11 of the syringe head is in the shape of a truncated cone with openings at both ends, and the diameter decreases successively from back to front, so that the ...

Embodiment 3

[0029] Calcium phosphate bone cement round rod making tool as described in embodiment 2, such as figure 1 As shown, the rear part 11 of the syringe head is provided with an internal thread, and the front end of the bone cement injection cylinder 3 is provided with an external thread, and the rear part 11 of the syringe head is threadedly connected with the front end of the bone cement injection cylinder 3 . In this way, the rear part 11 of the syringe head and the front end of the bone cement injection cylinder 3 are not only conveniently connected and easy to operate, but also can be sealed and connected, so that the calcium phosphate bone cement in the bone cement injection cylinder 3 can be completely formed. The nozzle 2 sprays out to form a calcium phosphate bone cement round rod, which has better utility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com